Choke

A technology of chokes and plate-shaped objects, which is applied in the direction of transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, electrical components, etc., which can solve the problems of unautomated production, high labor cost, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

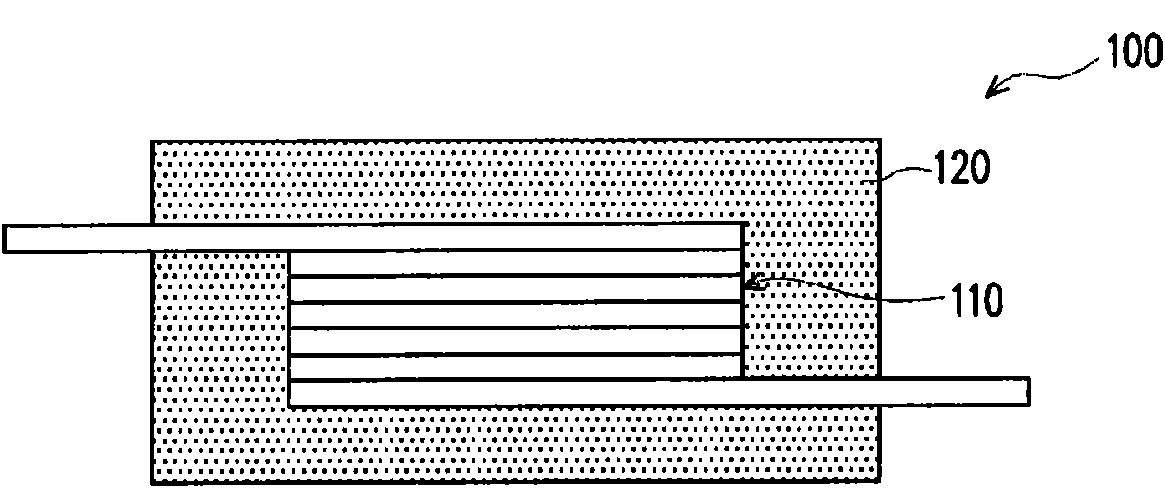

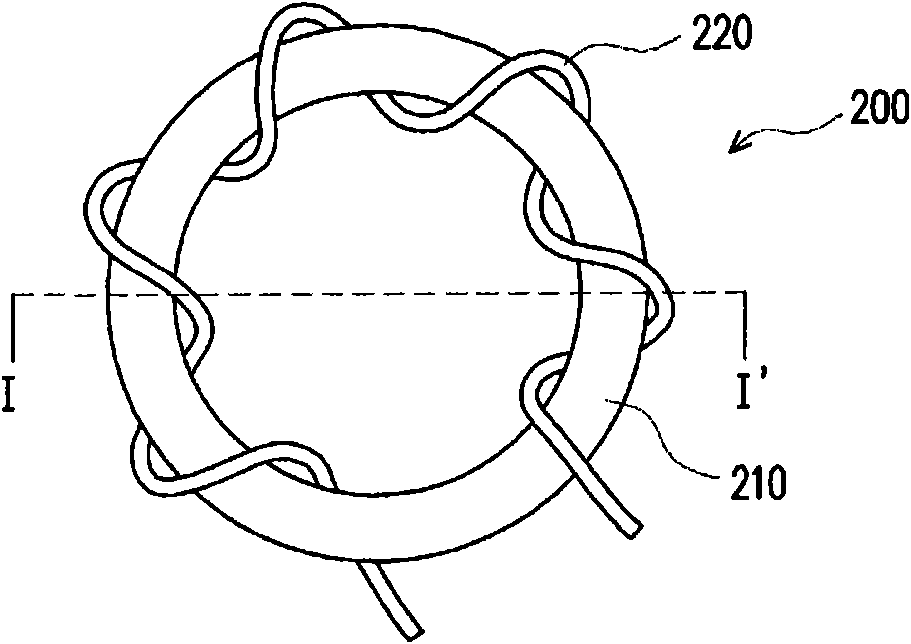

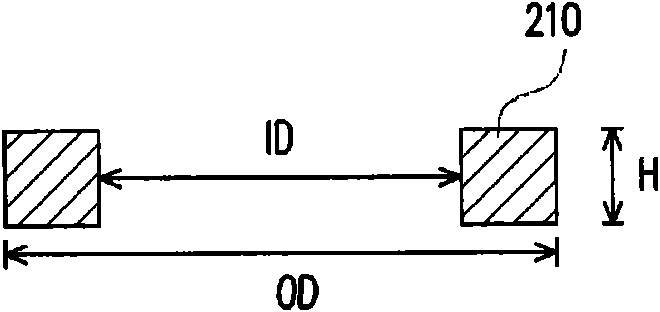

[0038] image 3 It is a cross-sectional view of a choke according to an embodiment of the present invention. Please refer to image 3 , the choke 300 of this embodiment includes a drum core 310 and a wire 320 . The drum-shaped magnetic core 310 includes a central column 312, a first plate-shaped body 314 and a second plate-shaped body 316, and the two ends of the central column 312 are respectively connected to the first plate-shaped body 314 and the second plate-shaped body 316 . The material of the drum-shaped magnetic core 310 is a ferrous alloy, and the ferrous alloy can be an iron-silicon aluminum alloy, an iron-nickel-molybdenum alloy, an iron-nickel alloy, or an amorphous (Amorous) alloy. The drum-shaped magnetic core 310 is formed by powder molding and then sintered at a temperature above 300° C., and a preferred sintering temperature is above 600° C. The magnetic permeability u (Permeability) of the drum core 310 is, for example, 60-300, preferably 60-125. The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com