Antistatic high-temperature-resistant poly(ether-ether-ketone) coating and preparation method of antistatic high-temperature-resistant coating

An antistatic and high temperature resistant, polyether ether ketone technology, applied in the field of coatings, can solve the problems of easy sinking, easy aggregation and high surface energy, and achieve the effects of simple and convenient preparation method, superior physical properties and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

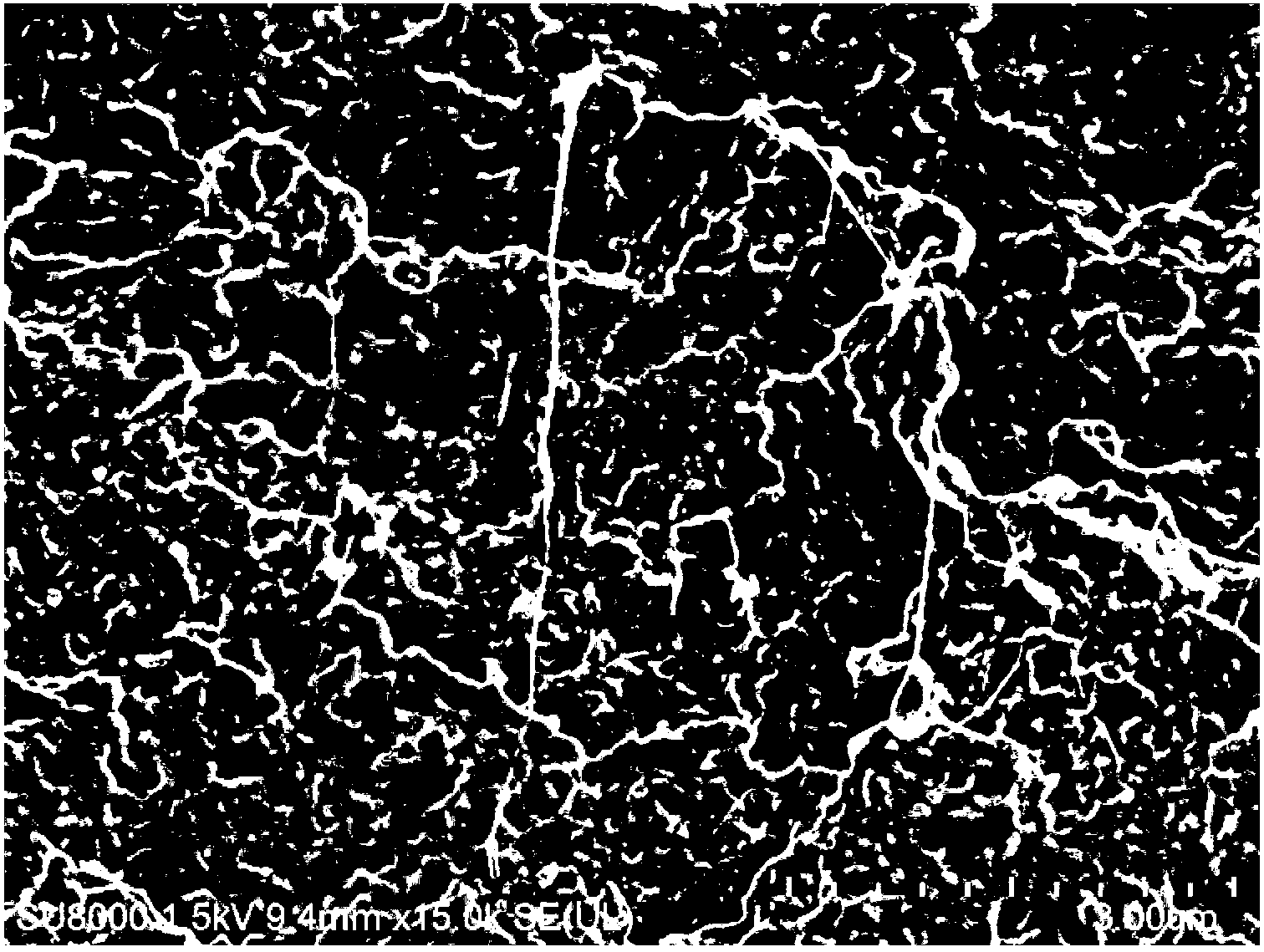

[0024] (1) Disperse 119.4g of polyetheretherketone resin with a melt index of 80g / 10min in 1194.0g of distilled water, grind it in a colloid mill (model: JTM5AB) for 20 minutes, filter it through a 200-300 mesh screen, and dry it at 120°C After 12 hours, polyetheretherketone powder of 200-300 meshes was obtained; the polyetheretherketone powder and 0.6 g of multi-walled carbon nanotubes with a diameter of 10-20 nm and a length of 10-30 μm were mixed in a high-speed pulverizer at 5000 The speed of rev / min was mixed for 5 minutes to obtain a mixed coating;

[0025] (2) After the surface of the steel plate is treated with a sandblasting machine, it is cleaned with ethanol and acetone, and the sandblasted steel plate is obtained after drying; the sandblasting sand particle size is 50 μm;

[0026] (3) The mixed paint was sprayed on the sandblasted steel plate by electrostatic spraying technology, kept at 380° C. for 10 minutes and then cooled at room temperature to obtain an antist...

Embodiment 2

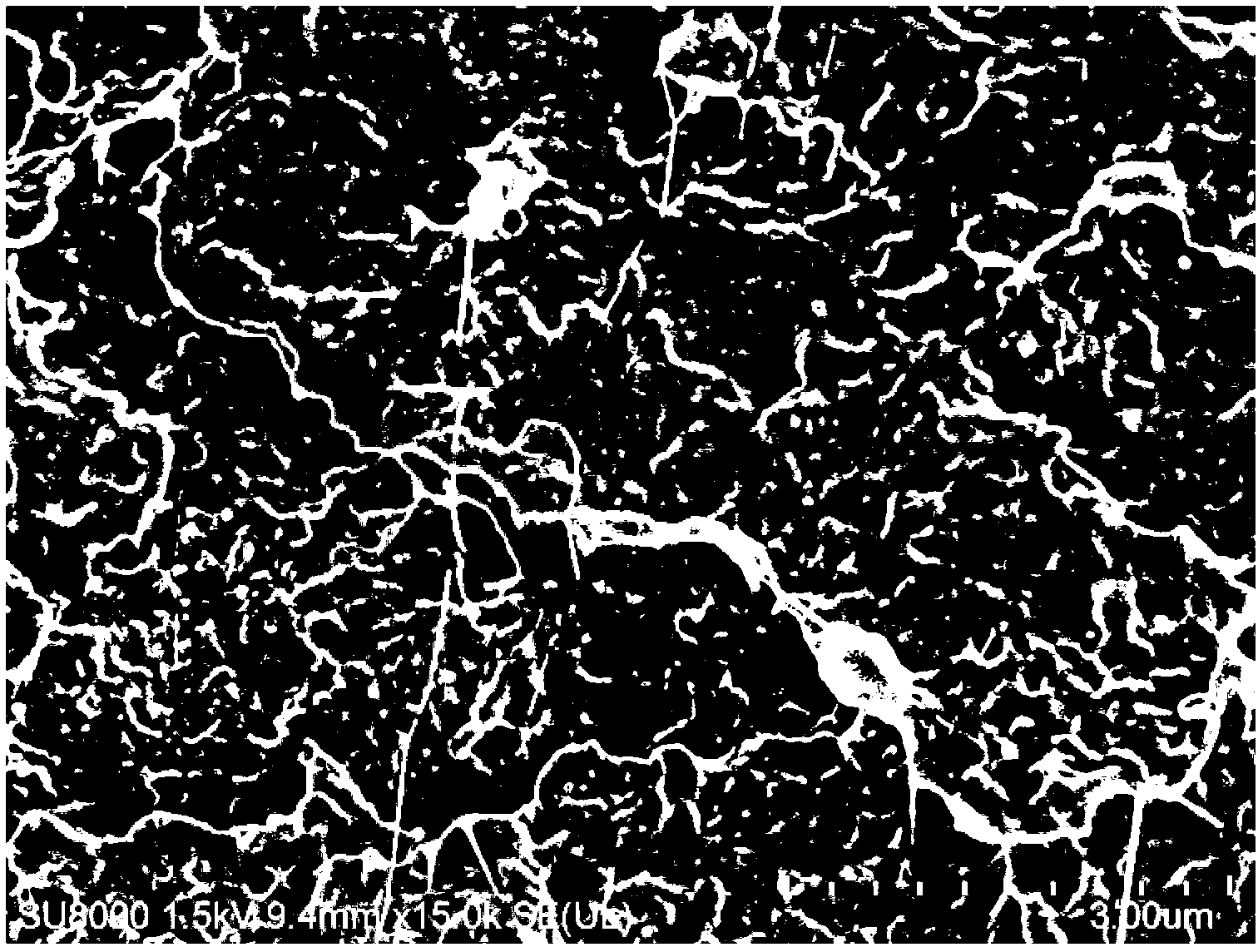

[0030] (1) Disperse 119.40g of polyetheretherketone resin with a melt index of 120g / 10min in 1194.0g of distilled water, grind it in a colloid mill (model: JTM5AB) for 20 minutes, filter it through a 300-400 mesh screen, and dry it at 120°C After 12 hours, 300-400 mesh polyether ether ketone powder was obtained; the polyether ether ketone powder and 0.6 g of multi-walled carbon nanotubes with a diameter of 10-20 nm and a length of 10-30 μm were mixed in a high-speed pulverizer at 10,000 The speed of rev / min was mixed for 5 minutes to obtain a mixed coating;

[0031] (2) After the surface of the steel plate is treated with a sandblasting machine, it is cleaned with ethanol and acetone, and the sandblasted steel plate is obtained after drying; the sandblasting sand particle size is 50 μm;

[0032] (3) The mixed paint was sprayed on the sandblasted steel plate by electrostatic spraying technology, kept at 420° C. for 30 minutes and then cooled at room temperature to obtain an ant...

Embodiment 3

[0036] (1) Disperse 118.8g of polyether ether ketone resin with a melt index of 80g / 10min in 1188.0g of distilled water, grind it in a colloid mill (model: JTM5AB) for 20 minutes, filter it through a 200-300 mesh screen, and dry it at 120°C After 12 hours, 200-300 mesh polyether ether ketone powder was obtained; the polyether ether ketone powder and 1.2 g of multi-walled carbon nanotubes with a diameter of 10-20 nm and a length of 10-30 μm were mixed in a high-speed pulverizer at 5000 The speed of rev / min was mixed for 5 minutes to obtain a mixed coating;

[0037](2) After the surface of the steel plate is treated with a sandblasting machine, it is cleaned with ethanol and acetone, and the sandblasted steel plate is obtained after drying; the sandblasting sand particle size is 50 μm;

[0038] (3) The mixed paint was sprayed on the sandblasted steel plate by electrostatic spraying technology, kept at 380° C. for 10 minutes and then cooled at room temperature to obtain an antist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com