Thermal management system and control method for coolant flow to controllable battery pack

A thermal management system and cooling liquid flow technology, applied in battery/fuel cell control devices, battery/battery traction, secondary batteries, etc., can solve the problem of large temperature difference between the battery inlet and outlet, affecting the life of the power battery, and affecting the consistency of the cells In order to achieve the effect of simplifying the design, eliminating the fixedness and reducing the difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

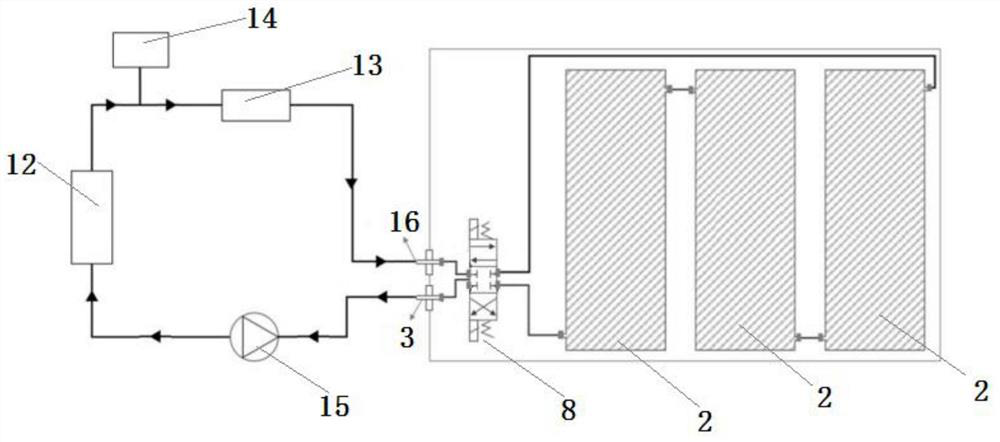

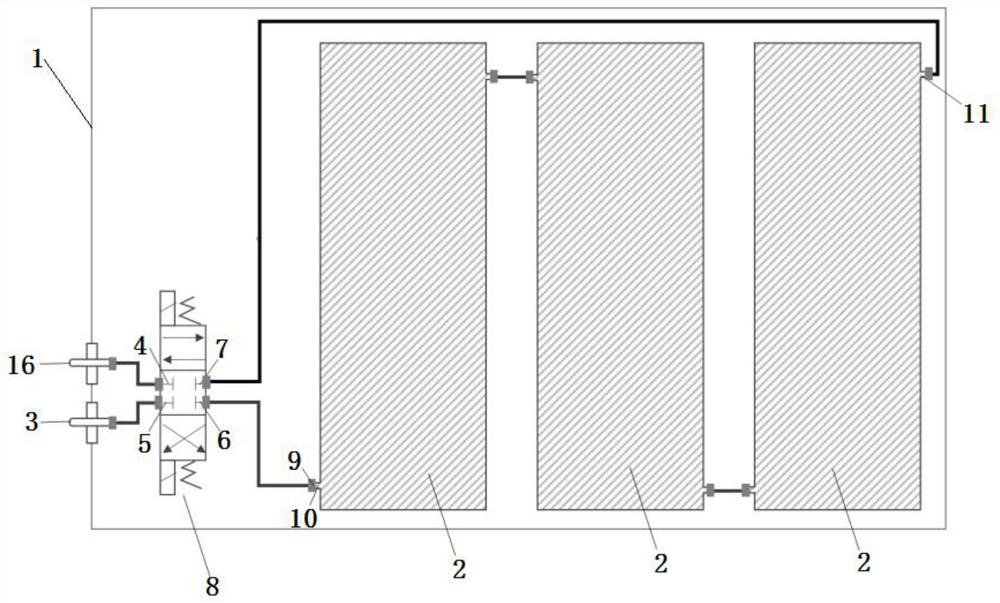

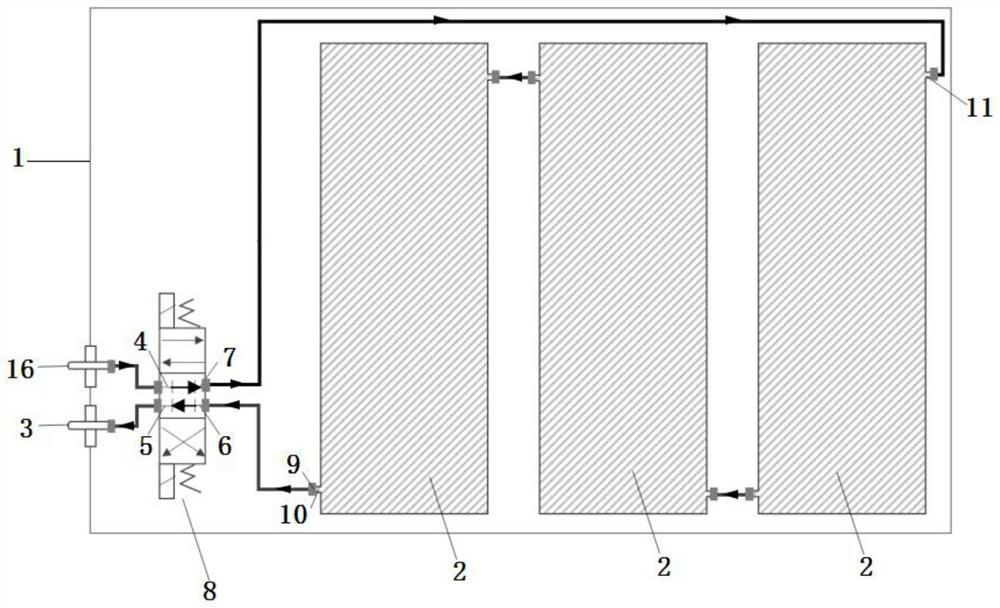

[0022] Such as figure 1 The cooling liquid shown in -4 flows to the controllable battery pack, including the battery pack housing 1 and the liquid cooling plate 2 arranged in the battery pack housing 1, and the battery pack housing 1 is provided with a battery pack water inlet 16 and a battery pack Water outlet 3.

[0023] The battery pack housing 1 is also provided with a three-position four-way electromagnetic steering valve 8 that communicates with the liquid cooling plate 2 through pipelines and can change the flow direction of the cooling liquid in the liquid cooling plate 2 , including a water inlet 16 connected to the battery pack through a pipe. The water inlet 4 of the device connected by the road, the water outlet 5 of the device connected with the battery pack water outlet 3 through the pipeline, the first device pipe inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com