A Winding Wiring and Wiring Structure for Single-phase Asynchronous Motor

A single-phase asynchronous, wiring structure technology, applied to the shape/style/structure of asynchronous induction motors, electric components, winding conductors, etc., can solve the problems of difficult interphase insulation treatment, poor effect, difficult automatic mass production, etc., to achieve The effect of exempting from insulating bandaging and fixing binding processes, easy implementation, wide application and promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

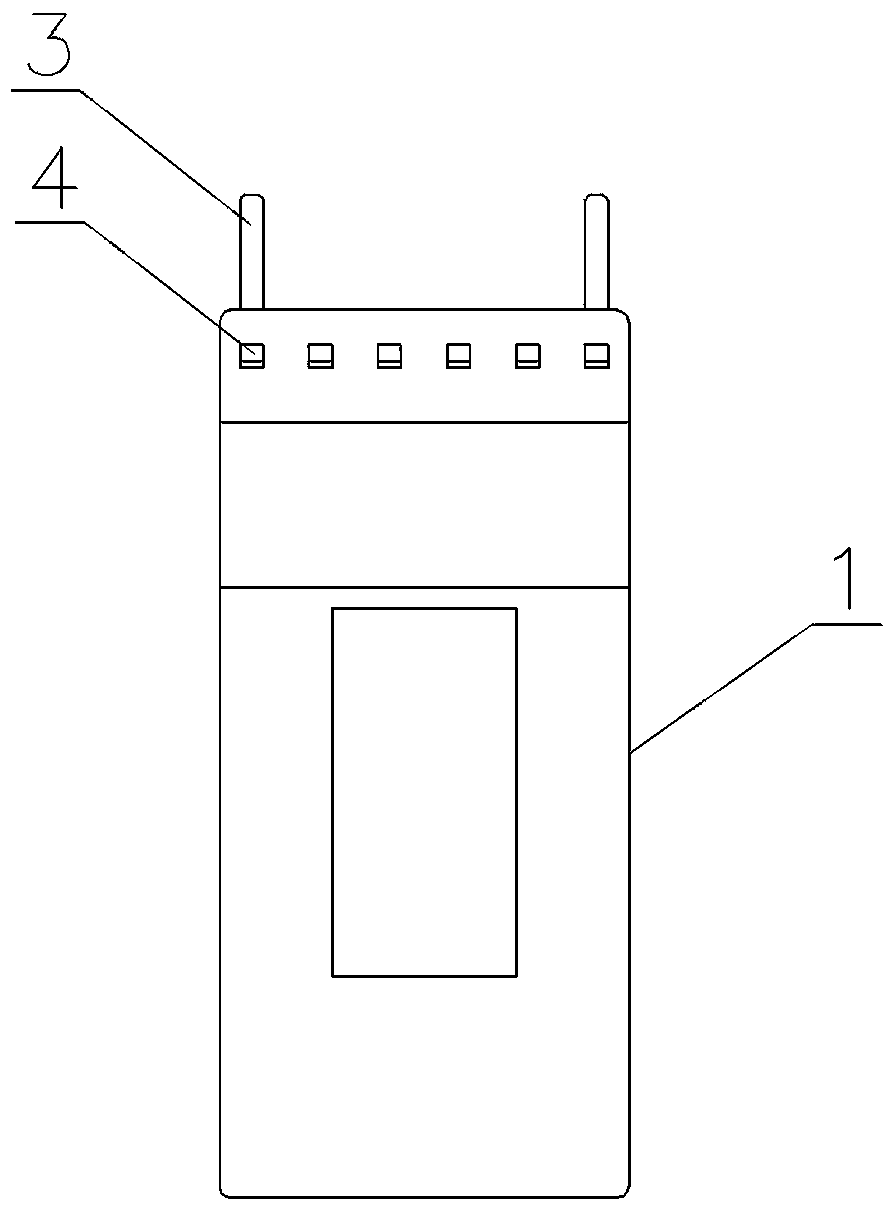

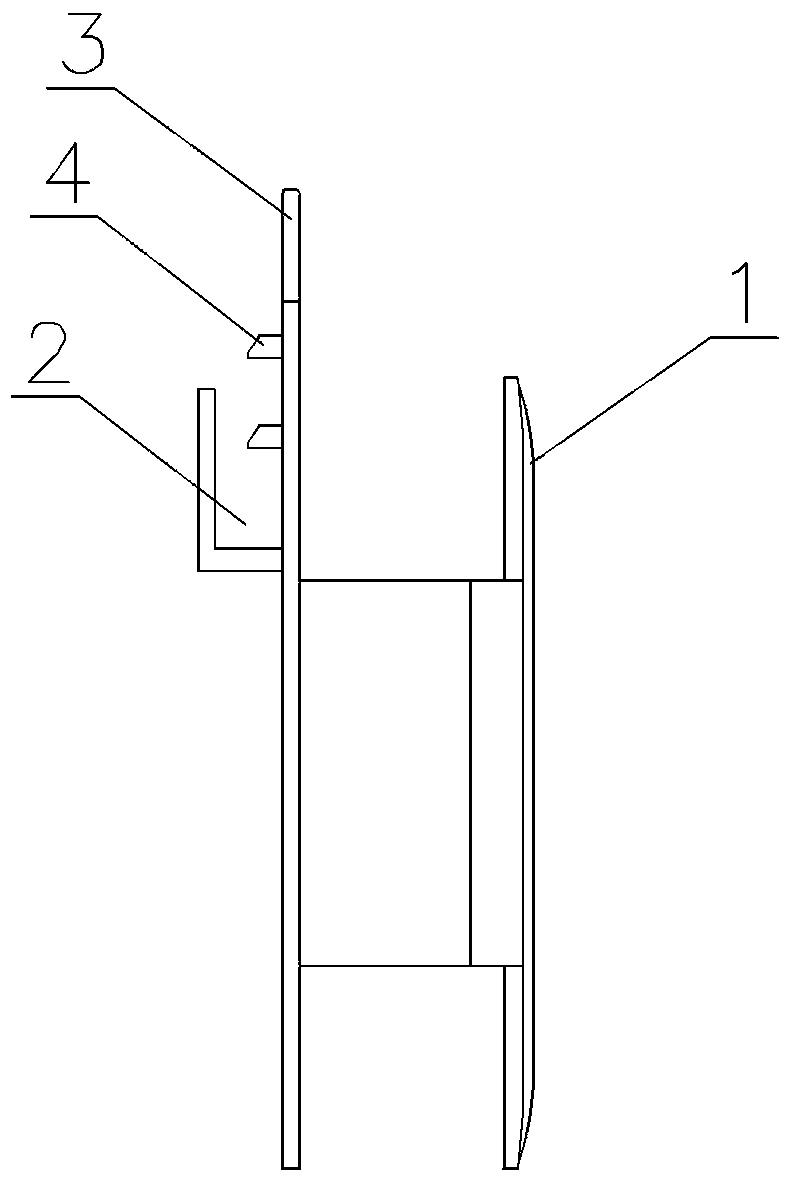

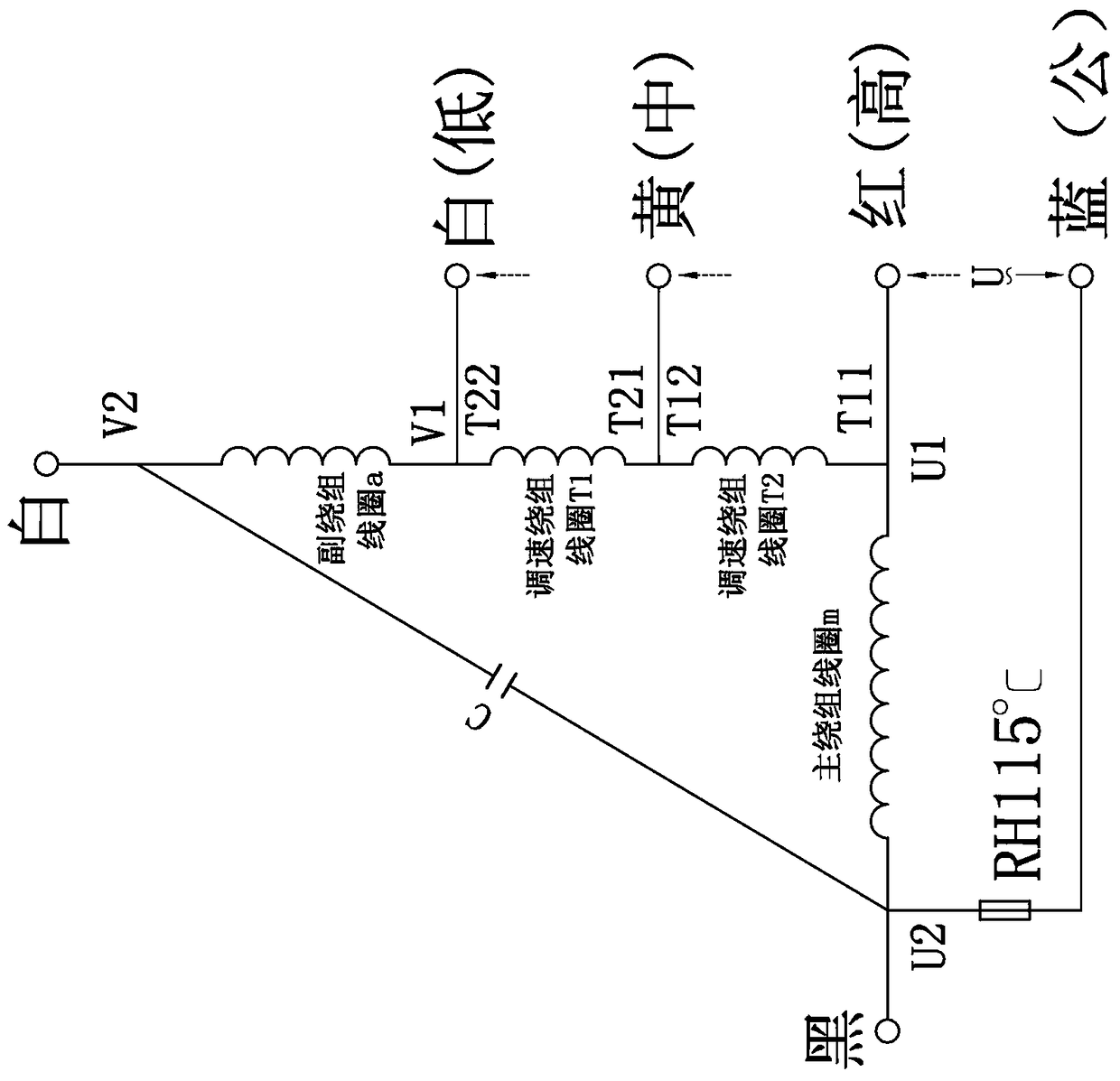

[0025] attached Figure 1-3 As shown, a winding wiring and wiring structure for a single-phase asynchronous motor includes electromagnetic coils, bridge wires, connecting wires and lead wires. The bridge line refers to the connection line between the electromagnetic coils of the same phase and different poles. The connection line refers to the connection line between the main winding, the auxiliary winding and the speed regulating winding. The lead wire refers to the connecting wire of the electromagnetic coil to the external power supply or components. The electromagnetic coil includes the main winding coil m, the secondary winding coil a and the speed regulating winding coil T 1 ~T 2 . Main winding coil m, secondary winding coil a and speed regulating winding coil T 1 ~T 2 The composition and structure are the same, and the main winding coil m is taken as an exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com