High-toughness inspection well concrete and method for preparing same

An inspection well and concrete technology, applied in the field of concrete, can solve the problems of toughness, low strength, poor impact toughness, large drying shrinkage, etc., and achieve the effects of good durability, strong impact resistance and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

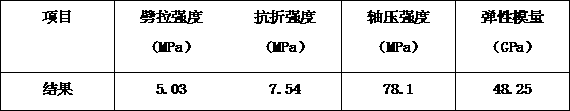

Examples

Embodiment Construction

[0014] High-toughness inspection well concrete, including the following components by weight: 380 parts of ordinary Portland cement, 85 parts of fly ash, 28 parts of calcined red mud, 66 parts of slag powder, and isopropyl distearoyl aluminum 3 parts of acid ester, 25 parts of styrene-acrylic emulsion, 110 parts of straw ash, 36 parts of modified rubber powder, 1120 parts of limestone gravel, 540 parts of river sand, 150 parts of water, 6 parts of naphthalene-based superplasticizer.

[0015] Wherein, the particle size of the limestone gravel is 10mm; the particle size of the river sand is 5mm, and the mud content is less than 2%.

[0016] The modified rubber powder is prepared by the following method: soak the rubber powder in NaOH saturated solution for 25 minutes, wash and filter, then dry, add 3% coupling agent KH-560, 5% Polyvinyl alcohol and 0.3% methyl hydroxyethyl cellulose ether can be dried after ball milling for 2 hours.

[0017] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com