Sintered NdFeB rear-earth permanent magnet with fine magnetization characteristic and manufacturing method thereof

A technology of rare earth permanent magnets and magnetization characteristics, applied in the field of sintered NdFeB rare earth permanent magnets, manufacturing the sintered NdFeB rare earth permanent magnets, can solve the problems of uneven composition and structure, achieve uniform internal structure, and expand application Scope, the effect of realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

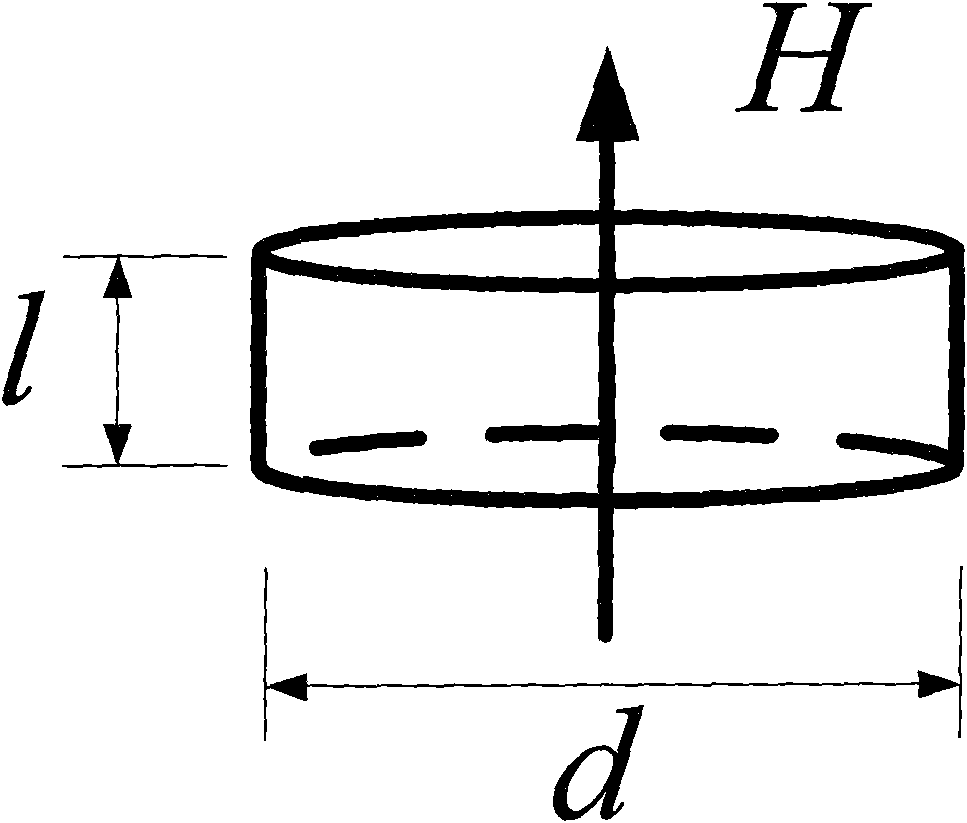

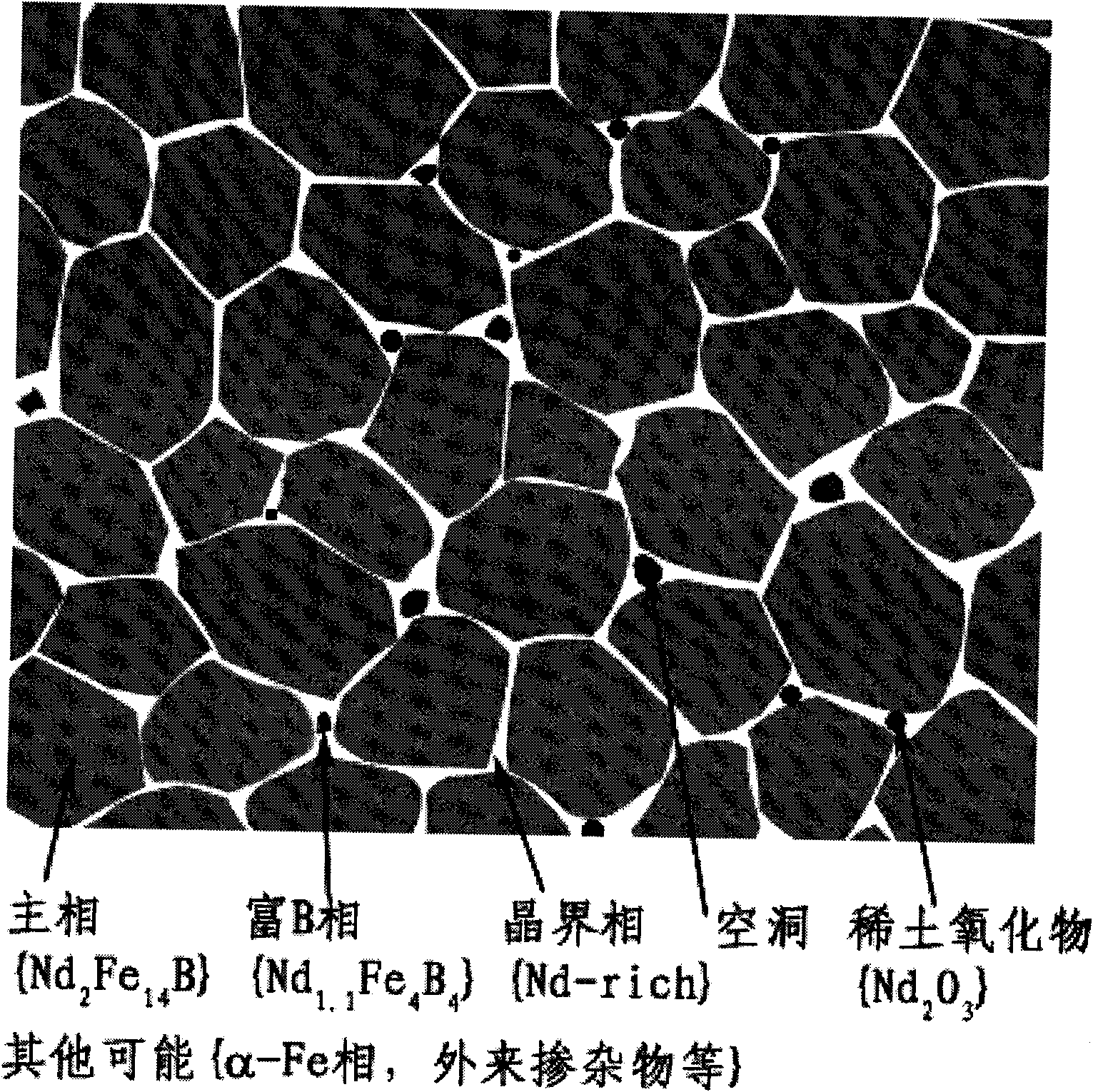

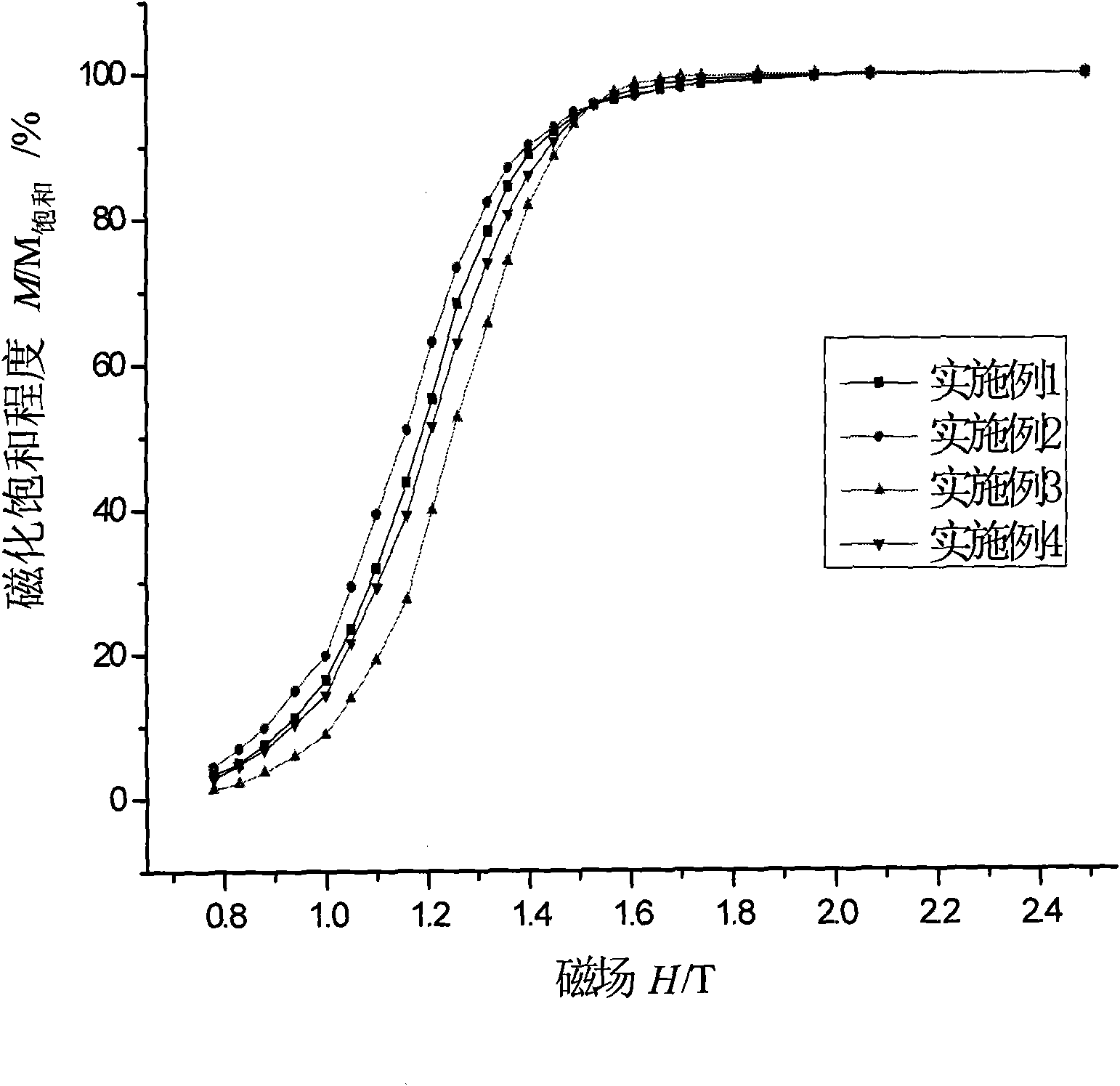

[0042] Melting Ingot Alloy R 1 FeMB, the ingot alloy was coarsely crushed by the conventional method, and after hydrogen crushing, it was mixed with R 2 Oxide powder (Yb 2 o 3 , Tb 2 o 3 、Dy 2 o 3 ) mixed, jet milled into fine magnetic powder, and then mixed evenly, the final composition is obtained (Nd, Pr) a (Yb, Dy, Tb) b Fe 100-a-b-c-d (Cr, Co, Cu, Al, Nb) c B d (a, b, c, d are atomic percentages) of fine magnetic powder, wherein a, b, c, d take 1) a=8.5, b=5, c=0, d=5; 2) a=10, b=2.5, c=1.5, d=5.5; 3) a=15, b=1, c=3, d=6; 4) a=15, b=0, c=3, d=6. Put the 4 kinds of magnetic powder into the pulsed magnetic field magnetizer with the maximum magnetic field up to 7T for pre-orientation, then oriented by 2T magnetic field and press-molded, after 180MPa isostatic pressing, the green body is sintered at 1000-1100℃ for 3-4h, 500-600 Tempering at ℃ for 3 to 5 hours to obtain 4 kinds of rough magnets, and then cut into cylindrical magnets of Φ10mm×2mm. The magnetization...

Embodiment 5~11

[0046] Melting Ingot Alloy R 1 FeMB, the ingot alloy was coarsely crushed by the conventional method, and after hydrogen crushing, it was mixed with R 2 Oxide (Yb 2 o 3 , Tb 2 o 3 、Dy 2 o 3 ) powders are mixed, made into fine magnetic powder by jet milling, and then mixed evenly, and the final composition is (Nd, Re) a (Yb, Dy, Tb) b Ee 100-a-b-c-d (Cr, Co, Cu, Al, Nb) c B d (a, b, c, d are atomic percentages) fine magnetic powder, wherein Re is selected from one of Sc, Y, La, Ce, Pm, Sm, Eu, a, b, c, d take a=11.5, b=3, c=1.5, d=5.5. Put the magnetic powder into a pulsed magnetic field magnetizer with a maximum magnetic field of 7T for pre-orientation, and then oriented by a 2T magnetic field and pressed into shape. After isostatic pressing at 180MPa, the green body is sintered at 1070°C for 3h and tempered at 550°C for 4h to obtain a rough magnet. After that, it is cut into a cylindrical magnet of Φ10mm×2mm. Test the magnetization curve of the magnet, record eac...

Embodiment 12~18

[0048] Melting Ingot Alloy R 1 FeMB, the ingot alloy was coarsely crushed by the conventional method, and after hydrogen crushing, it was mixed with R 2 Oxide (Yb 2 o 3 , Tb 2 o 3 、Dy 2 o 3 ) powder mixed, made into fine magnetic powder by jet mill, and then mixed evenly, the final composition is (Nd, Pr.Re) a (Yb, Dy, Tb) b Fe 100-a-b-c-d (Cr, Co, Cu, Al, Nb) c B d (a, b, c, d are atomic percentages) fine magnetic powder, wherein Re is selected from one of Sc, Y, La, Ce, Pm, Sm, Eu, a, b, c, d take a=11.5, b=3, c=1.5, d=5.5. Put the magnetic powder into a pulsed magnetic field magnetizer with a maximum magnetic field of 7T for pre-orientation, and then oriented by a 2T magnetic field and press-molded. After 180MPa isostatic pressing, the green body is sintered at 1060°C for 4h, and tempered at 500°C for 3.5h to obtain a rough magnet. , and then cut into Φ10mm×2mm cylindrical magnets. Test the magnetization curve of the magnet, record each process parameter and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com