Integrated magnetic structure

A magnetic integration, magnetic core technology, applied in the electromagnetic field, can solve the problems of loss and volume increase, increase the air gap, insufficient use of some magnetic cores of the transformer, etc., to reduce the volume, reduce the volume of the magnetic core, and increase the power The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0025] In order to reduce the overall volume of the magnetic element and increase the power density of the power electronic converter, the present invention proposes a magnetic integration structure that can make full use of the magnetic core material and is beneficial to reduce the volume of the magnetic element.

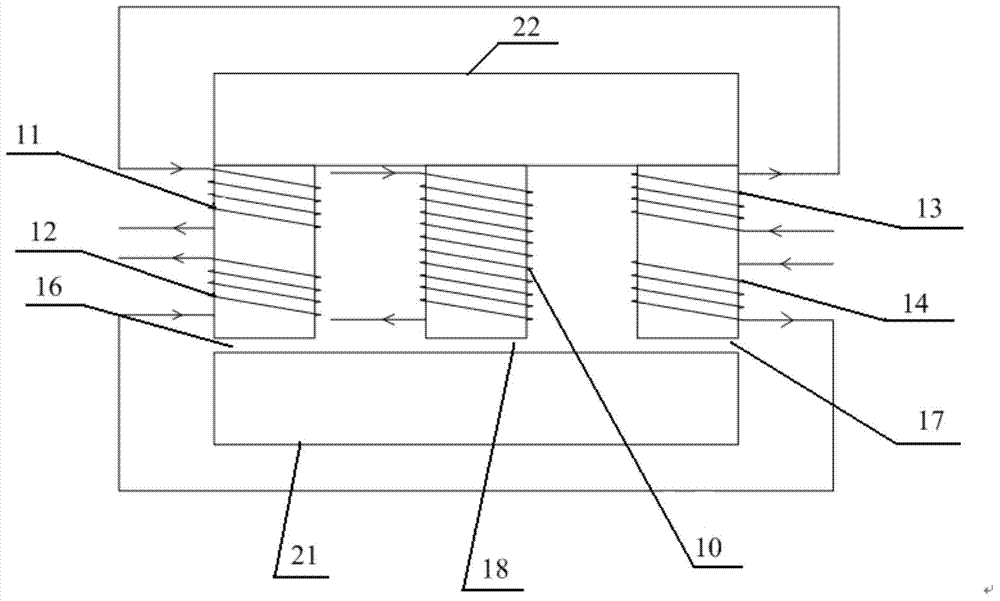

[0026] Such as Figure 2a Shown is a schematic structural diagram of the magnetic integration structure in the first embodiment of the present invention. In this embodiment, the magnetic integration structure is used as an example for description of the magnetic integration structure of a transformer and an inductor. The magnetic integration structure includes a flat "Sun"-shaped magnetic core, which is formed by stacking an E-shaped magnetic core 22 and an I-shaped magnetic core 21 . The inductance winding is wound on the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com