Superfine electroform technique of supercutical fluid, and equipment

A supercritical fluid and micro-technology, applied in the field of electrochemistry, can solve problems such as uneven deposition of microstructure parts, surface area tumors, etc., achieve uniform electric field distribution, and improve the effect of deposition conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

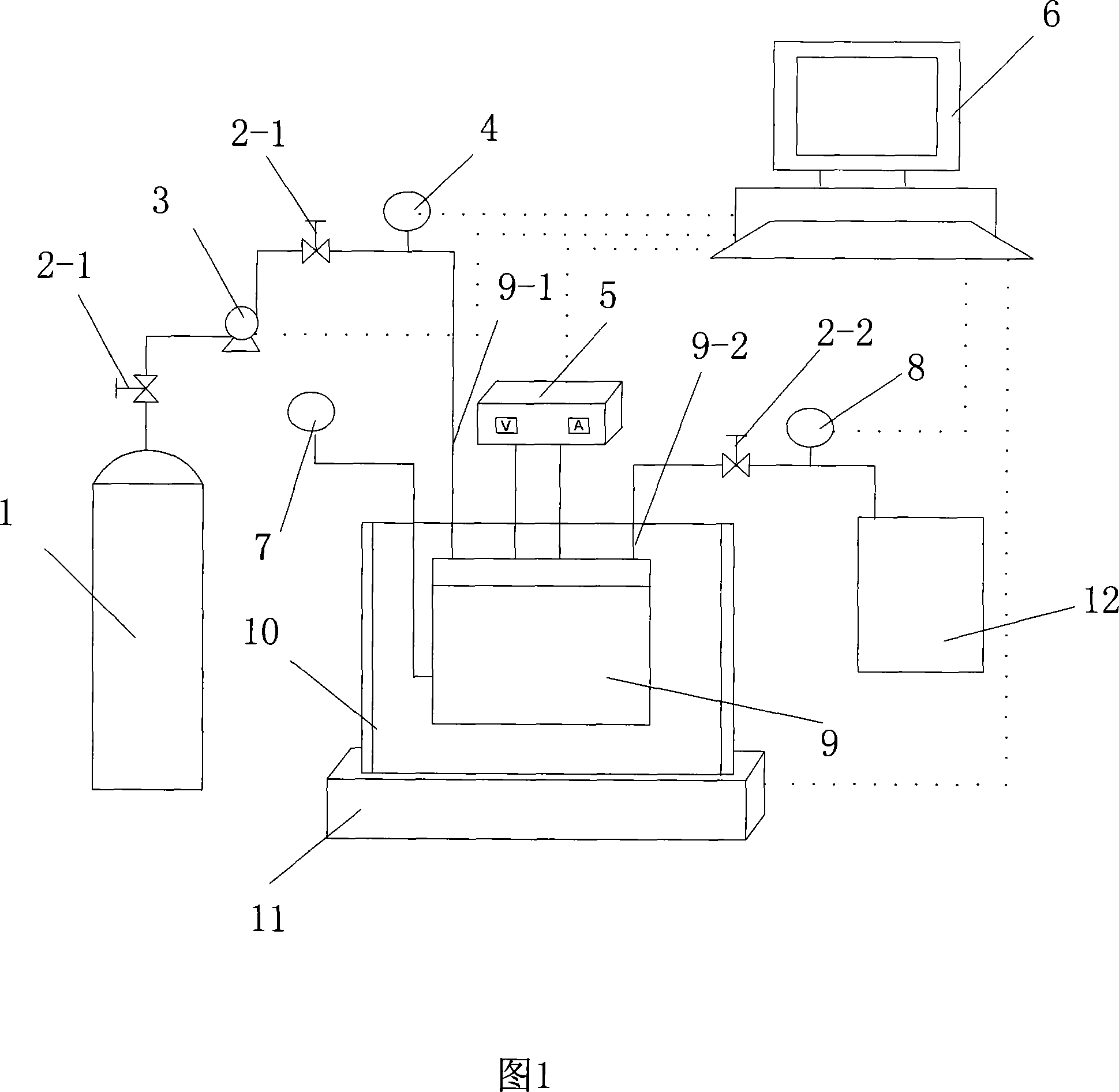

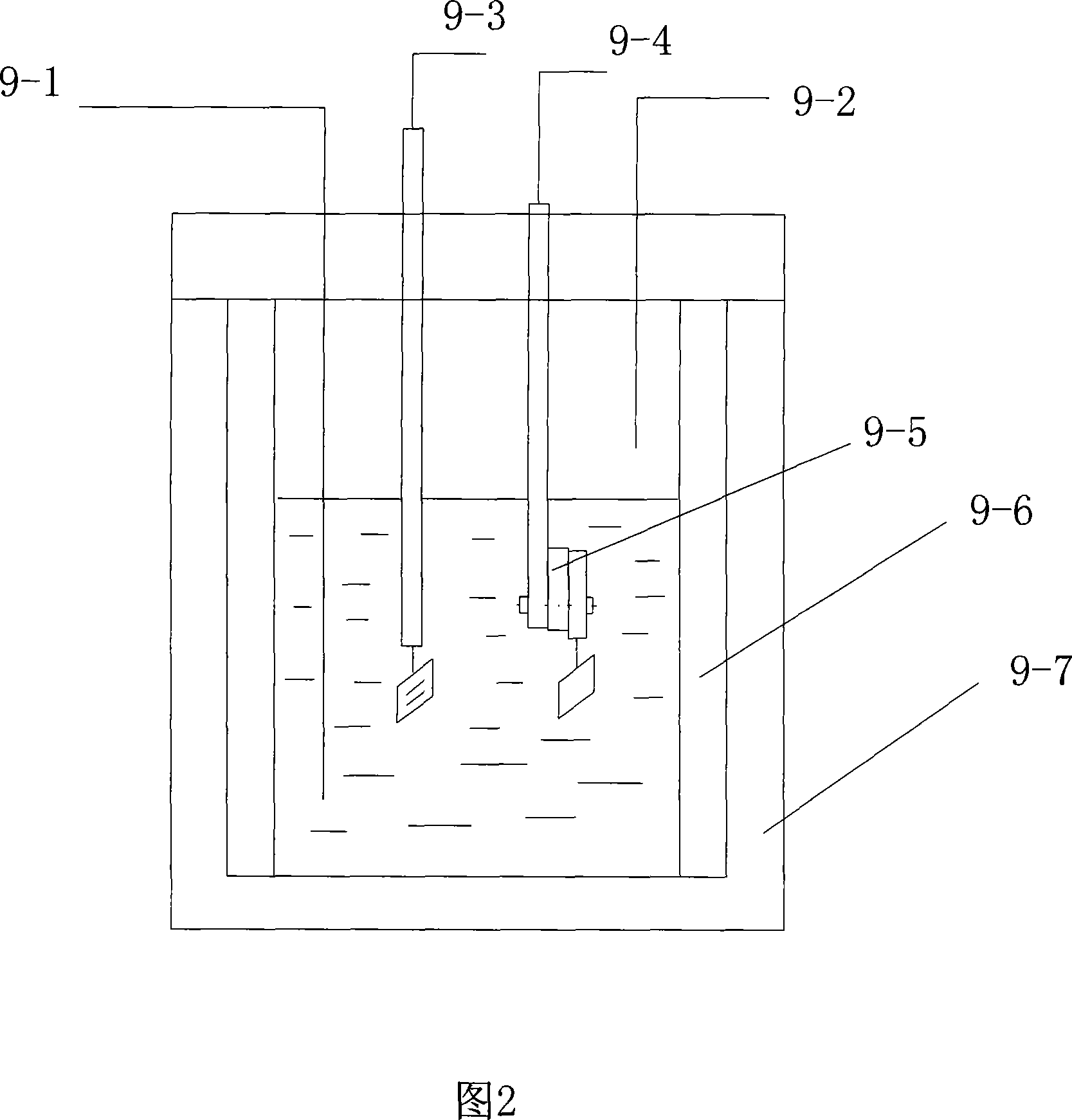

[0020] The supercritical fluid micro-electroforming device of the present invention is shown in FIG. 1 . The device includes CO 2 Gas cylinder 1 , high pressure pump 3 , DC power supply 5 , control unit 6 , fine deposition unit 9 , constant temperature bath 10 , magnetic stirrer 11 and recovery device 12 . Wherein the fine deposition unit 9 is as shown in Figure 2, and it comprises a reactor 9-7 and lining 9-6 thereof, and this reactor 9-7 can adopt stainless steel or high-strength structural steel to process, and reactor lining 9 -6 is a corrosion-resistant tetrafluoroethylene material. The fine deposition unit 9 also includes an air inlet 9-1 and a liquid outlet 9-2, a cathode 9-3 and an anode 9-4, the cathode 9-3 is integrated with the photolithography template, and the anode is a metal plate, and is connected with the metal solution The metal contained is the same, which can be pure copper plate or pure nickel plate, which not only plays the role of conductivity, but als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com