High-performance machine-made sand marine concrete and preparation method thereof

A high-performance concrete technology, applied in the field of building materials, can solve the problems that affect the strength and durability of concrete, threaten the safety of infrastructure facilities, and the particle gradation is not as good as river sand, so as to achieve stable and controllable quality and meet the design technology Requirements, the effect of good quality concrete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of high-performance machine-made sand marine concrete comprises the following steps:

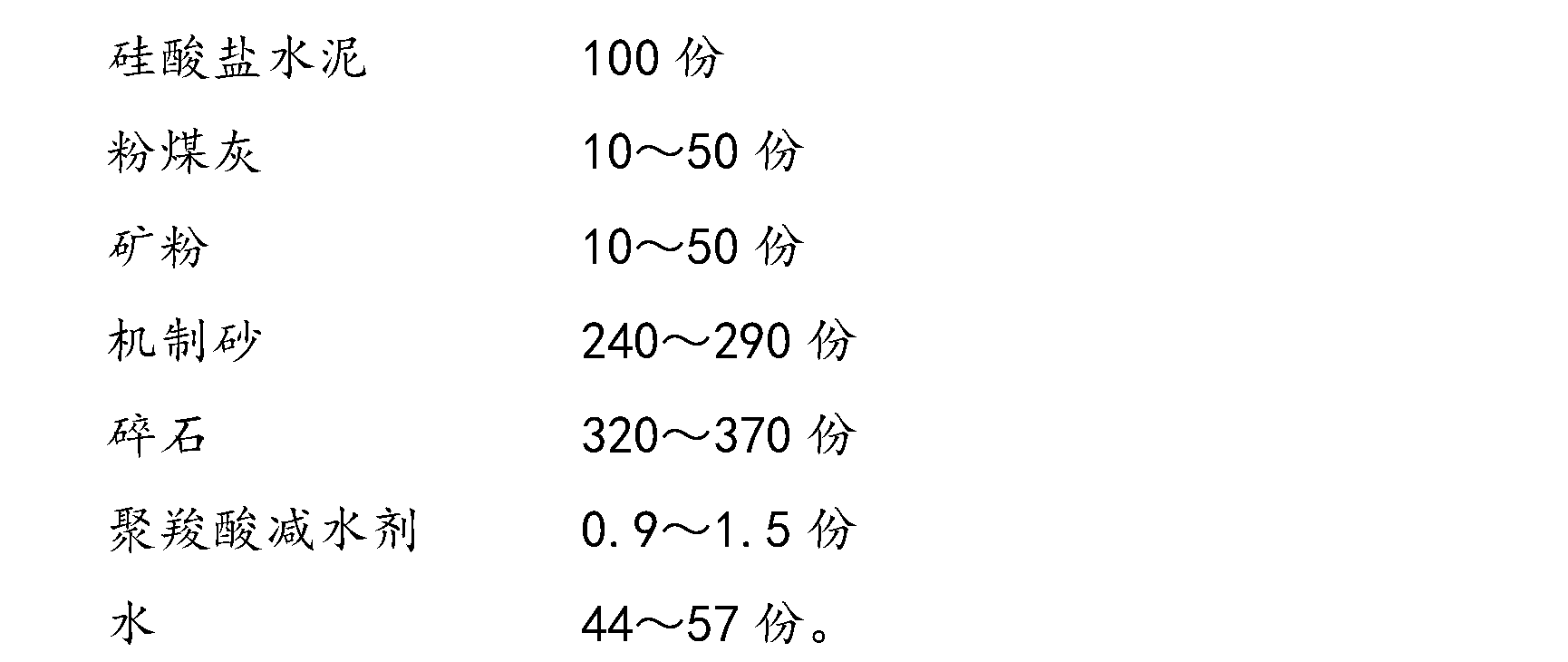

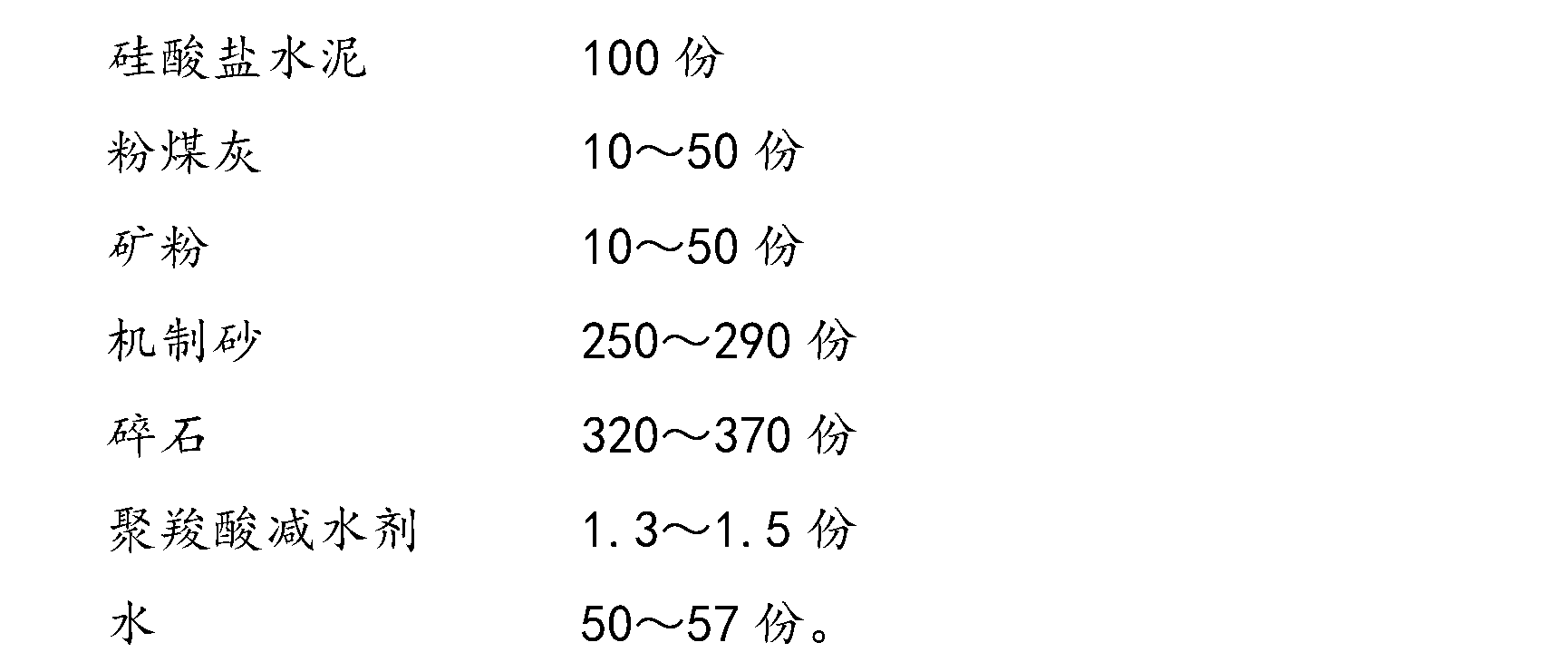

[0030] 1) According to the weight ratio of raw material components, weigh Portland cement, fly ash, mineral powder, machine-made sand, crushed stone, polycarboxylate superplasticizer and water in corresponding parts by weight, and set aside. The raw materials are equipped as follows:

[0031] Portland cement is P.Ⅱ type Portland cement produced by Hubei Yadong Cement Co., Ltd., with a strength grade of 42.5 and a specific surface area of 385 m 2 / kg, water requirement for standard thickening is 27.4%, initial setting time is 136min, final setting time is 195min, 3d compressive strength and flexural strength are 31.0MPa and 5.3MPa, 28d compressive strength and flexural strength are 58.4MPa and 9.4 MPa;

[0032] The fly ash is Class II fly ash produced by Wuhan Yangluo Power Plant, with a fineness of 7.1% and a loss on ignition of 3.4%;

[0033] The mineral p...

Embodiment 1~3

[0044] Examples 1-3 are marine concrete prepared by the above-mentioned preparation method according to three different weight ratios, and a river sand concrete is added as a comparison example. The weight ratio of each raw material component is shown in Table 2:

[0045] Table 2

[0046]

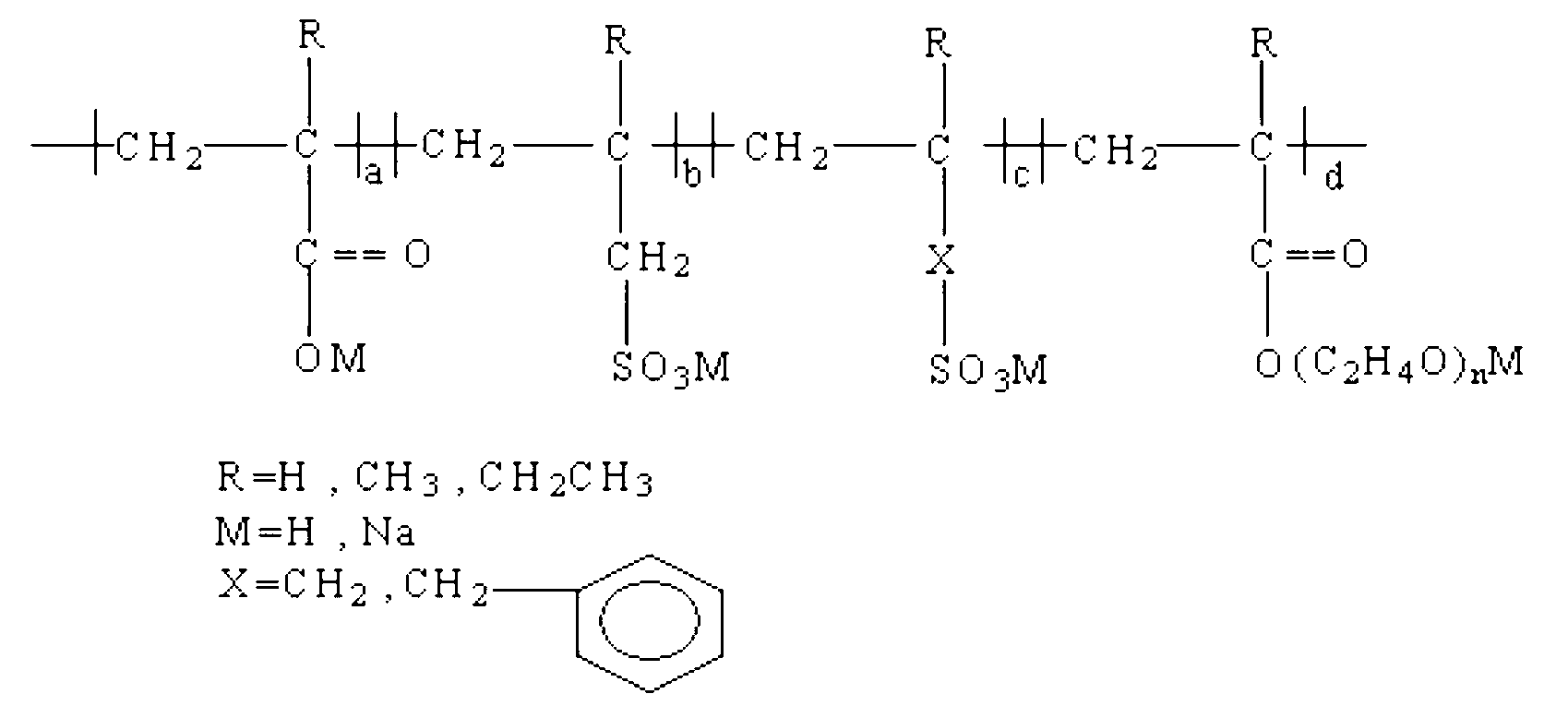

[0047] Among them, the water reducing agent used in Example 1 is the LN type polycarboxylate water reducing agent produced by Wuhan Gangwan, and the water reducing rate is 35.6%; the water reducing agent used in Example 2 and Comparative Examples 1 to 3 is Haide The SP water reducing agent produced by Shun has a water reducing rate of 33.1%; the water reducing agent used in Example 3 is the PC water reducing agent produced by Jiangsu Aulite, and the water reducing rate is 32.6%.

[0048] The main performance parameters of the concrete that each embodiment and comparative examples make in table 2 are as shown in table 3:

[0049] table 3

[0050]

Embodiment 4

[0055] Using the above-mentioned preparation method of machine-made sand marine concrete, according to the weight ratio of raw material components, P.Ⅱ42.5 type Portland cement is 288kg, class II fly ash is 96kg, S95 grade mineral powder is 96kg, machine-made sand is 761kg, and crushed stone is 1009kg. , 3.36kg of water reducing agent and 148kg of mixing water to make machine-made sand marine concrete. Among them, the water reducer used in this example is the SP type polycarboxylate water reducer produced by Shanghai Deshun, and the water reducing rate is 33.1%; the machine-made sand used in this example is the II gradation zone produced by Ninghai Chuangli Machine-made sand, fineness modulus 2.9, stone powder content 8%, MB value 0.8.

[0056] According to the test, the machine-made sand marine concrete produced in this example has good workability, mechanics and durability, the slump reaches 185mm, the 4d compressive strength is 53.3MPa, and the 28d compressive strength is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Coagulation time | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com