Artificial reef preparation with metallurgy slag as principal raw material

A technology for artificial reefs and main raw materials, applied in the field of artificial reefs and artificial reef preparation, can solve the problems of limited utilization, poor durability, low center of gravity, etc., and achieve the effects of reducing preparation costs, improving living environment, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

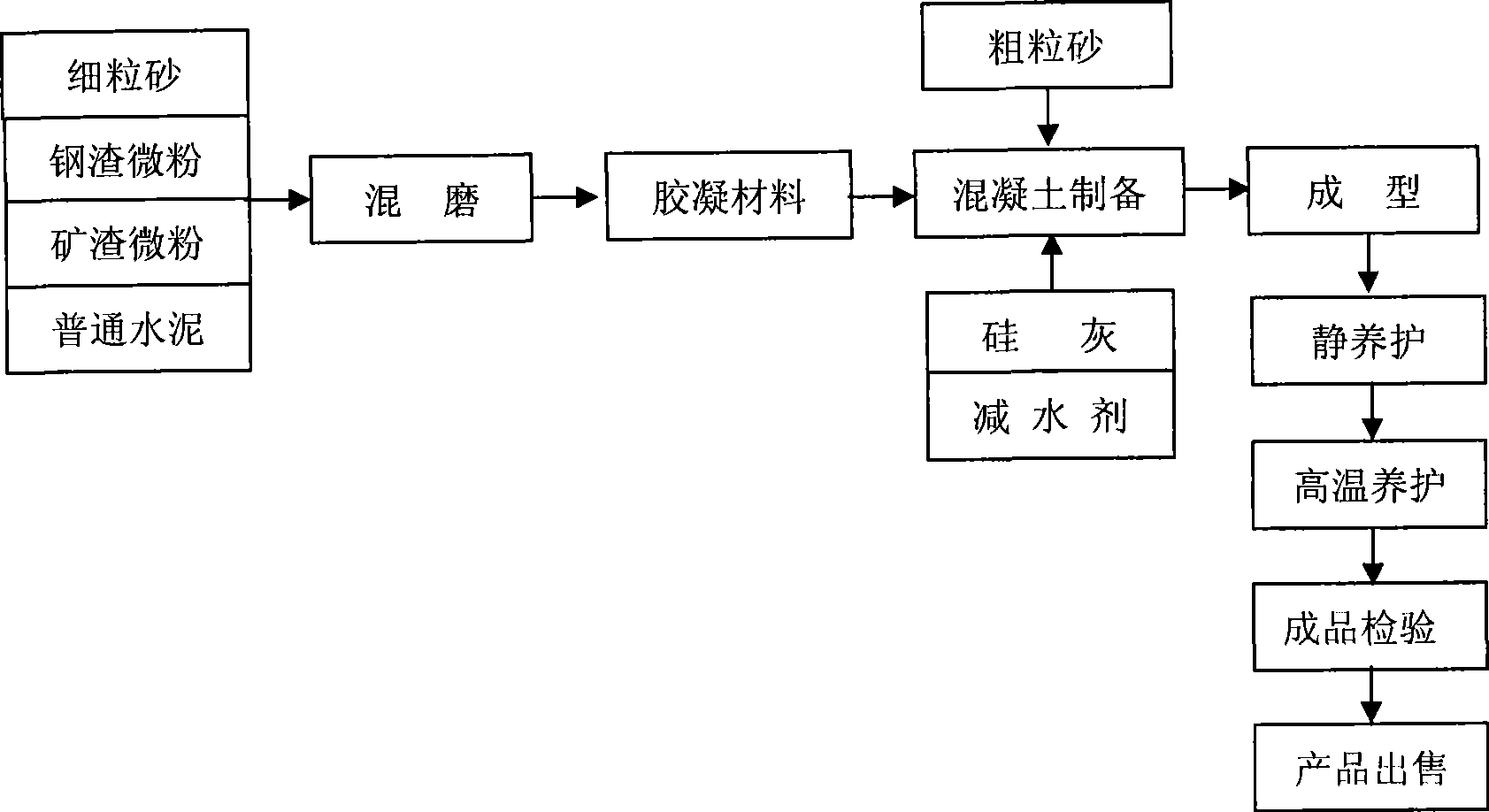

[0022] The invention relates to a method for preparing an artificial fish reef with metallurgical slag as the main raw material, which realizes the combination of steps figure 1 Described as follows:

[0023] (1) Firstly, the sea sand or river sand is screened and classified, the sand with a particle size greater than 5 mm is used for coarse aggregate, and the sand with a particle size smaller than 5 mm is used as a raw material for the preparation of cementitious materials.

[0024] (2) Mix and grind steel slag powder, slag powder, fine-grained sand and cement clinker in a ratio of 30%:25%:10%:35%, and the specific surface area of the obtained cementitious material is greater than 350m 2 / kg, and then mix the cementitious material with coarse-grained sand, gravel, silica fume, water reducer, etc., and the proportion of cementitious material, sand and stone in concrete is 40%:40%:20%.

[0025] (3) Depending on the shape of the mold, the shape of the obtained artificial reef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com