Thin-wall insulated electric wire material for automobile and preparation method of electric wire material

A thin-walled insulation and wire material technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of long-term aging resistance, low temperature and high temperature resistance, burning without dripping and liquid resistance, etc., to achieve The effect of low cost, short process flow and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepare the thin-walled insulated wire material for automobiles as follows:

[0047] Prepare plasticizer: weigh the halogenated bisphosphonate compound FR-V6, di-n-hexyl sebacate and 2,2,4-trimethyl-1,3 -Pentylene glycol diisobutyrate, mixing the weighed raw materials uniformly to obtain a plasticizer;

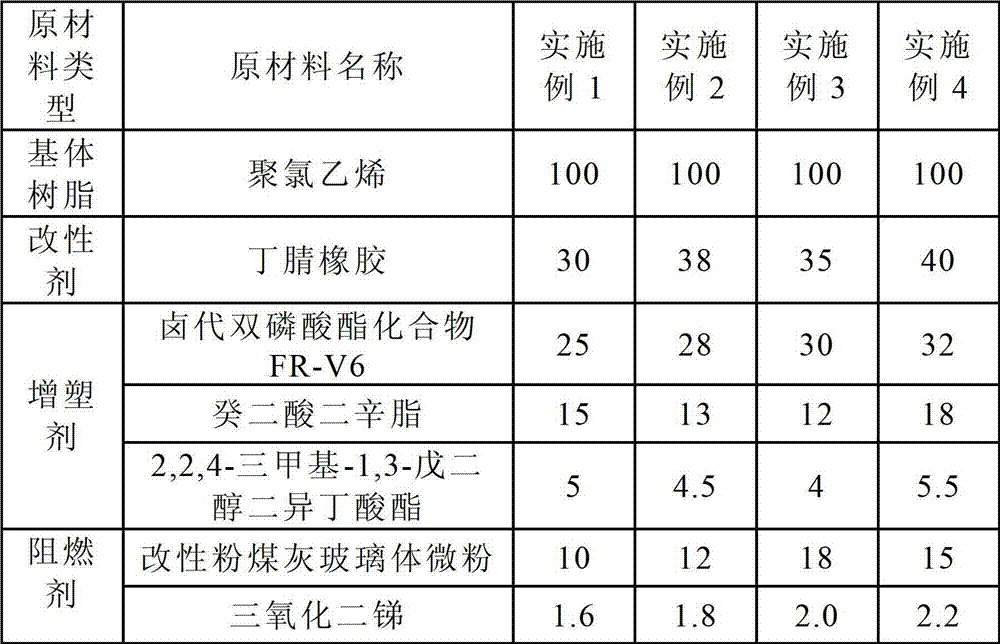

[0048] Compounding: Weigh polyvinyl chloride according to the weight of Example 1 in Table 1, pour it into a high mixer, stir evenly, then pour the plasticizer prepared above, stir at a high speed and heat, until the plasticizer After being completely absorbed by the polyvinyl chloride, add modifiers, flame retardants, fillers, stabilizers, wear-resistant agents and auxiliary agents weighed according to the weight parts of Example 1 in Table 1, stir at a high speed, and the stirring temperature is 80 ℃, until the material is completely uniform;

[0049] Processing and granulation: Discharge the above-mentioned mixed materials from the high-speed mixer, put them into t...

Embodiment 2-4

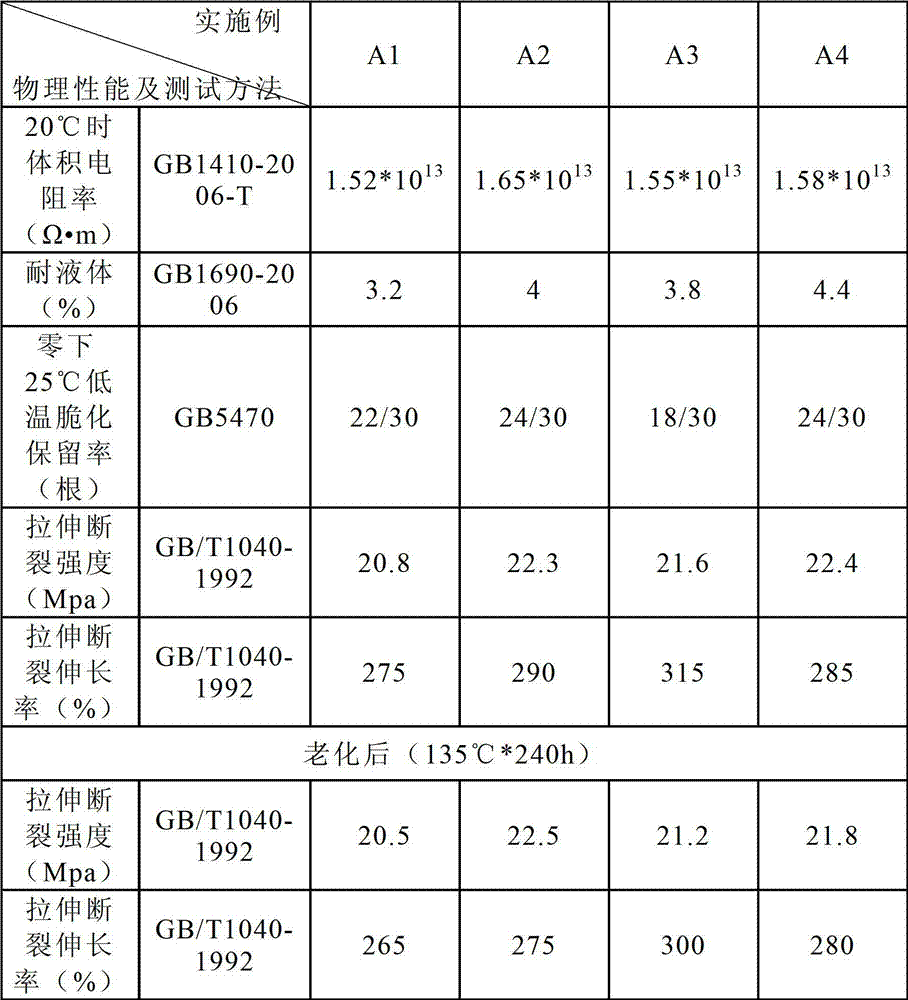

[0054] According to the method of Example 1 and the raw material components and parts by weight of Examples 2-4 in Table 1, the thin-walled insulated wire materials A2-A4 for automobiles were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com