Device and method for catalytically cracked gasoline and diesel oil coupling desulfurization

A catalytic cracking gasoline and catalytic cracking diesel technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of increasing equipment investment and processing steps, and achieves the reduction of investment and operating costs, easy process control, The effect of mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] FCC gasoline contains the following components and their mass content: aromatics 14.5%, olefins 31.5%, saturated hydrocarbons 54%, sulfide 296ppm; FCC gasoline has an initial boiling point of 29°C and an end boiling point of 198°C; FCC diesel The initial boiling point is 199°C, the final boiling point is 384°C, and the sulfide is 3250ppm.

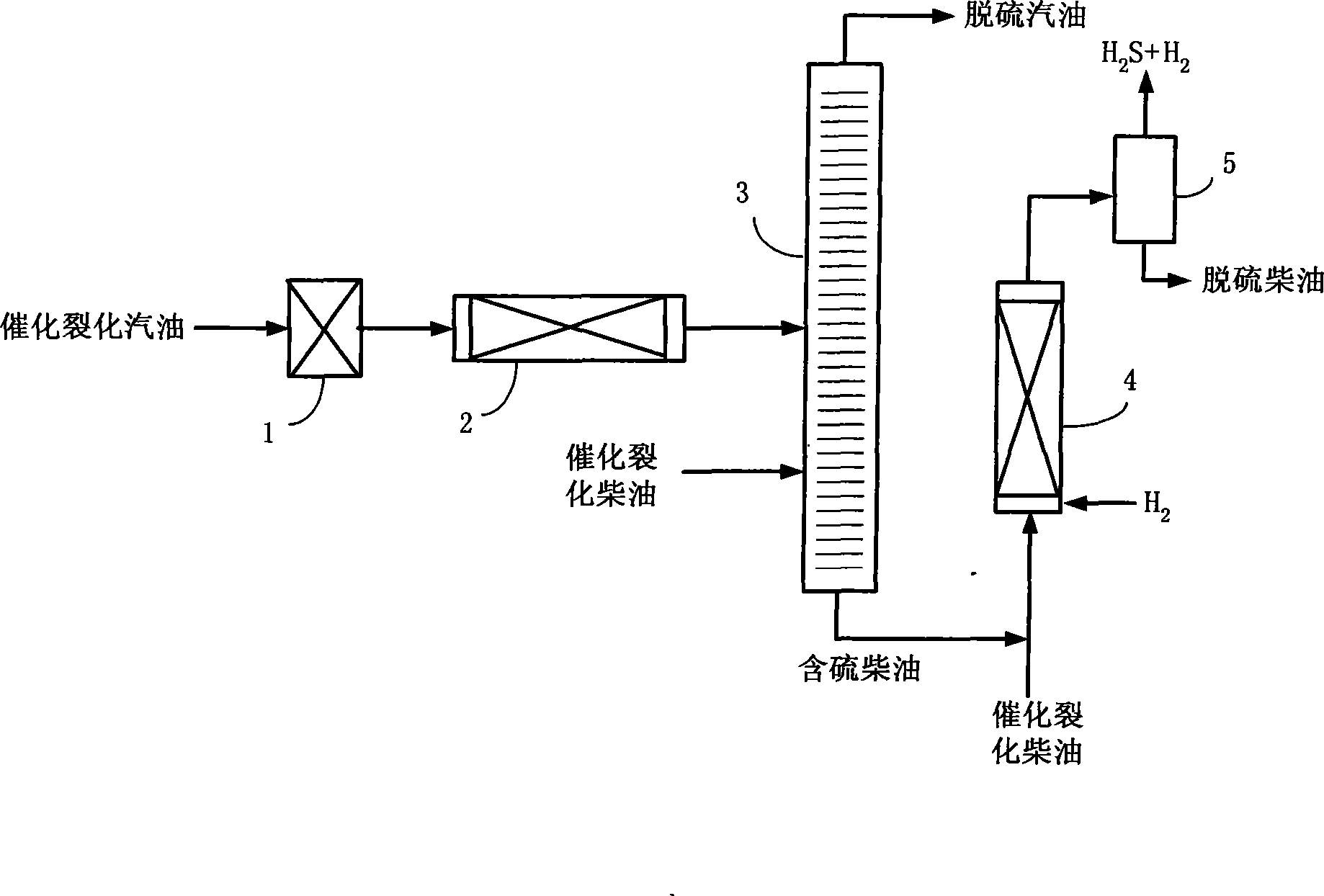

[0029] Using the device shown in Figure 1, the catalytic cracking gasoline is 50h -1 The space velocity is added to the catalytic cracking gasoline pretreater 1 equipped with LSI-600 ion exchange resin, the operating pressure of the pretreater is 0.7MPa, and the temperature is 80°C; Alkylation reactor 2, the reactor is filled with solid phosphoric acid and USY, the mass ratio of the two catalysts is 1:1, the reaction temperature is 150°C, the pressure is 3.0MP, and the space velocity is 5h -1 Add the effluent of the alkylation reactor from the middle of the sulfur transfer fractionation tower 3, the fractionation tower has 20 theore...

Embodiment 2

[0031] FCC gasoline contains the following components and their mass content: aromatics 20.6%, olefins 43.2%, saturated hydrocarbons 36.2%, sulfide 1980ppm; FCC gasoline has an initial boiling point of 33°C and an end boiling point of 183°C; the initial boiling point of diesel oil The point is 190°C, the final boiling point is 355°C, and the sulfide is 2800ppm.

[0032] Using the device shown in Figure 1, the catalytic cracking gasoline is 30h -1The space velocity is added to the catalytic cracking gasoline pretreater 1 equipped with NKC-9 ion exchange resin, the operating pressure of the pretreater is 0.1MPa, and the temperature is 20°C; the stream flowing out from the pretreatment is introduced into thiophene sulfur Alkylation reactor 2, the reactor is filled with NKC-9 sulfonic acid resin catalyst, the reaction temperature is 80°C, the pressure is 0.15MPa, and the space velocity is 20h -1 Add the effluent of the alkylation reactor from the middle of the sulfur transfer fra...

Embodiment 3

[0034] FCC gasoline contains the following components and their mass content: 45% aromatics, 18% olefins, 37% saturated hydrocarbons, and 950ppm sulfides; the initial boiling point of catalytic cracking gasoline is 46°C, and the final boiling point is 206°C; The point is 210°C, the final boiling point is 397°C, and the sulfide is 4150ppm.

[0035] Using the device shown in Figure 1, the catalytic cracked gasoline was used for 5h -1 The space velocity is added to the catalytic cracking gasoline pretreater 1 equipped with CT-175 ion exchange resin, the operating pressure of the pretreater is 0.2MPa, and the temperature is 40°C; Basement reactor 2, the reactor is filled with β molecular sieve and ZSM-5 molecular sieve, the mass ratio of the two catalysts is 2:1, the reaction temperature is 120°C, the pressure is 1.0MP, and the space velocity is 12h -1 Add the effluent of the alkylation reactor from the middle of the sulfur transfer fractionation tower 3, the fractionation tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com