Polyetheretherketone-base composite, preparing method thereof and application thereof in friction reduction and wear resistance

A technology of polyether ether ketone and composite materials, applied in the field of polyether ether ketone-based wear-resistant composite materials, anti-friction and wear-resisting, and preparation fields, can solve the problem of low friction coefficient damping performance and self-lubricating ability, which cannot meet the requirements of the application low friction coefficient and wear rate, good dispersion and interfacial compatibility, and reduced wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of 10wt% PEI-coated carbon fiber / 3wt% KH570-TiO 2 / PEEK wear-resistant composite material

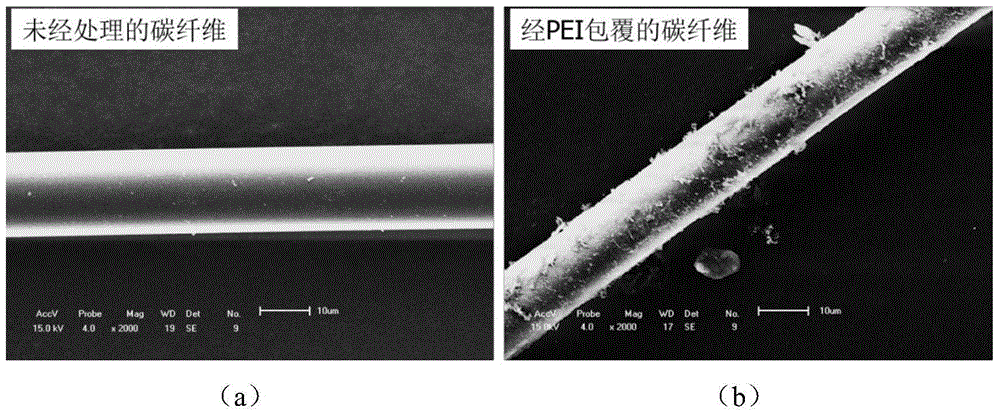

[0028] Add 0.5g of polyetherimide into 30mL of chloroform, stir at 20°C until dissolved, add 10g of carbon fiber, continue stirring at 20°C for 3h, then slowly pour the mixture into absolute ethanol while stirring, After filtering, washing and drying, PEI-coated carbon fibers were obtained, and the mass ratio of carbon fibers to PEI was 20:1.

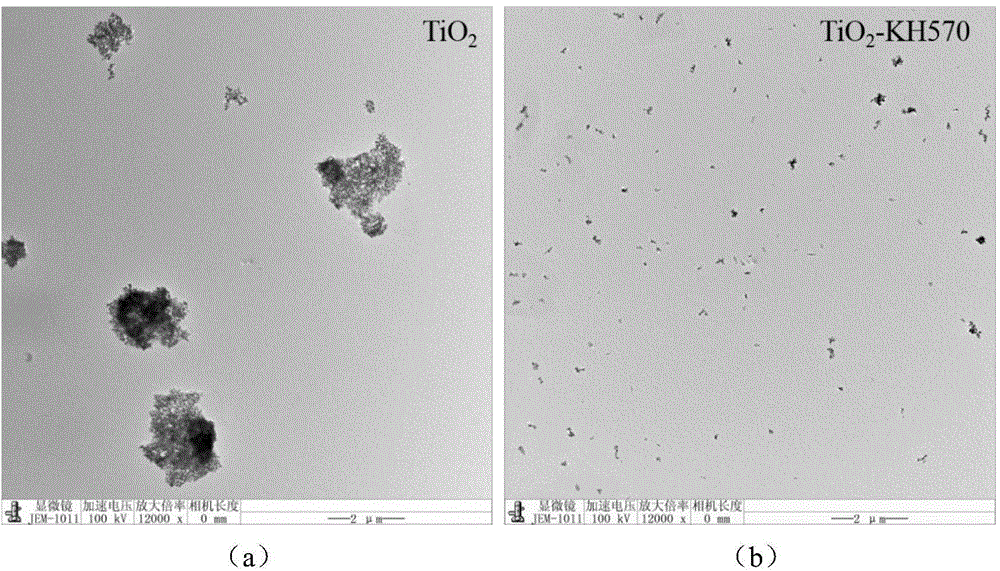

[0029] Add 3g of titanium dioxide to 60mL of ethanol and ultrasonically disperse for 3 hours, add 3mL of distilled water, adjust the pH value of the mixture to 8 with ammonia water, and finally add 0.03g of KH570, react at 50°C for 3 hours, centrifuge, wash and dry to prepare The titanium dioxide modified by KH570 is obtained, and the mass ratio of titanium dioxide and KH570 is 100:1.

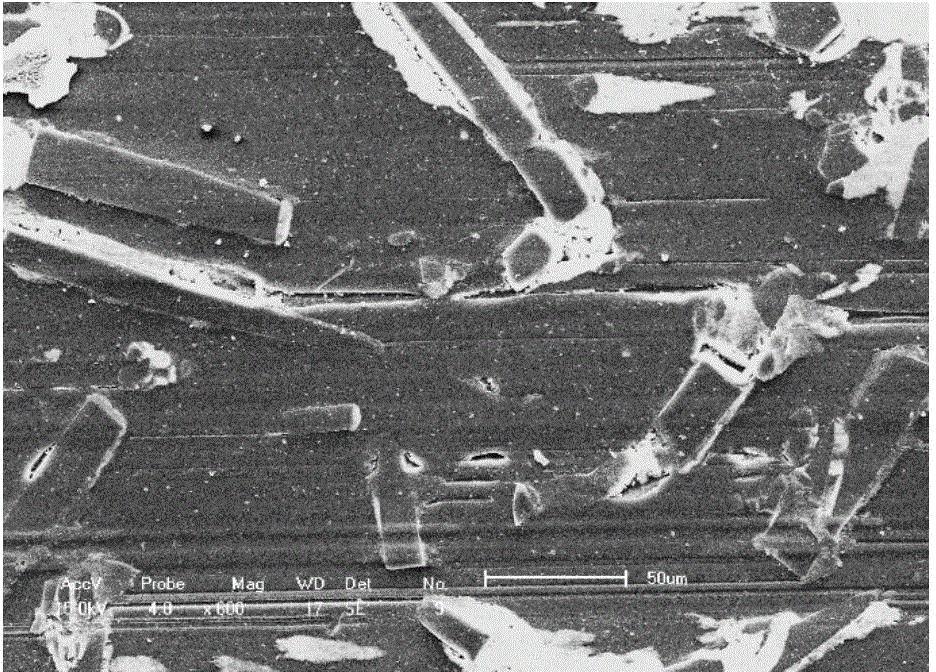

[0030] Add 87g of PEEK, 10g of polyetherimide-coated carbon fiber, and 3g of KH570-modified titanium dioxide into a high-speed mix...

Embodiment 2

[0031] Example 2: Preparation of 10wt% PEI-coated carbon fiber / 5wt% KH570-TiO 2 / PEEK wear-resistant composite material

[0032] Add 1g of polyetherimide to 60mL of chloroform, stir until dissolved at 20°C, add 10g of carbon fiber, continue stirring at 20°C for 3h, then slowly pour the mixture into absolute ethanol while stirring, and filter 1. Drying after washing to obtain PEI-coated carbon fibers, the mass ratio of carbon fibers and PEI is 10:1.

[0033] Add 5g of titanium dioxide to 50mL of ethanol and ultrasonically disperse for 5h, add 5mL of distilled water, adjust the pH value of the mixture to 10 with ammonia water, and finally add 0.25g of KH570, react at 80°C for 1h, centrifuge, wash and dry to prepare The titanium dioxide modified by KH570 is obtained, and the mass ratio of titanium dioxide and KH570 is 20:1.

[0034] Add 85g of PEEK, 10g of polyetherimide-coated carbon fiber, and 5g of KH570-modified titanium dioxide into a high-speed mixer and mix evenly, then ...

Embodiment 3

[0035] Example 3: Preparation of 20wt% PEI-coated carbon fiber / 3wt% KH570-TiO 2 / PEEK wear-resistant composite material

[0036] Add 0.5g of polyetherimide into 30mL of chloroform, stir at 25°C until dissolved, add 20g of carbon fiber, continue stirring at 25°C for 3h, then slowly pour the mixture into absolute ethanol while stirring, After filtering, washing and drying, PEI-coated carbon fibers were obtained, and the mass ratio of carbon fibers to PEI was 40:1.

[0037]Add 3g of titanium dioxide to 40mL of ethanol and ultrasonically disperse for 4 hours, add 3.2mL of distilled water, adjust the pH of the mixture to 9 with ammonia water, and finally add 0.06g of KH570, react at 60°C for 2 hours, centrifuge, wash and dry to prepare The titanium dioxide modified by KH570 is obtained, and the mass ratio of titanium dioxide and KH570 is 50:1.

[0038] Add 77g of PEEK, 20g of polyetherimide-coated carbon fiber, and 3g of KH570-modified titanium dioxide into a high-speed mixer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com