Substrate for power module, preparing method thereof, substrate with heat radiator and power module

A power module and substrate technology, which is applied in semiconductor devices, electrical solid state devices, cooling/ventilation/heating transformation, etc., can solve the problems of power module reliability decline, circuit layer fluctuations or wrinkles, etc., to suppress the bonding interface and improve bonding Excellent reliability and thermal cycle reliability

Inactive Publication Date: 2011-09-21

MITSUBISHI MATERIALS CORP

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] However, when the circuit layer is made of aluminum with a relatively low deformation resistance such as 99.99% or higher purity (4N aluminum), there is a problem that undulations or wrinkles are generated on the surface of the circuit layer during load heat cycles.

If undulations or wrinkles occur on the surface of the circuit layer, the reliability of the power module will decrease due to cracks in the solder layer.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0252] A comparative test conducted to confirm the effectiveness of the present invention will be described.

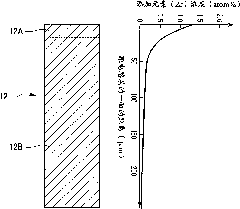

[0253] First, the additive elements shown in Table 1 were fixed to one surface of a metal plate made of 4N aluminum with a thickness of 0.6 mm, and the surface hardened layer and the main body layer were formed by heating. Table 1 shows the fixation amount and heating conditions of the added elements.

[0254] [Table 1]

[0255]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Indentation hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

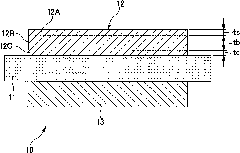

The present invention provides a substrate for a power module, a preparing method thereof, a substrate for the power module with a heat radiator, and the power module thereof. In thermal circulation load, the power module can restrain fluctuation or corrugation on a surface of a circuit layer. Furthermore, application of a thermal stress on a joint interface between a ceramic substrate and the circuit layer can be restrained. Additionally, the substrate for the power module has excellent thermal circulation reliability. The substrate (10) for the power module is provided with an aluminum circuit layer (12) on one surface of the ceramic substrate (11), wherein, the circuit layer (12) is provided with a body layer (12B) and a hardened surface layer (12A) which is configured exposed at the surface side. The indentation hardness (Hs) of the surface of the circuit layer (12) is set in a range between 50mgf / mu m2 and 200mgf / mu m2. More than 80% of the area of the indentation hardness (Hs) becomes the hardened surface layer (12A). The indentation hardness (Hb) of the body layer (12B) is less than 80% of the indentation hardness (Hs).

Description

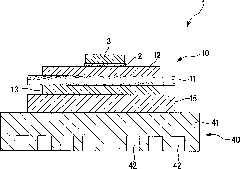

technical field [0001] The present invention relates to a substrate for a power module including a circuit layer on which electronic components such as semiconductor elements are mounted, a method for manufacturing the substrate for a power module, a substrate for a power module with a heat sink using the substrate for a power module, and a power module . Background technique [0002] Since the power element used for power supply among semiconductor elements has relatively high heat generation, as the substrate on which the power element is mounted, for example, as shown in Patent Document 1, the following power module substrate is widely used: a substrate made of AlN (nitrogen Al (aluminum) metal plate to be a circuit layer is bonded to a ceramic substrate made of Al-Si based brazing filler metal. [0003] Furthermore, for example, as shown in Patent Documents 2 to 4, there is proposed a substrate for a power module in which an aluminum alloy member is bonded to a ceramic ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01L23/14H01L23/373H01L21/48

CPCH01L2224/32225H01L23/14H05K1/02H05K7/20

Inventor 殿村宏史长友义幸长濑敏之黑光祥郎

Owner MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com