A precursor with iron-rich surface and manganese-rich core and method for preparing carbon-coated lithium manganese iron phosphate material using the precursor as raw material

A technology of lithium manganese iron phosphate and carbon coating, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of underutilized precursor raw material preparation process, difficulty in controlling reaction conditions, product purity, and high quality control requirements for raw materials. , to achieve the effect of easy regulation of material composition distribution, improvement of electrical conductivity and electrochemical performance, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

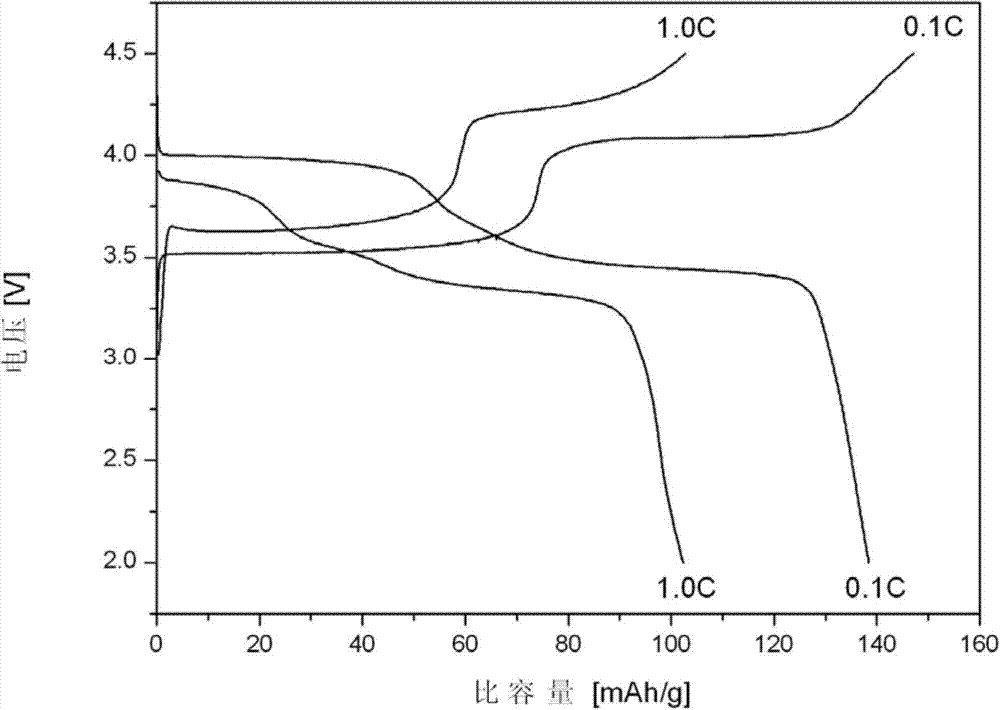

Embodiment 1

[0040] Carbon-coated lithium manganese iron phosphate materials were prepared based on precursors rich in iron on the surface and rich in manganese in the core. In this method, the precursor is not separated after preparation, and other raw materials are directly added to it for reaction to prepare a carbon-coated lithium manganese iron phosphate material. Among them, the chemical formula of lithium manganese iron phosphate is Li a mn x Fe y m 1-x-y P b o 4 , where a=1, x=0.5, y=0.5, b=1.00.

[0041] First prepare the surface iron-rich precursor, according to the stoichiometric ratio of lithium manganese phosphate, weigh lithium acetate, manganese phosphate (trivalent) hydrate (D 50 =200nm), ferric nitrate, and ammonium dihydrogen phosphate as raw materials, dispersed in deionized water, and adding 10 mol% sucrose relative to (Mn+Fe+M) moles as a carbon source, to prepare 1mol of lithium manganese iron phosphate precursor . Stir the slurry at 200r / min for 0.5h, and the...

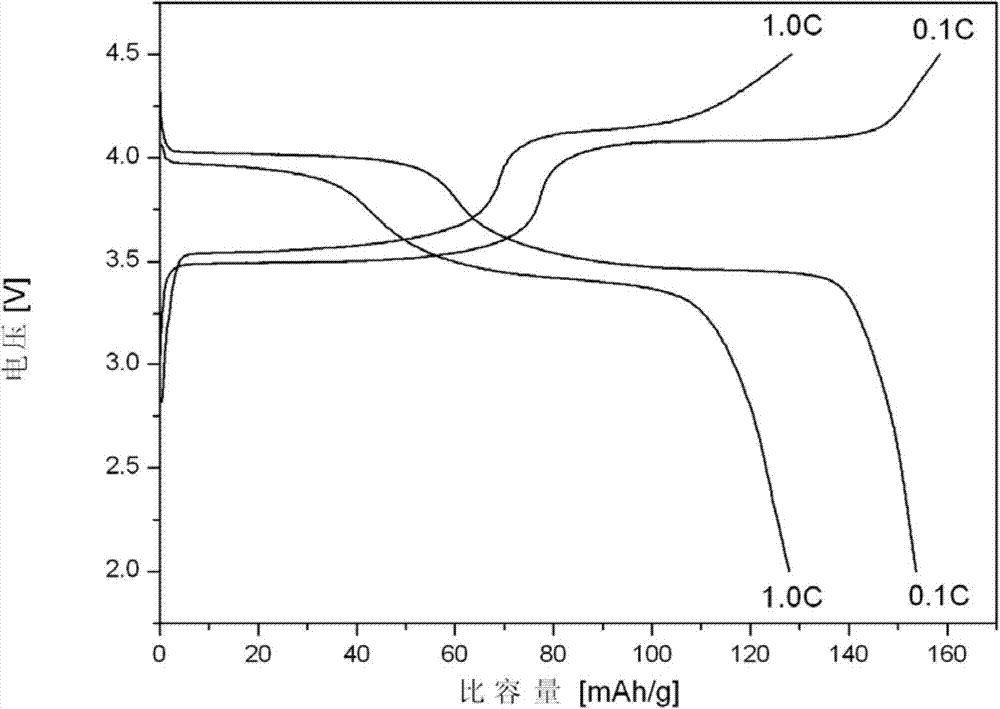

Embodiment 2

[0045] Carbon-coated lithium manganese iron phosphate materials were prepared based on precursors rich in iron on the surface and rich in manganese in the core. In this method, the precursor is obtained first, and then mixed with other soluble raw materials to prepare carbon-coated lithium manganese iron phosphate material. Among them, the chemical formula of lithium manganese iron phosphate is Li a mn x Fe y m 1-x-y P b o 4 , where a=1.06, x=0.75, y=0.23, b=1.01, M=Zn.

[0046] First prepare the surface iron-rich precursor, according to the stoichiometric ratio, weigh manganese carbonate (D 50 =150nm), ferric citrate, zinc nitrate raw materials, the surface iron-rich precursor of preparing 1mol of lithium manganese iron phosphate. Put several raw materials into deionized water, stir for 0.5h, then dropwise add 0.1mol / L ammonia water and keep stirring until the soluble iron source and zinc source are completely converted into the precipitate coating layer on the surface...

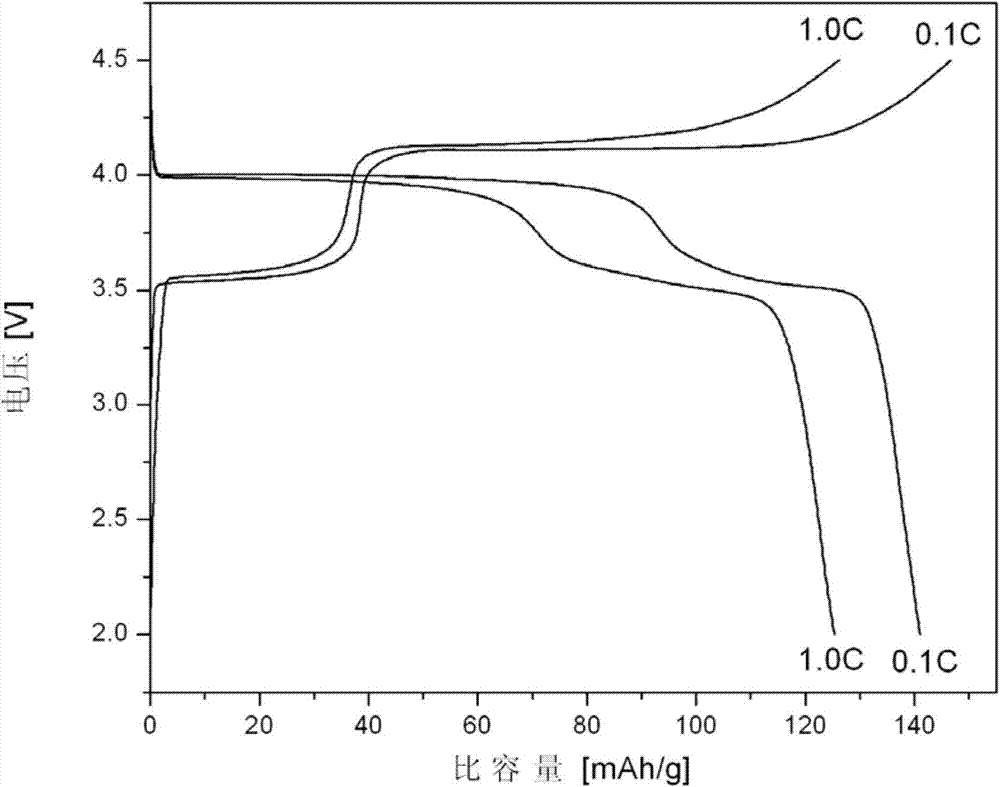

Embodiment 3

[0051] Carbon-coated lithium manganese iron phosphate materials were prepared based on precursors rich in iron on the surface and rich in manganese in the core. In this method, the precursor is not separated after preparation, and other raw materials are directly added to it for reaction to prepare a carbon-coated lithium manganese iron phosphate material. Among them, the chemical formula of lithium manganese iron phosphate is Li a mn x Fe y m 1-x-y P b o 4 , where a=0.97, x=0.35, y=0.63, b=0.98, M=Mg.

[0052] First prepare the surface iron-rich precursor, according to the stoichiometric ratio, weigh ammonium manganese phosphate (D 50 =100nm), ferric citrate, and magnesium acetate as raw materials to prepare a surface iron-rich precursor of 1 mol of lithium manganese iron phosphate. Put several raw materials into deionized water, stir for 0.7h, then dropwise add 0.2mol / L ammonia water and keep stirring until the soluble iron source and magnesium source are completely c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com