Mining method for underground mine with ore-drawing roadway arranged between every two adjacent stopes

A mining method and mine roadway technology, applied in underground mining, surface mining, mining equipment, etc., can solve the problems of high support cost, unresolved, difficult to recycle, etc., achieve less large ore block rate, and small mining engineering quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

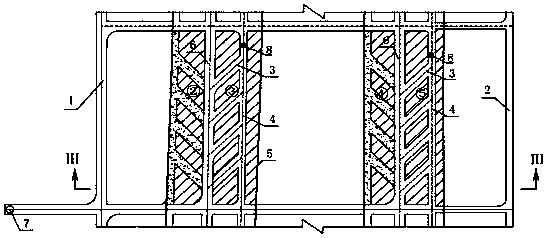

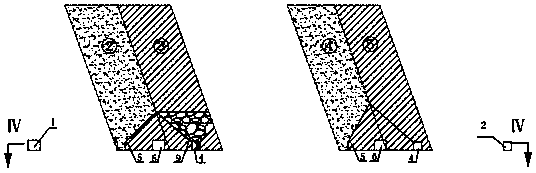

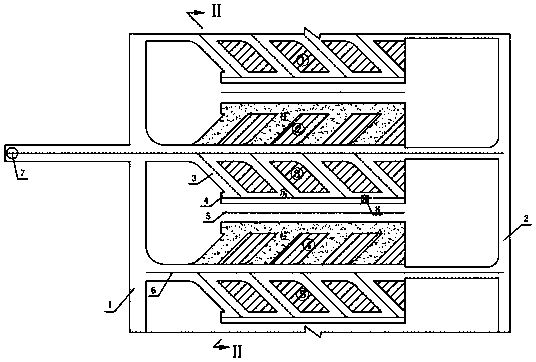

[0031] See attached picture.

[0032] A certain iron ore belt has no fractures, the mechanical strength of the rock is high, and the stability of the ore rock is good. The stope is 50m long, 16.0m wide, and 50m high, avoiding the construction of the mining roadway in the filling body, which is difficult to construct in the filling body, with high safety risks, high costs, and a large amount of mining work. In order to solve this situation, a mining method in which one mining roadway can meet the requirements of two adjacent stopes is adopted. The specific implementation steps are as follows:

[0033] Stope layout:

[0034] The ore body is divided into several ore blocks along the ore body trend, and the length of the ore blocks is 40-80m.

[0035] Along the ore body trend, the hanging wall along the vein return airway 2 and the footwall along the vein transportation lane 1 are arranged. The footwall along the vein transportation lane 1 is arranged outside the ore body and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com