Polyethylene film resistant to high-temperature steaming and production process of polyethylene film

A polyethylene film and production process technology, applied in the packaging field, can solve the problems of low heat-sealing strength, high energy consumption, and high heat-sealing temperature of CPP film, and achieve broad market application prospects, excellent optical properties, and wide heat-sealing window Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

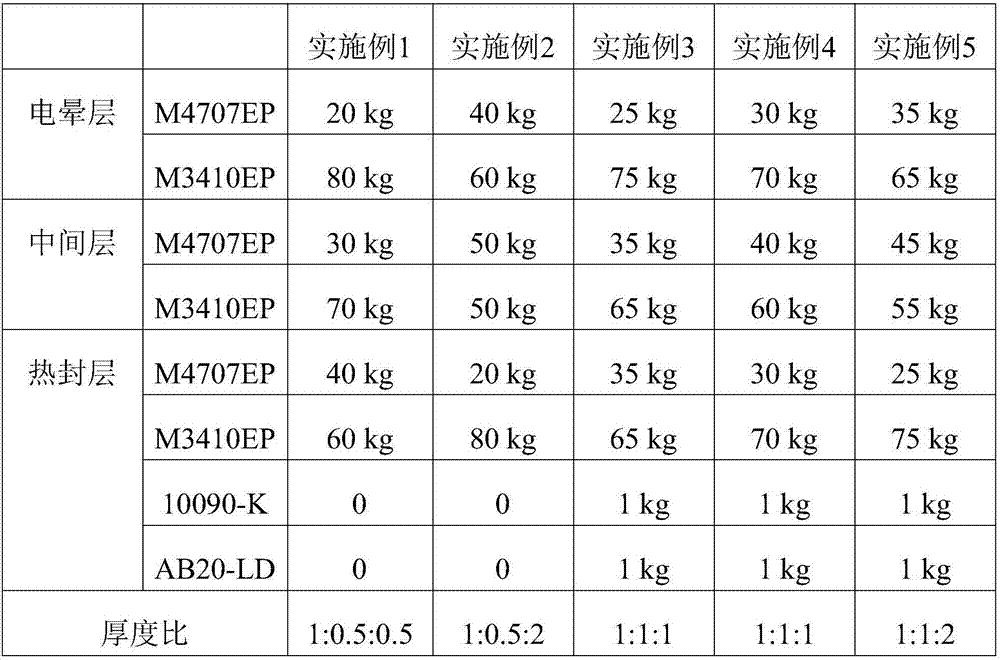

[0049] The raw material composition and formula of the polyethylene film of Examples 1-5 are shown in Table 1.

[0050] M3410EP and M4707EP are medium and high-density metallocene PE produced by TOTAL, 10090-K is the smooth agent with color matching, and AB-20LD is the anti-blocking agent of Beijing Yalun.

[0051] Table 1

[0052]

[0053] Wherein the thickness ratio is the thickness ratio of the corona layer, the intermediate layer and the heat-sealing layer.

[0054] figure 1 It is a flow chart of the production process of the polyethylene film of the present invention. The polyethylene film of the present invention is made of PE film through a film blowing process from PE particles.

[0055] The specific production process is as follows:

[0056] Co-extruding the raw materials of the corona layer, the middle layer and the heat-sealing layer to obtain a hot-melt drum film comprising the corona layer, the middle layer and the heat-sealing layer in sequential contact; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com