Biochemical treatment process for high salinity wastewater

A high-salt wastewater, biochemical treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increased investment, waste of water resources, huge treatment facilities, etc. Specialized flora and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

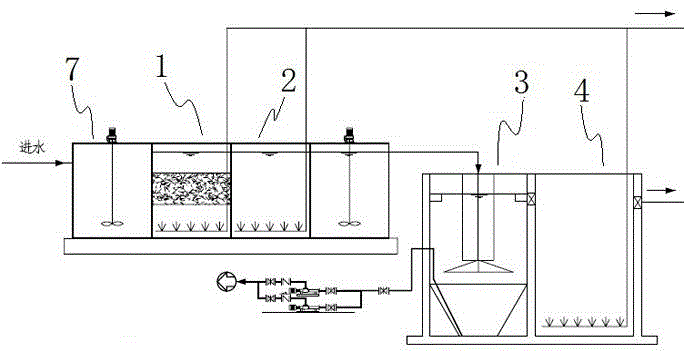

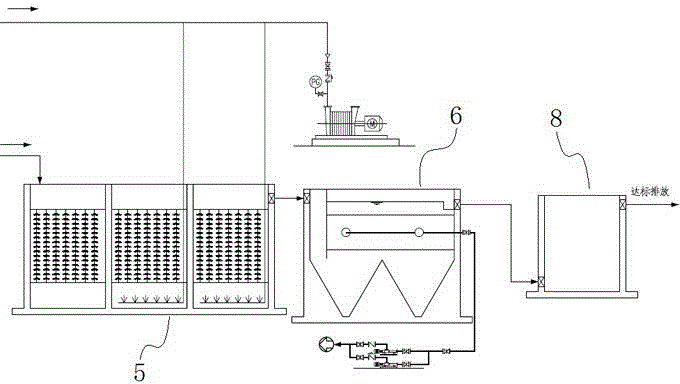

Image

Examples

Embodiment Construction

[0032] The tail water quality of the treatment facility of a biochemical company is: pH: 7.0-7.5, COD: 4500-4800 mg / L, salt content 3.5-6.0%, BOD: about 600 mg / L, phenol about 100 mg / L .

[0033] First, isolate and screen the salt-tolerant bacteria directly from the bottom mud of the biochemical plant outlet that produces high-salt wastewater, and use the filler in the reactor to successfully form the film of the salt-tolerant bacteria. Among them, the salt-tolerant bacteria is Erysipelothrix cvcc 1188 or Lactobacillus CICC20328 13830 .

[0034] Then configure the simulated wastewater. The components of the simulated wastewater are glucose, sodium phosphate dodecahydrate, urea, water and sodium chloride; 1.2376g of glucose, 0.159g of sodium phosphate dodecahydrate, and 0.062g of urea are added to each liter of water, and then Sodium chloride, so that the salinity of the simulated wastewater is 3%~5%;

[0035] Afterwards, the salt-tolerant bacteria are domesticated; the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com