A composite material used for a special cable, a preparing method thereof and the special cable

A technology of special cables and composite materials, which is applied in the field of power cables, can solve problems such as complex preparation process requirements, reduce cable reliability, and increase product costs, so as to improve fire resistance and wear resistance, improve aging resistance, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

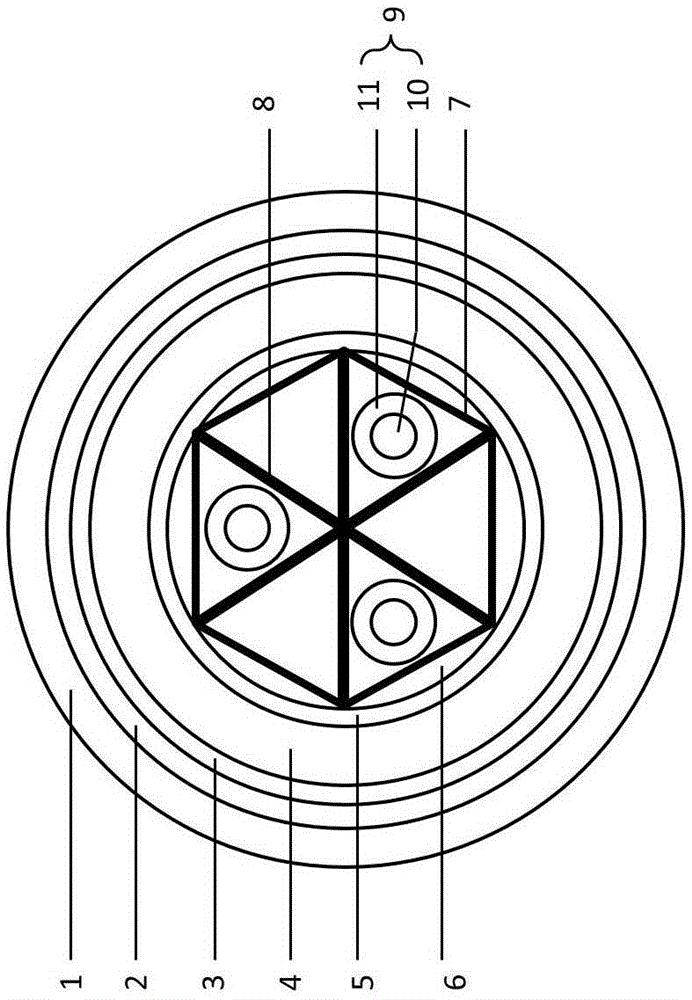

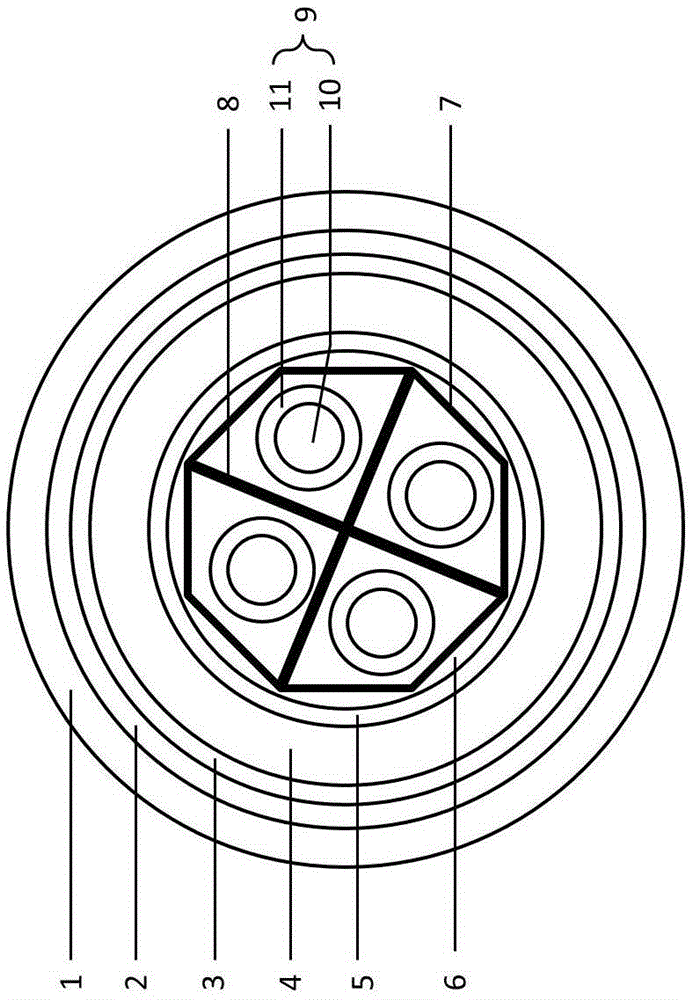

Image

Examples

preparation example Construction

[0055] The preparation of ethylene-vinyl acetate copolymer modified geopolymer adopts the following method to carry out:

[0056] (1) The raw material mixture is configured according to the mass percentage, metakaolin: sodium hydroxide: water glass: water = 100:10:110:1500; the raw material mixture is kept at 60°C for 1 hour, and spray-dried to form a geopolymer powder;

Embodiment 1-1

[0060] Raw materials are prepared in the following proportions (by weight):

[0061] Polyetheretherketone 65

[0062] Polyethylene 20

[0063] Polyimide 20

[0064] Ethylene-vinyl acetate copolymer modified geopolymer 8

[0065] Silicon Nitride Whiskers 4

[0066] Molybdenum trioxide 1.5

[0068] Coupling agent 1.2

[0069] Dicumyl peroxide 0.6.

[0070] Wherein, molybdenum trioxide average particle diameter selects 100nm for use, and magnesium oxide selects the mixture that the average particle diameter of 20wt% is the magnesium oxide of 150nm and the average particle diameter of 80wt% is the mixture of the magnesium oxide of 500nm, and coupling agent selects silane coupling agent for use: titanium Ester coupling agent=2:1.

[0071] (1) Mix silicon nitride whiskers, molybdenum trioxide, magnesium oxide, and coupling agent in proportion to form a mixture, mix the resulting mixture with isopropanol at a mass ratio of 1:2, and perform ultrason...

Embodiment 1-2

[0074] Compared with embodiment 1-1, only the following adjustments are made to the ratio of raw materials:

[0075] In parts by weight:

[0076] PEEK 45

[0077] Polyethylene 30

[0078] Polyimide 10

[0079] Ethylene-vinyl acetate copolymer modified geopolymer 8

[0080] Silicon Nitride Whiskers 5

[0081] Molybdenum trioxide 1.5

[0083] Coupling agent 1.3

[0084] Dicumyl peroxide 0.8.

[0085] Wherein, molybdenum trioxide average particle diameter selects 100nm for use, and magnesium oxide selects the mixture that the average particle diameter of 20wt% is the magnesium oxide of 150nm and the average particle diameter of 80wt% is the mixture of the magnesium oxide of 500nm, and coupling agent selects silane coupling agent for use: titanium Ester coupling agent=2:1.

[0086] The prepared composite material for special cables is designated as sample 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com