Environment-friendly epoxy intumescent fire-retardant coating and preparing method thereof

A kind of fireproof coating, expansion technology, applied in fireproof coating, epoxy resin coating, coating, etc., to achieve excellent acid resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

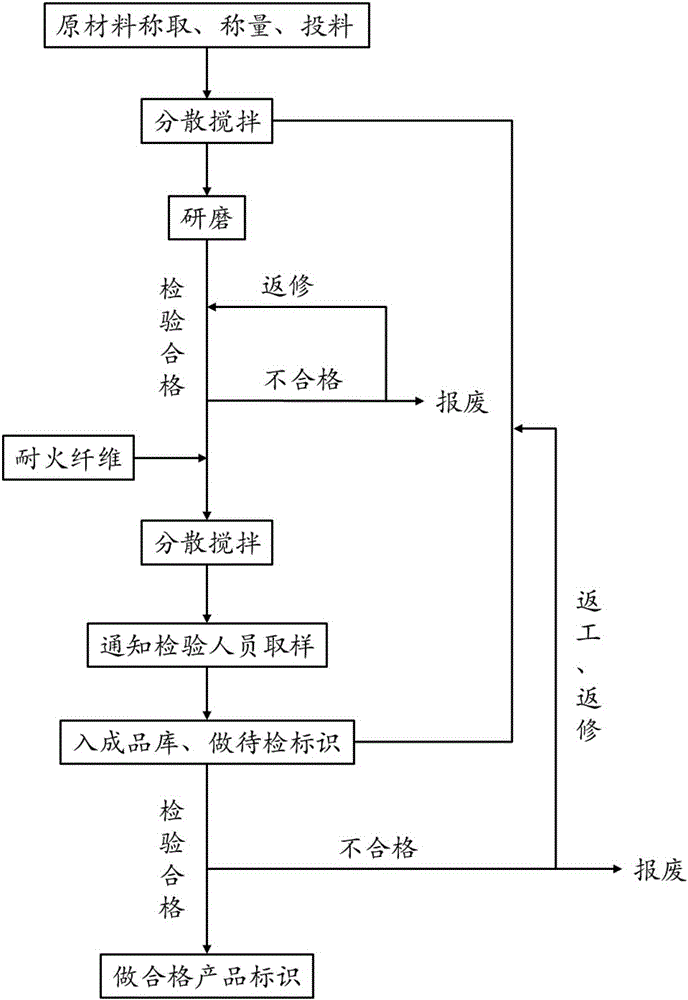

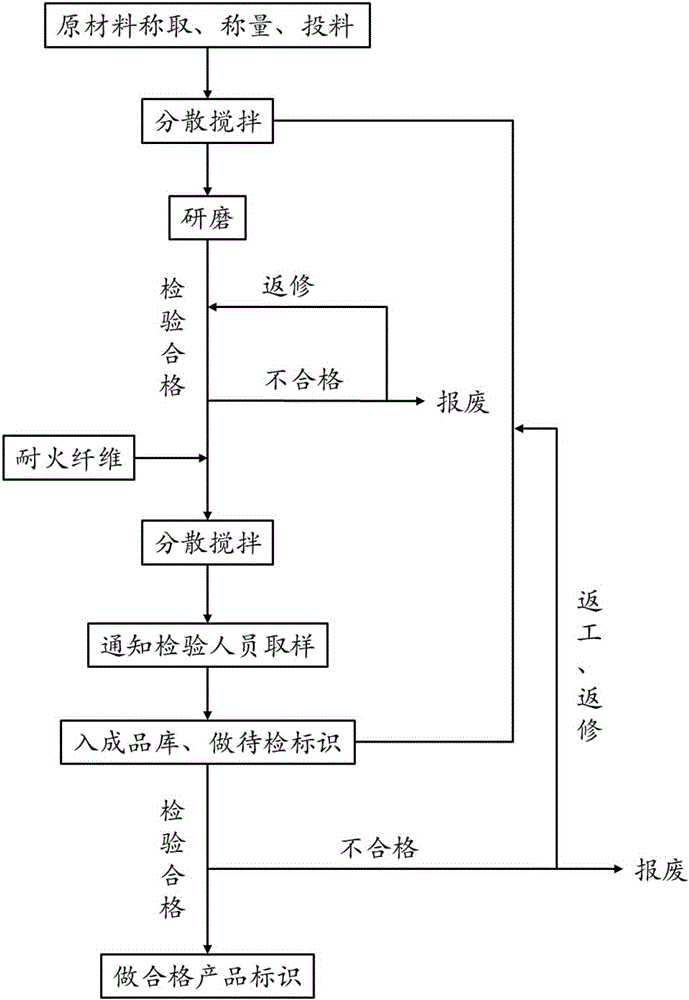

Method used

Image

Examples

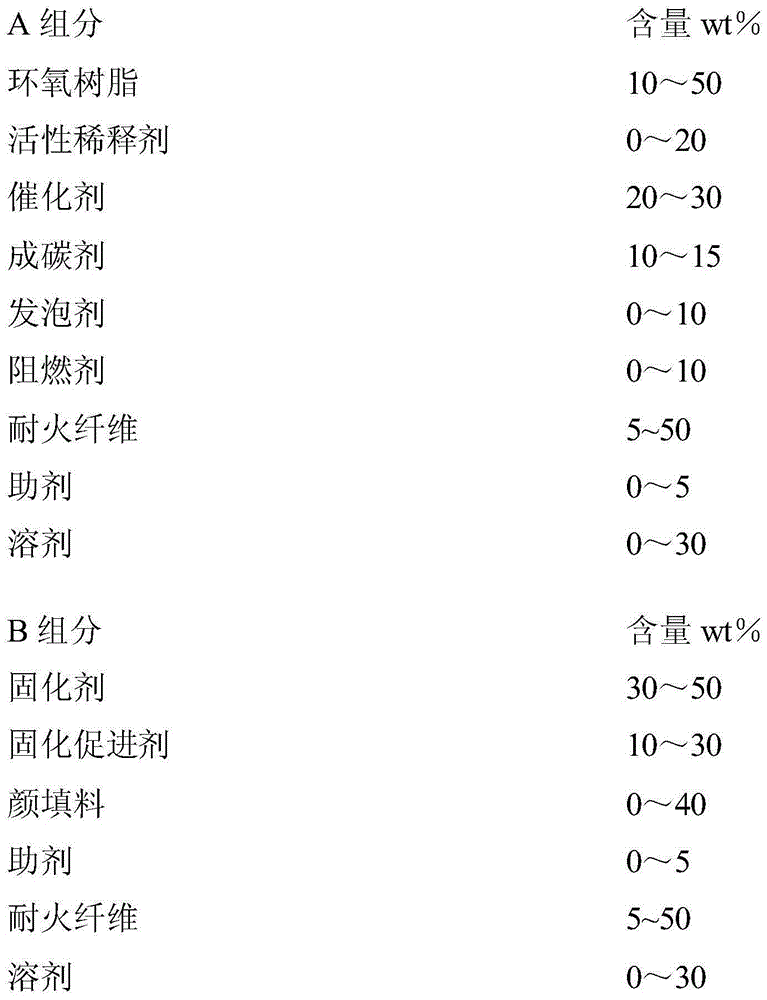

Embodiment 1

[0026]

[0027]

[0028] A and B are used in a ratio of 1.6:1.

[0029] The tested paint film properties are as follows.

[0030]

[0031] The comparison of the effects of different dosages of curing accelerators on the parameters of the intumescent carbon layer and the fire performance of the fire retardant coating is shown in the table below. The test conditions are that the flame temperature is 2000°F, the coating thickness is 1mm, and the fire test time is 15min. Except for the curing accelerator, the proportions of the raw materials are the same, as in Example 1.

[0032] Table 1 Comparison of parameters and fire performance of intumescent carbon layer of fire retardant coatings

[0033]

[0034]

Embodiment 2

[0036]

[0037] A and B are used in a ratio of 1:1.

[0038] The tested paint film properties are as follows.

[0039]

[0040] The effect of different additions of refractory fibers on the parameters and fire performance of the expanded carbon layer of the fire retardant coating is shown in the table below. The test conditions are: flame temperature of 2000°F, coating thickness of 1mm, and fire test time of 15min. Except for refractory fibers, the proportions of the raw materials used are the same, as in Example 2.

[0041] Table 2 Comparison of parameters and fire performance of intumescent carbon layer of fire retardant coatings

[0042]

Embodiment 3

[0044]

[0045]

[0046] A and B are used in a ratio of 4:1.

[0047] The tested paint film properties are as follows.

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com