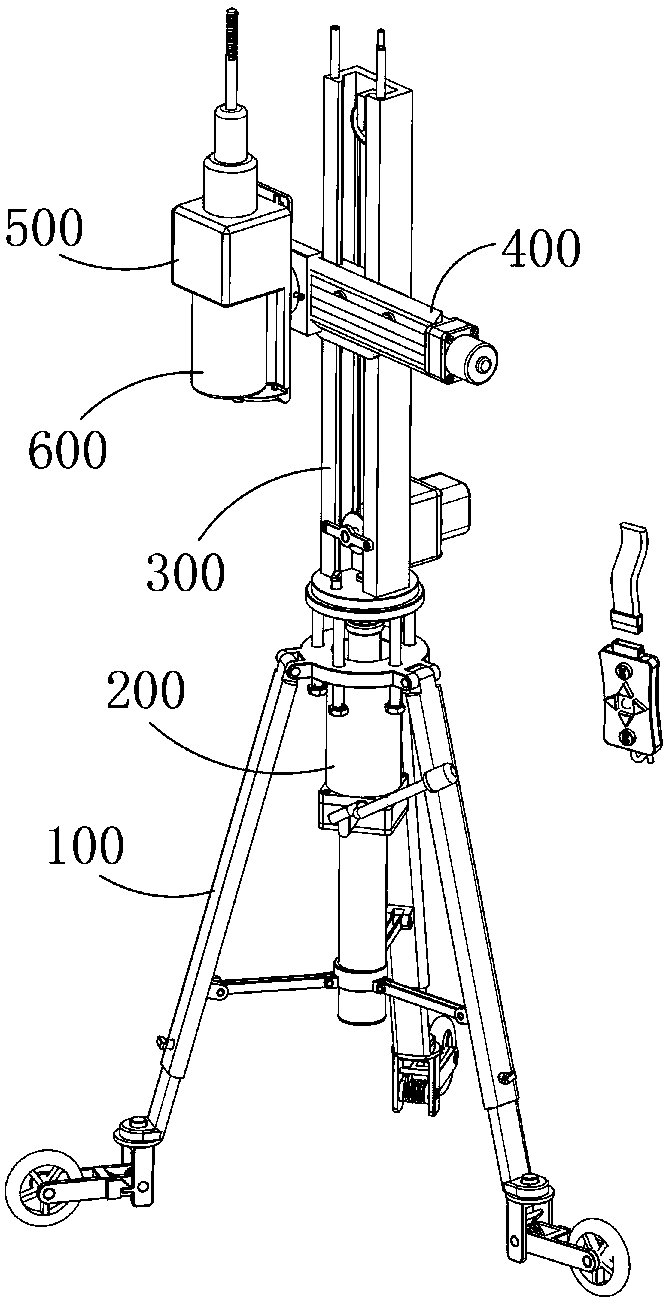

High-precision crown drilling machine used for housing construction ceiling and capable of performing continuous hole drilling

A high-precision, architectural technology, applied in the direction of drilling/drilling equipment, portable drilling rigs, workbenches, etc., can solve the problems of low drilling efficiency, worker fatigue, and inconvenient operation of workers, so as to improve drilling efficiency and reduce labor force , the effect of convenient alignment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

[0071] Such as Figure 5-7 As shown, the above-mentioned power mechanism a330 includes an adjustment motor 331, a fixed pulley a332, a fixed pulley b333, and a connecting rope 334. A fixed bracket 350 and a support rod 340 are installed in the described adjustment slide rail 310, and the support rod 340 is provided with a connection hole, the adjustment slide rail 310 is provided with a through hole, the adjustment motor 331 is fixedly installed on the adjustment slide rail 310 and the power output shaft of the adjustment motor 331 passes through the hole and is located in the connection hole, the fixed pulley a332 The fixed pulley b333 is movably mounted on the fixed bracket 350, and one end of the connecting rope 334 is connected with the fixed pulley a332, bypasses the fixed pulley b333, and the other end is connected with the set pulley b333. It is connected with the slider section of the adjustment slider 320, specifically, the slider section of the adjustment slider 320 ...

no. 2 approach )

[0082] The difference between this embodiment and the first embodiment mainly lies in the structure of the power mechanism a330.

[0083] Such as Figure 12-13 As shown, the above-mentioned power mechanism a330 includes an adjustment motor 331, a gear 335, and a rack 336. The bottom surface of the installation section of the adjustment slider 320 is provided with a slide plate extending toward the ground, and the slide plate is provided with perforations. The adjustment motor 331 is fixedly installed on the slide plate and the power output shaft of the adjustment motor 331 passes through the hole and is located in the adjustment slide rail 310. The gear 335 is fixedly connected to the power output shaft of the adjustment motor 331, and the rack 336 is fixedly installed in the adjustment slide rail 310 and the extension direction of the rack 336 is parallel to the guiding direction of the adjustment slide rail 310, and the rack 336 is engaged with the gear 335; the process of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com