Sintered NdFeB permanent magnet with high working temperature and high corrosion resistance

A working temperature, permanent magnet technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of magnet remanence or magnetic energy product decline, magnet corrosion performance has not been well improved and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

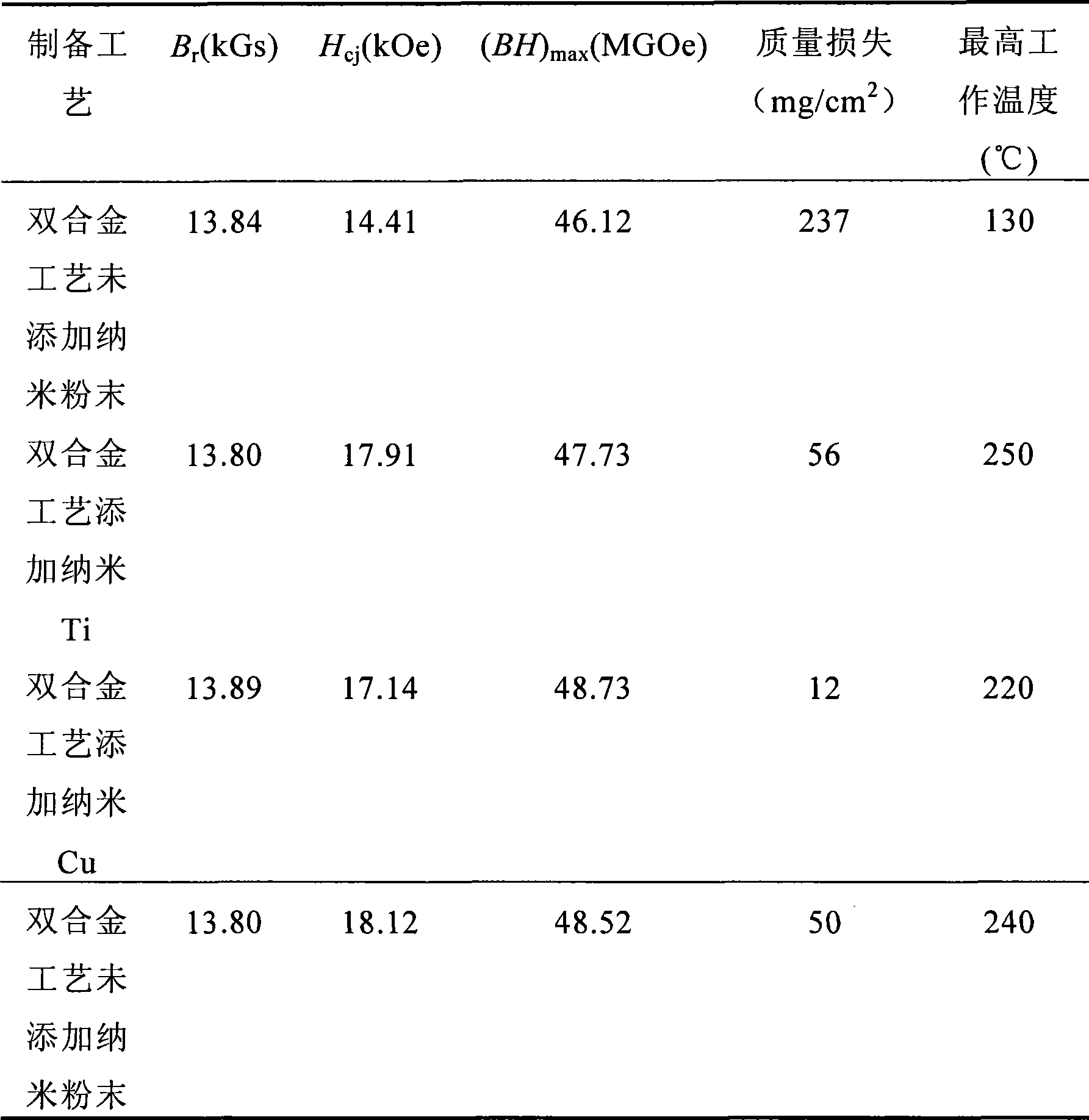

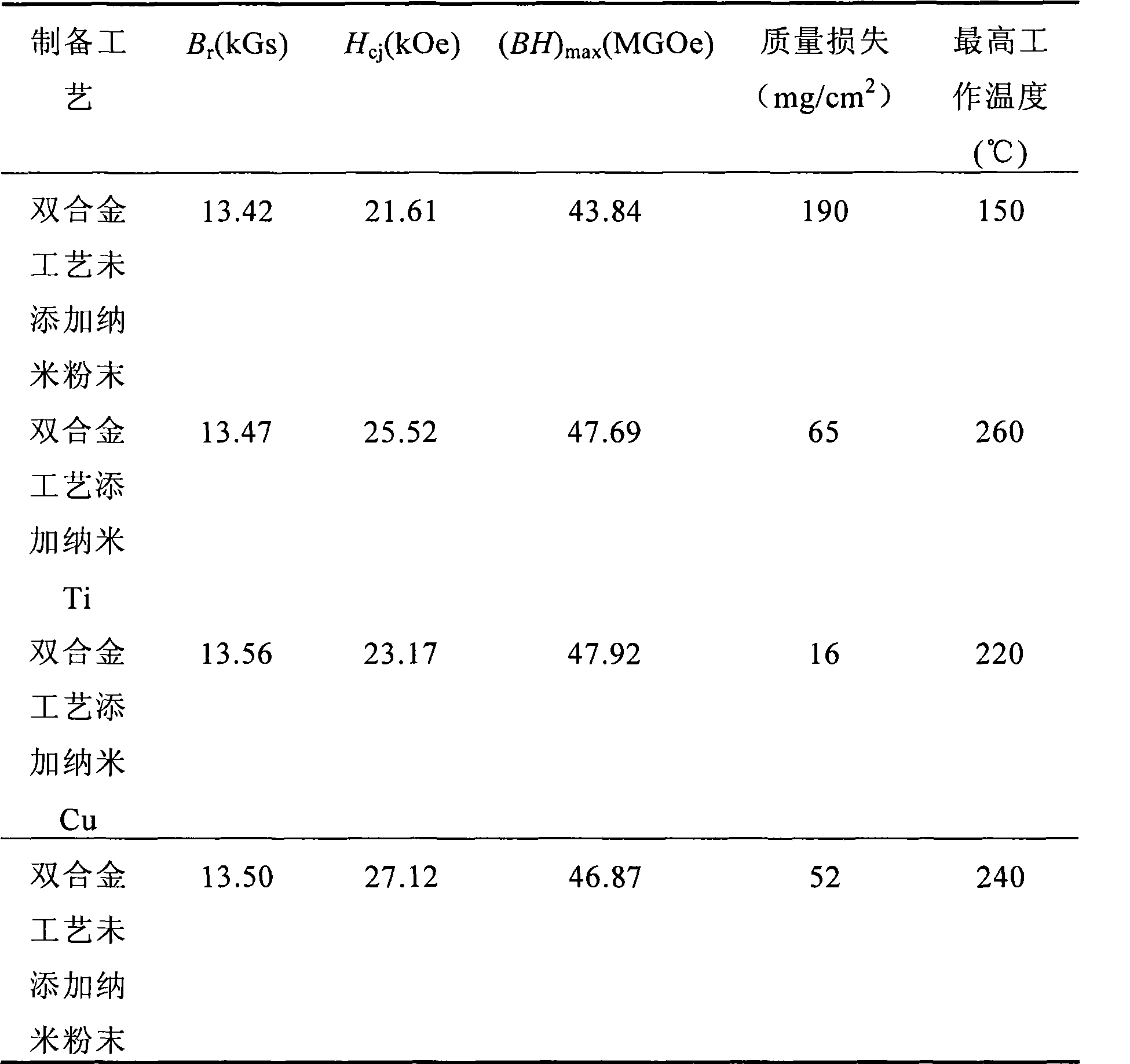

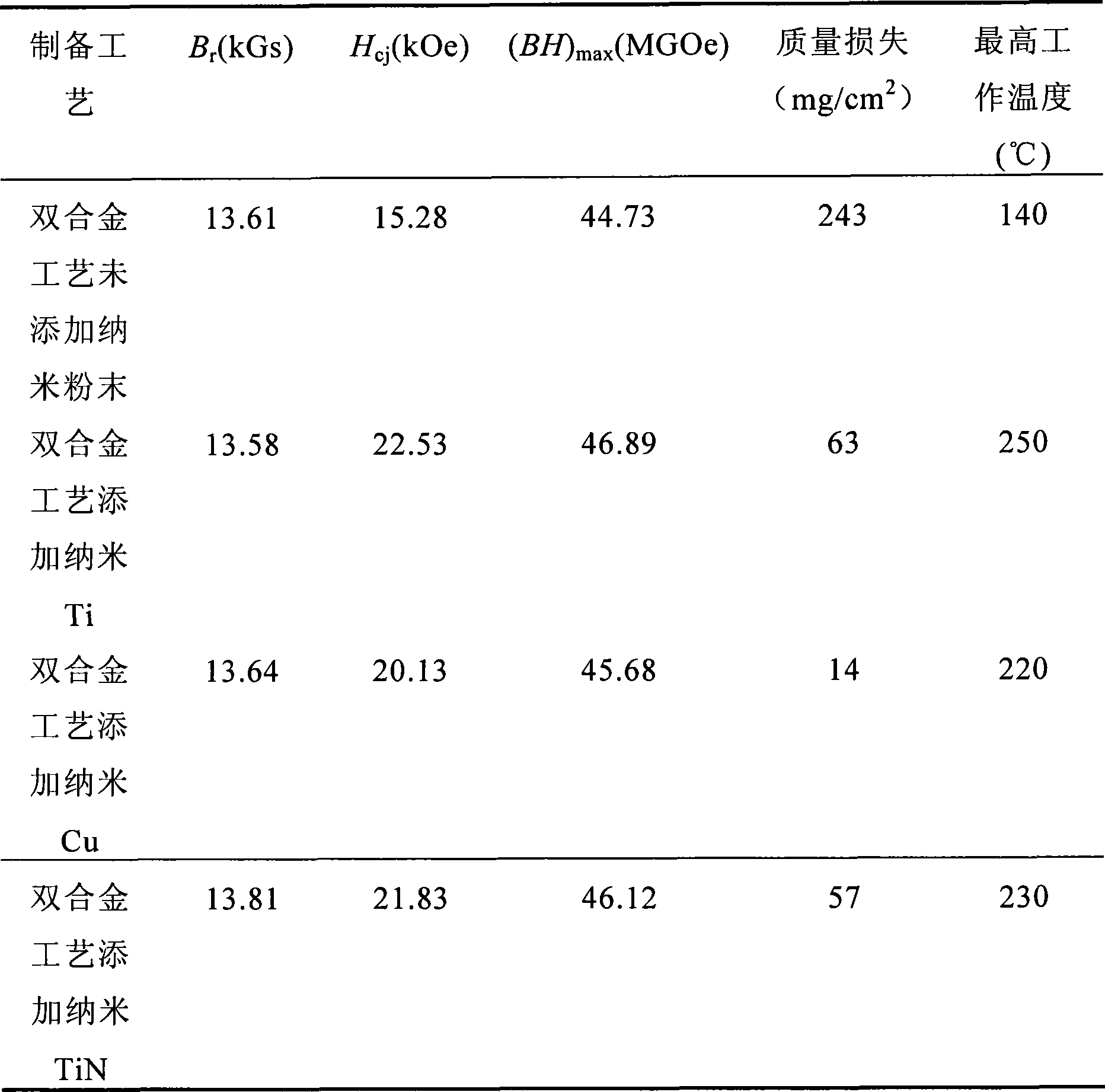

Embodiment 1a

[0112] 1) Prepare the main phase alloy and the grain boundary phase alloy separately. The main phase alloy adopts the quick-setting sheet technology, the surface speed of the copper roller is 1.2m / s, and the composition is Nd 13.12 Fe 80.69 B 5.73 (Dy 0.22 al 0.24 )(at%), the grain boundary phase alloy is prepared into a rapid quenching zone with a rapid quenching speed of 18m / s, and the composition is Nd 17.2 Fe 75.58 B 6.38 Dy 0.64 Ga 0.2 (at%).

[0113] 2) Powder the main phase alloy and the grain boundary phase alloy respectively. Coarse crushing by jaw crusher, intermediate crushing by secondary crusher, and then jet milling under nitrogen protection, the main phase alloy is made into powder with an average particle diameter of 3 μm, and the grain boundary phase alloy is made into a powder with an average particle diameter of 1 μm of powder.

[0114] 3) In the grain boundary phase alloy powder, respectively add nano-titanium (average particle diameter is 40nm) ...

Embodiment 1b

[0119] The method of embodiment 1b is the same as that of embodiment 1a, except that nano-copper powder is used in step 3). The properties obtained are shown in Comparative Example 1.

Embodiment 1c

[0121] The method of embodiment 1c is the same as that of embodiment 1a, except that nano-titanium nitride powder is used in step 3). The properties obtained are shown in Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com