Concrete and preparation method thereof

A concrete and mixture technology, applied in the field of concrete, to achieve good mechanical properties, improve cold resistance, and not easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

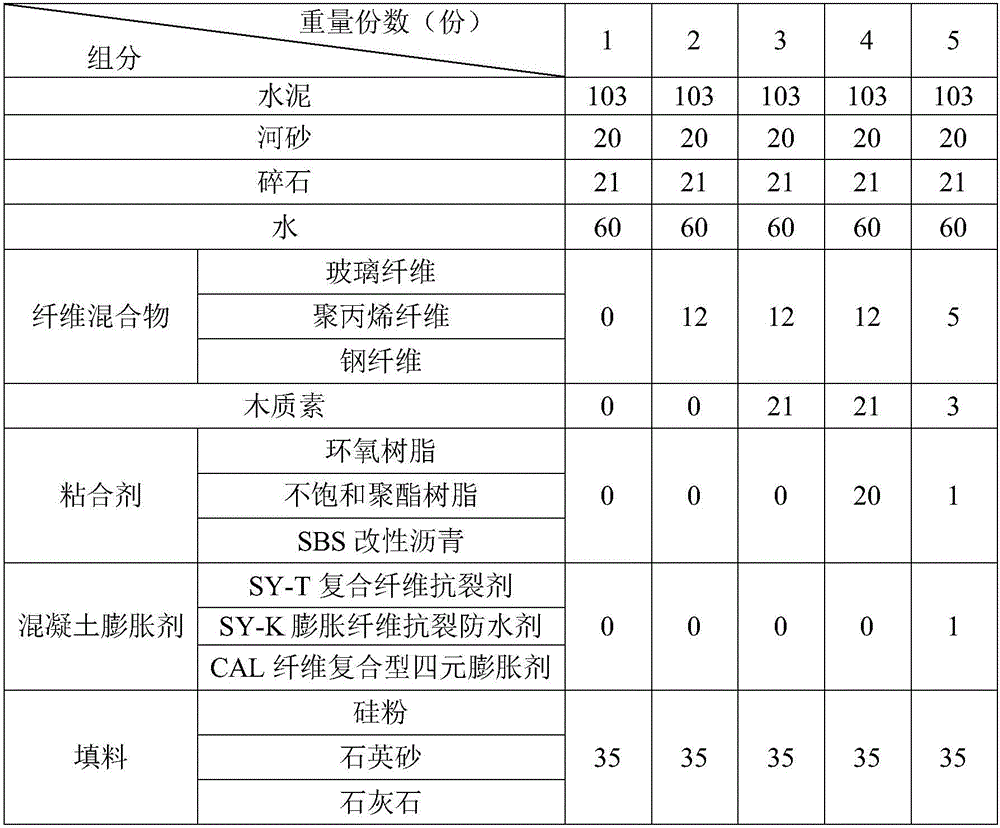

[0066] Embodiment 1: Concrete, components and corresponding parts by weight thereof are shown in Table 1, and are prepared through the following steps:

[0067] S1, uniformly mixing cement, river sand with a fineness modulus of 1.8-2.2, and gravel with a size of 20-25 mm to obtain the first mixture;

[0068] S2, the fiber mixture composed of glass fiber, polypropylene fiber and steel fiber with a ratio of parts by weight of 2.5:1.5:1, and lignin and silicon powder with a ratio of parts by weight of 2-3:3-3.5:1 , quartz sand, and limestone to form a second mixture, which is uniformly mixed with the first mixture obtained in S1 to form a third mixture, wherein the aspect ratio of the fiber mixture is 25-60, and the particle size of the filler is 200-250 mesh; S3, the adhesive composed of epoxy resin, unsaturated polyester resin, SBS modified asphalt with a ratio of parts by weight of 6:2.5:1, and a ratio of parts by weight of 1.52:1 : 1.65 SY-T composite fiber anti-cracking age...

Embodiment 2-3

[0069] Example 2-3: Concrete, the difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1.

[0070] Components and their corresponding parts by weight in Table 1 Embodiment 1-3

[0071]

Embodiment 4

[0072] Embodiment 4: concrete, the difference from embodiment 1 is that the fiber mixture is a mixture of glass fiber and polypropylene fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com