Copper-alloy wire rod and manufacturing method therefor

A manufacturing method, copper alloy technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, conductive materials, etc., can solve the problems of increased tensile strength, decreased elongation, decreased strength, etc., and achieves excellent bending fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

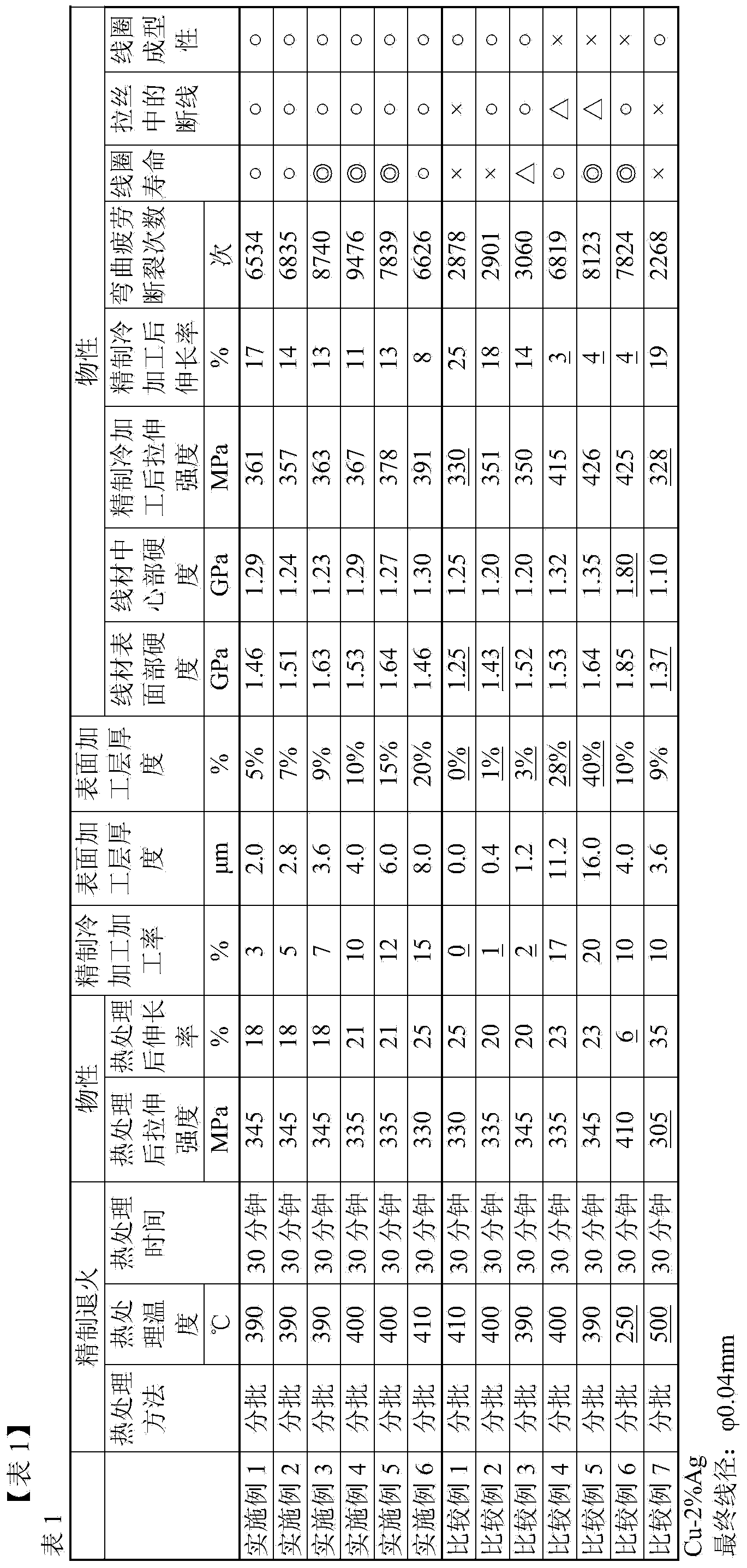

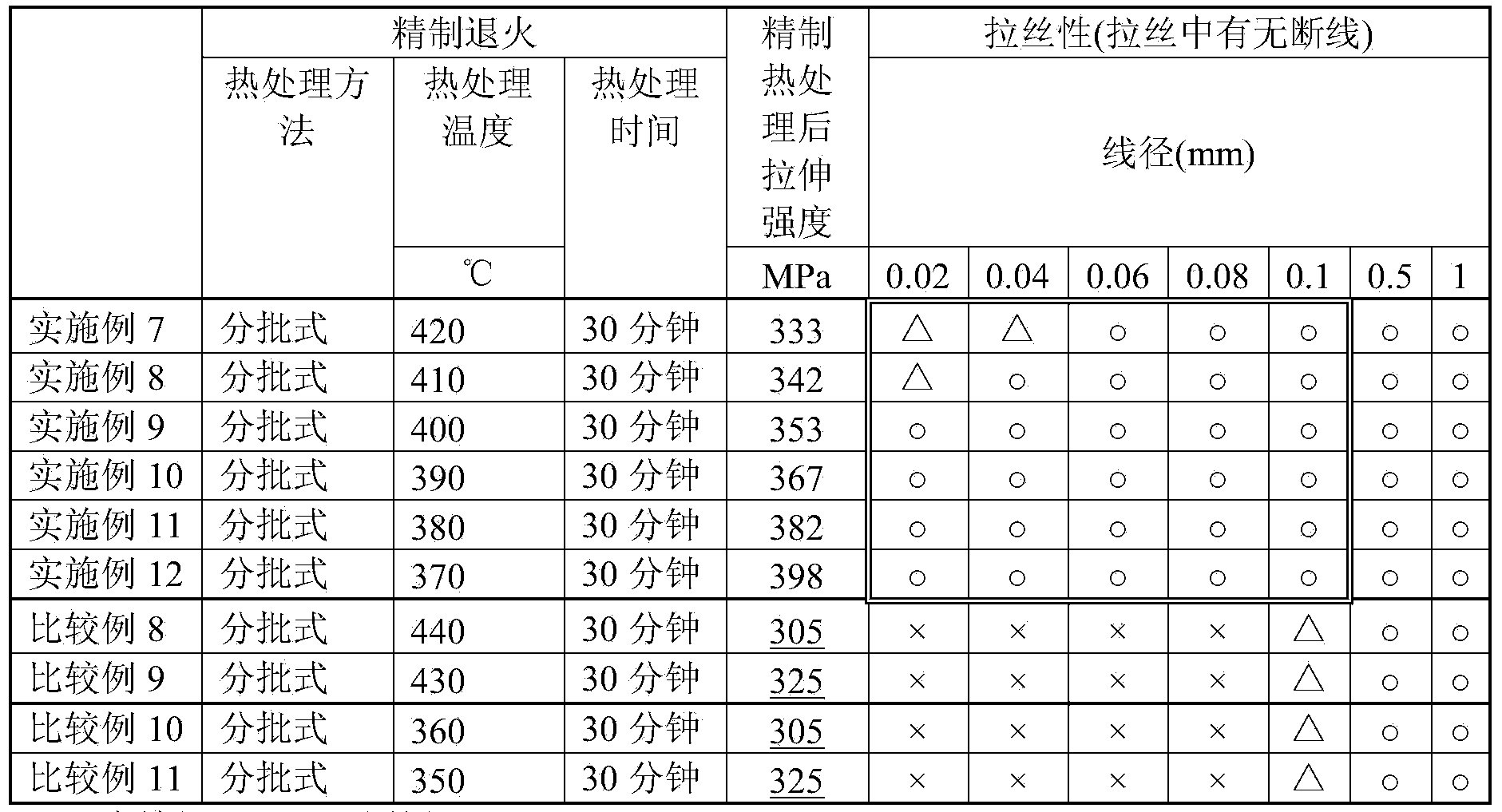

[0095] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to the examples.

[0096] [Example and Comparative Example of Round Wire Rod]

[0097] For casting materials containing 0.5% by mass to 4% by mass of Ag and / or 0.05% by mass to 0.3% by mass of each content selected from the group consisting of Sn, Mg, Zn, In, Ni, Co, Zr and Cr Copper alloys of examples of the present invention having at least one of the various alloy compositions shown in Tables 1 to 3 and the remainder being composed of Cu and unavoidable impurities, and various alloy compositions shown in Tables 1 to 3 The copper alloys of comparative examples were respectively cast into diameters by horizontal continuous casting method drawing blanks.

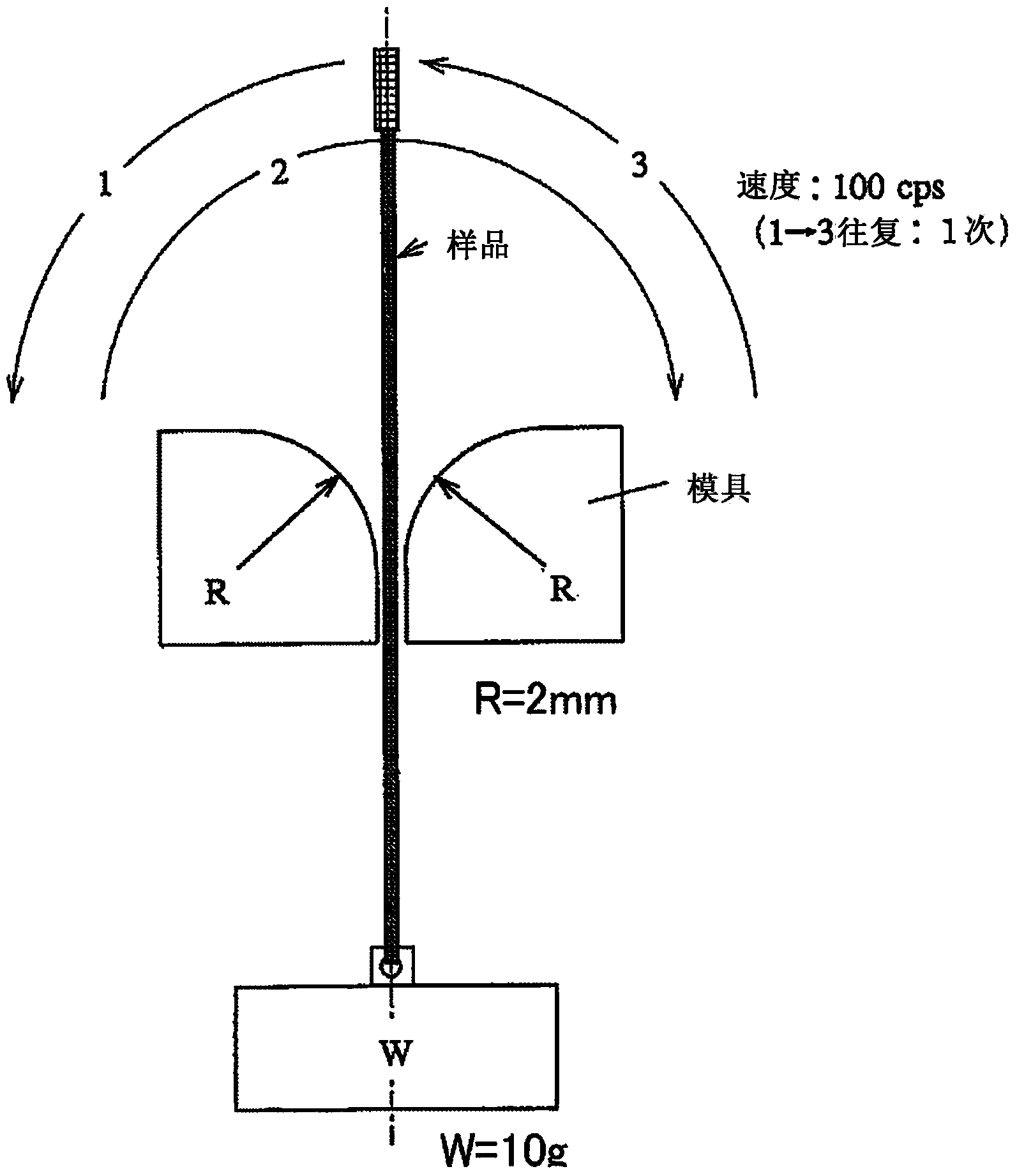

[0098] Cold working (wire drawing), intermediate annealing, finishing annealing, and finishing cold working (wire drawing) were performed on the drawn billet (total processing rate of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com