Method for forecasting uniaxial constitutive relation of material according to press hardness

A technique of indenting hardness and constitutive relationship, which is applied in the direction of testing material hardness, etc., and can solve problems such as difficulty in direct correspondence, low prediction accuracy, and inability to predict uniaxial constitutive relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

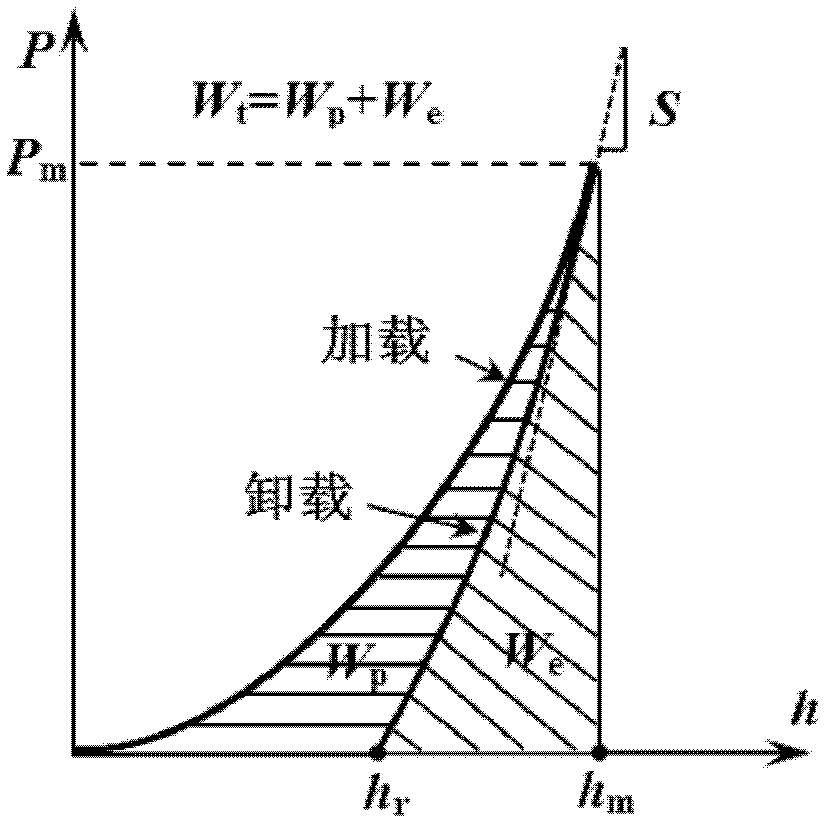

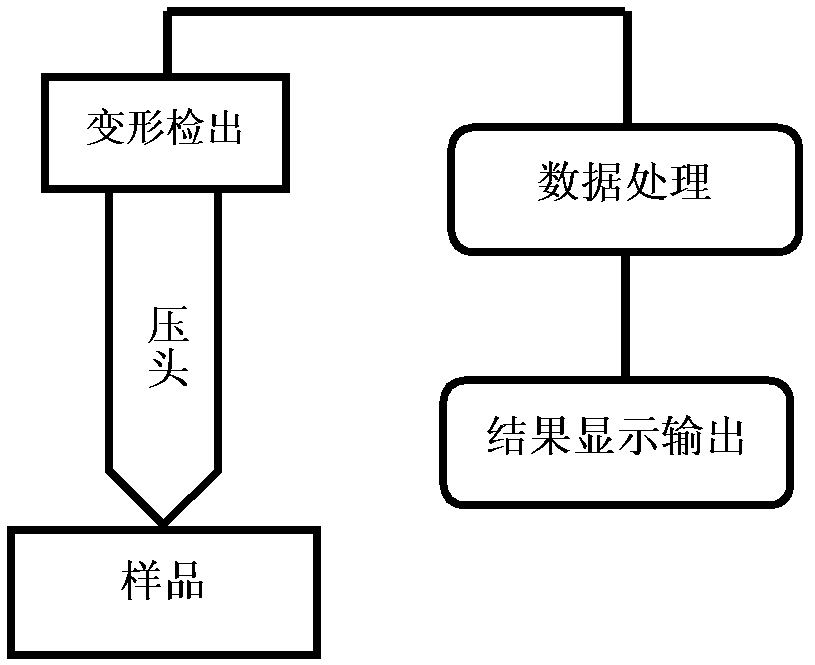

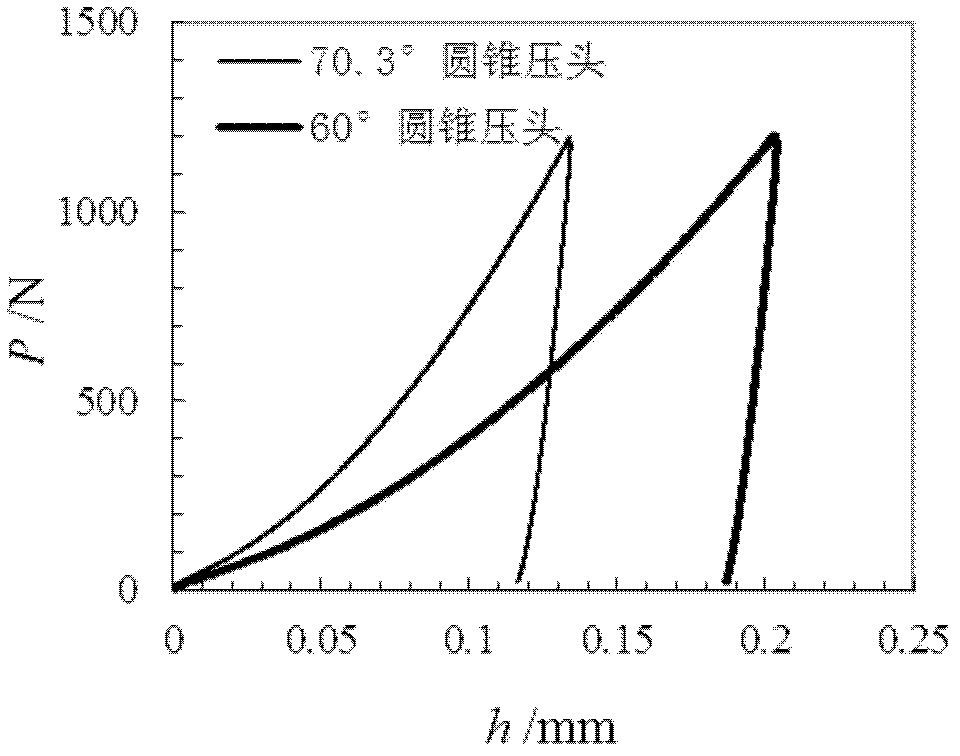

[0047] Indentation hardness tests were carried out on the same T225NG titanium alloy sample using conical indenters with cone half angles of 60° and 70.3° respectively, and the uniaxial constitutive curves were obtained. image 3 Indentation load-depth curves of T225NG titanium alloy samples obtained by indentation tests of 60° and 70.3° conical indenters respectively. The data processing flow is as follows: firstly, the maximum load P is extracted from the press-in load-depth curve max And the corresponding maximum indentation depth h max , and obtain the elastic contact stiffness S from the curve of the unloading section, and then calculate the contact depth between the indenter and the sample Therefore, the indentation hardness of the conical indenter corresponding to different cone angles is Then the hardness H corresponding to the two conical indenters will be obtained C_θ Substituting into formula (5) to obtain the constitutive parameters E, σ y , n, and finally th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com