Plied cord, production method therefor, transmission belt, and method for using same

A technology for transmission belts and twisted ropes, applied in transmission belts, V-belts, textiles and papermaking, etc., can solve the problems of unrecorded pop-up resistance, inability to fully satisfy bending fatigue resistance, etc., and achieve the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11 and comparative example 1~12

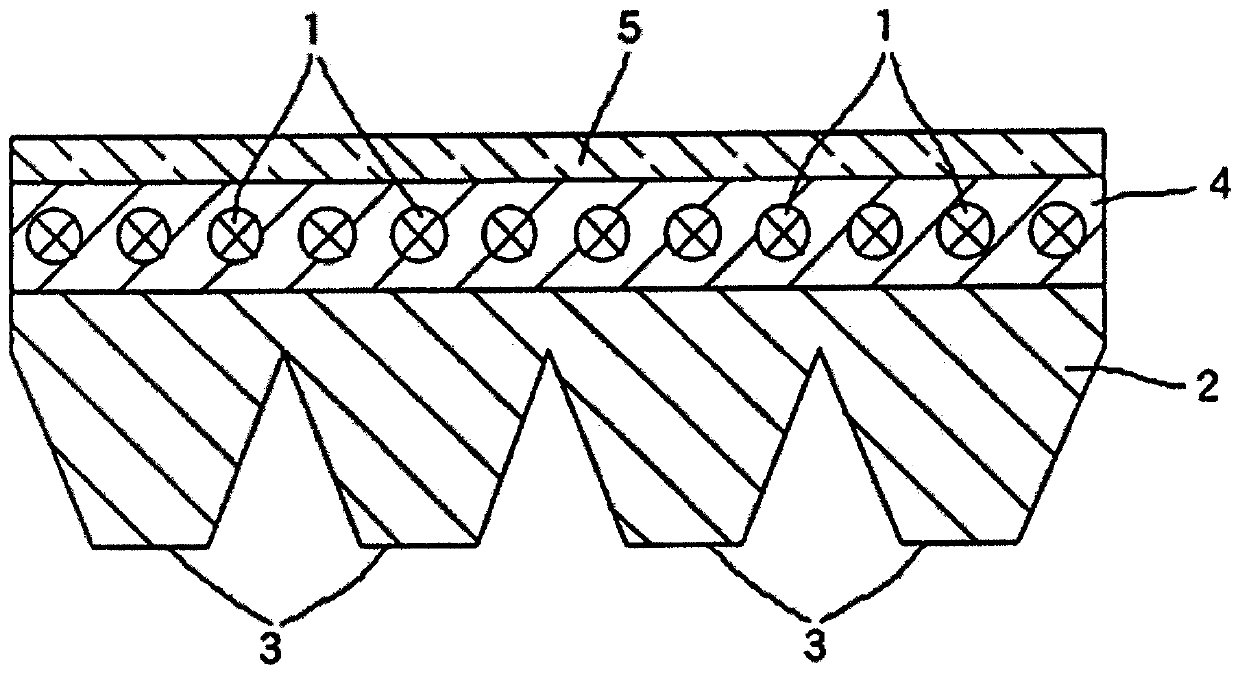

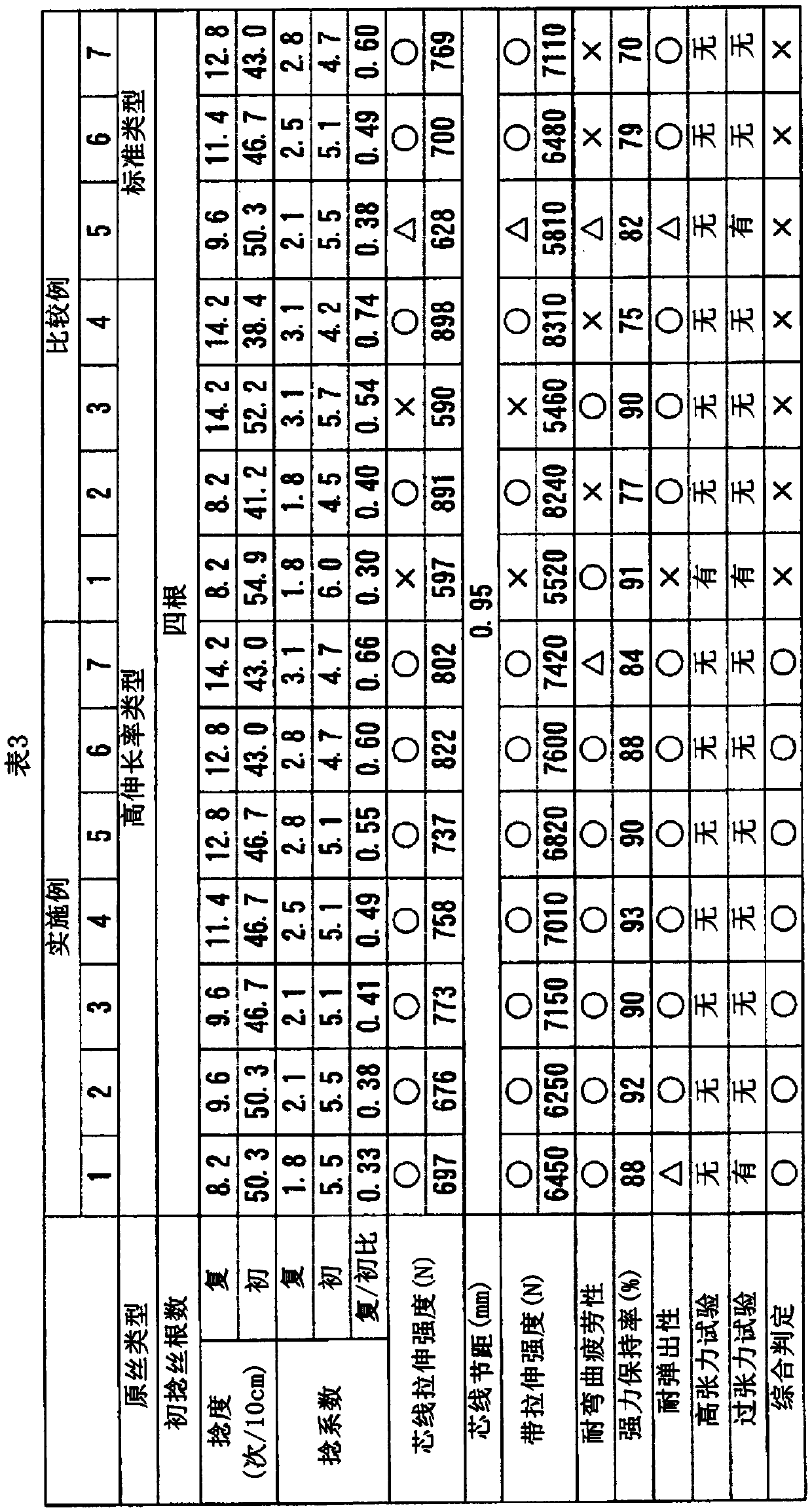

[0088] [Making of core wire]

[0089] As the core wires used in Examples 1 to 7 and Comparative Examples 1 to 4, the multifilaments (denier: 1100 decitex) of para-aramid fibers of a single repeating unit of the high elongation type are listed in Table 3 The indicated initial twist is first twisted along one direction, and after the four strands are aligned, the double twist is performed along the opposite direction to the initial twist at the double twist shown in Table 3, so as to make the total fineness of 4400 dtex respectively. Ply twist rope (S twist, Z twist). The ply-twisted rope obtained in this way was dipped in the prepreg solution for 10 seconds, and then heat-treated at 180° C. for 4 minutes. Next, the pre-dipped plied rope was immersed in the RFL treatment solution for 10 seconds, and then heat-treated at 230° C. for 2 minutes. Furthermore, the plied twisted rope after the RFL treatment was immersed in the outer coating treatment solution for 3 seconds, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com