Method for preparing sulfonated polymer films

A technology of sulfonated polymer and membrane casting solution, which is applied in the field of preparation of sulfonated polymer membranes, can solve the problems of low polymer sulfonation degree and complicated membrane making process, achieve high water flux, simple preparation process, Effect of High Protein Retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

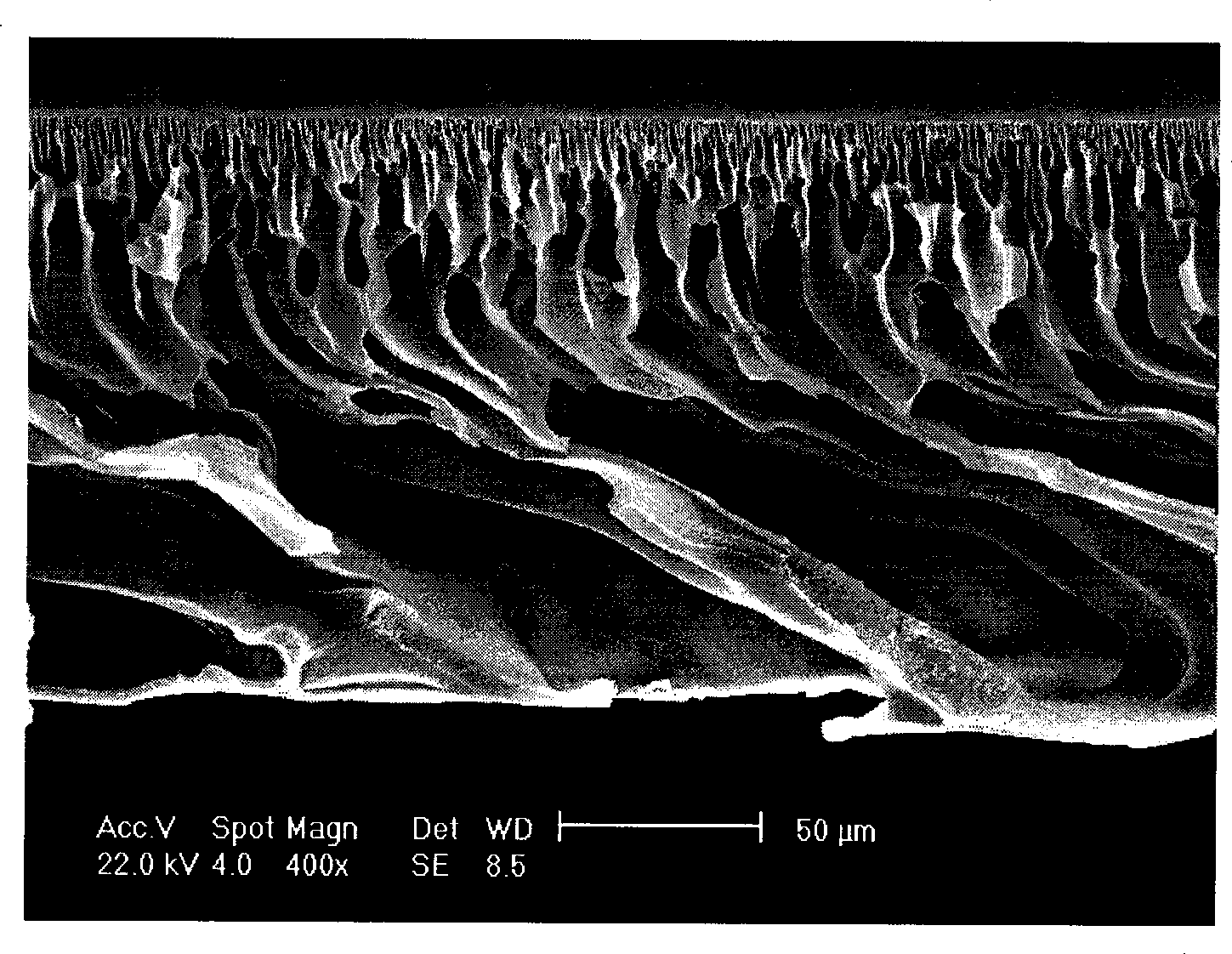

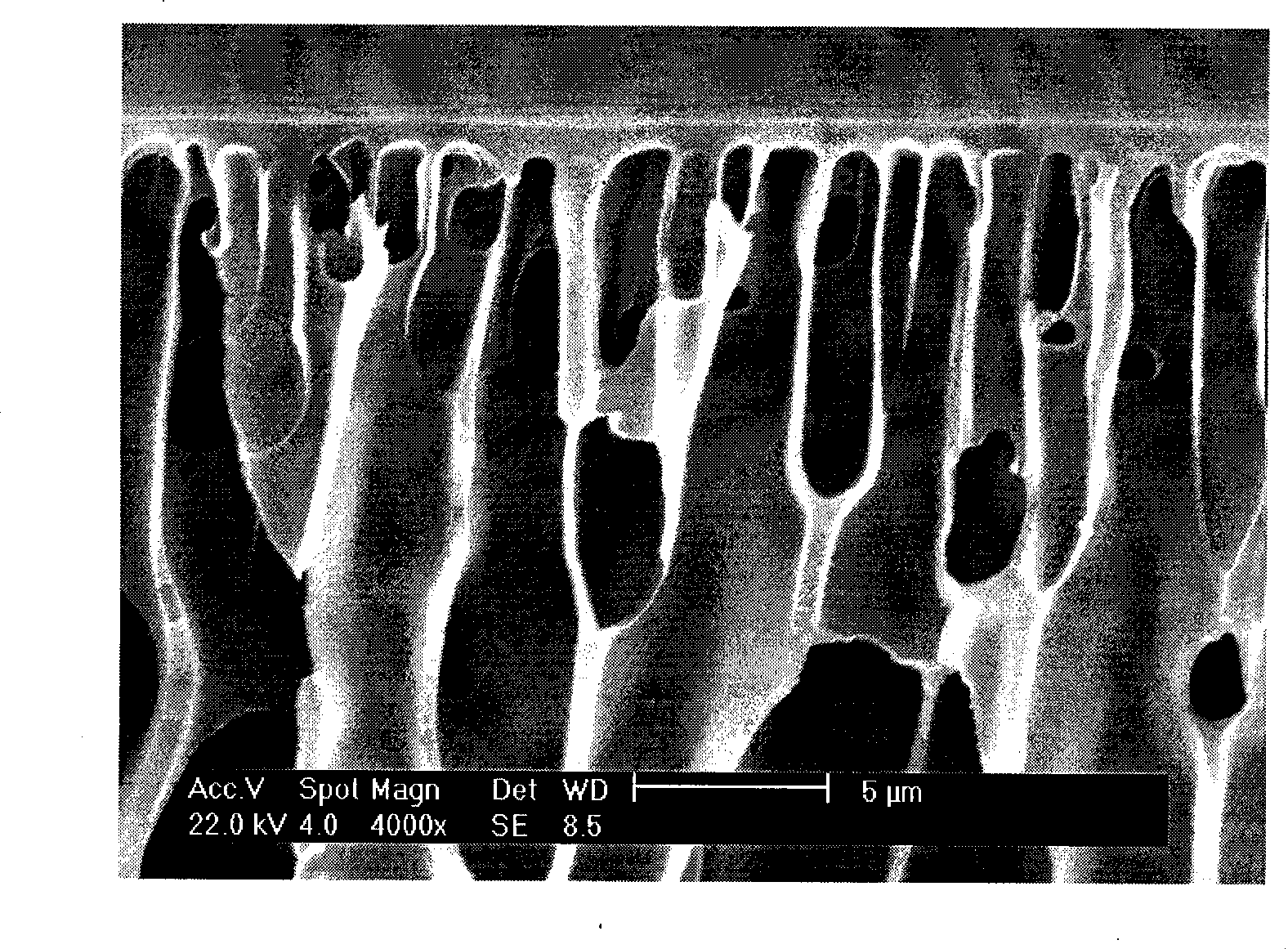

[0022] Add 25 grams of dried polyether ether ketone and 220 ml of 98% concentrated sulfuric acid into a dry three-necked flask, stir, and immerse in a constant temperature water bath at 70°C. After reacting for 3 hours, quickly immerse the three-necked flask in an ice-water bath and keep stirring to stop the reaction. Stirring was stopped after 30 minutes. Keep this three-neck flask standing in an ice-water bath for 12 hours to degas the casting solution. Pour the casting solution on the glass plate to scrape the film at room temperature. At this time, adjust the height of the scraper to 200 μm from the glass plate. Immediately after scraping, put the glass plate into non-solvent deionized water to form a film. The temperature of the non-solvent coagulation bath is 5°C . After the membrane was completely detached from the glass plate, it was transferred to fresh deionized water and soaked for later use. The sulfonation degree of this membrane is 70%, and this porous separat...

Embodiment 2

[0024] Add 30 grams of dried phenolphthalein polyethersulfone and 150 ml of dichloroethane into a dry three-necked flask to dissolve completely, slowly add 12 ml of chlorosulfonic acid dropwise and stir, immerse in a constant temperature water bath at 40°C, and react After 5 hours, the three-neck flask was quickly immersed in an ice-water bath, and kept stirring to stop the reaction. Stirring was stopped after 30 minutes. Keep this three-neck flask standing in an ice-water bath for 12 hours to degas the casting solution. Pour the casting solution on the glass plate to scrape the film at room temperature. At this time, adjust the height of the scraper to 200 μm from the glass plate. Immediately after scraping, put the glass plate into a 2mol / L NaOH aqueous solution to form a film. The temperature of the non-solvent bath is 20 ℃. After the membrane was completely detached from the glass plate, it was transferred to fresh deionized water and soaked for later use. The sulfonati...

Embodiment 3

[0026] Add 30 grams of dried polyether ether ketone and 240 ml of 98% concentrated sulfuric acid into a dry three-necked flask, stir, and immerse in a constant temperature water bath at 50°C. After reacting for 4 hours, quickly immerse the three-necked flask in an ice-water bath In, and keep stirring, make reaction stop, add the graphene oxide of 0.5g simultaneously. Stirring was stopped after 60 minutes. Keep this three-neck flask standing in an ice-water bath for 12 hours to degas the casting solution. Pour the casting solution on the glass plate to scrape the film at room temperature. At this time, adjust the height of the scraper to 240 μm from the glass plate. Immediately after scraping, put the glass plate into 20°C deionized water to form a film. After the membrane was completely detached from the glass plate, it was transferred to fresh deionized water and soaked for later use. The degree of sulfonation of the membrane was 55%. This porous separation membrane is tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com