Niw(x) sputtering target with improved structure

A technology for sputtering targets and metals, which is applied in the field of sputtering targets and can solve problems such as cracks in target material layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

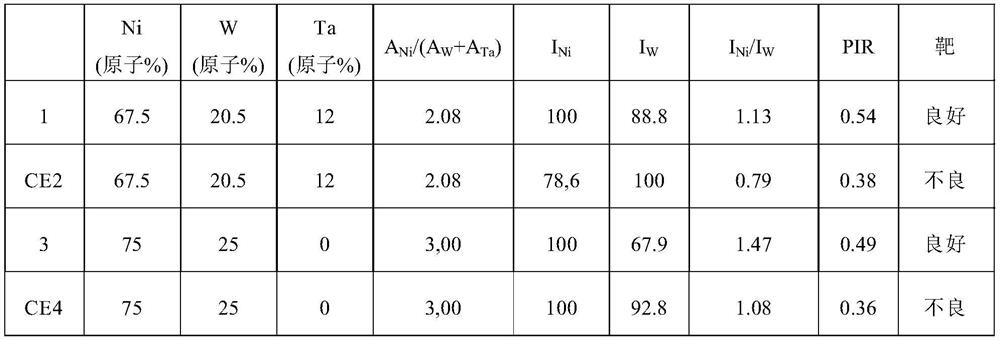

[0060] In order to illustrate the present invention, several examples and comparative examples were carried out. Spray powders were prepared by mixing elemental powders in a tube mixer for 3 hours. Generally, powders with a particle size in the range of 30 to 120 μm will give suitable results. Especially for W, too large granularity should be avoided. These powder mixtures were used for plasma spraying on SST tubes having an outside diameter (OD) of 133 mm and a length of 550 mm, the ends of which were capped by cap rings.

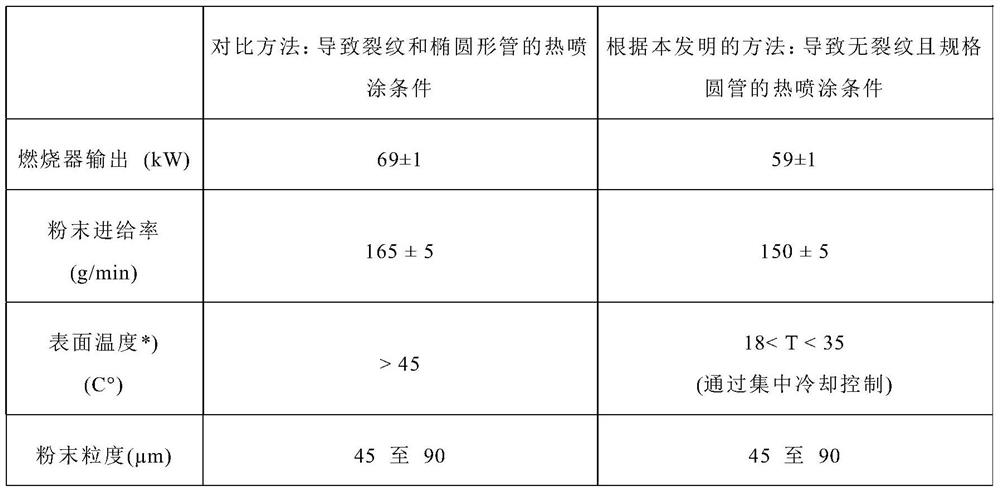

[0061] In Table 1 the thermal spraying conditions for comparative Ni / W / Ta targets and targets according to the invention are listed.

[0062] Table 1:

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com