Thermoplastic poly(ether-ether-ketone) type polyimide and preparation method thereof

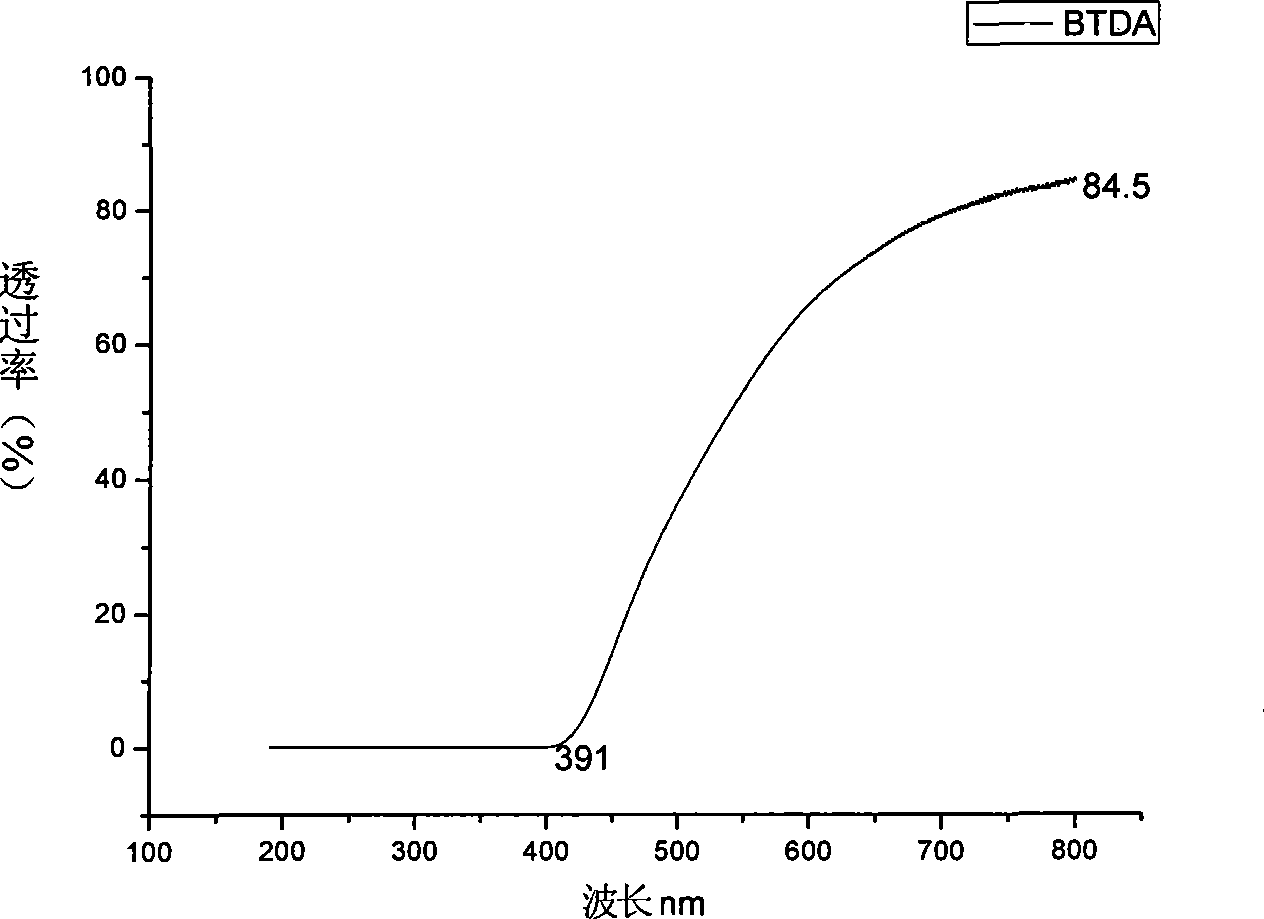

A technology of polyimide and polyetheretherketone, applied in the field of polyimide and its preparation, can solve the problems of limited application field, poor processing performance, etc., and achieve low glass transition temperature, good mechanical properties, high The effect of UV transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Add 5.0054g (0.01mol) of diamine 1,3-bis(3-aminophenoxy-4'-benzoyl)benzene (BABB) into a reaction flask with electromagnetic stirring, and then add N, N-dimethylacetamide (DMAc) 19.8ml, after diamine dissolved, slowly add 2.9422g (0.01mol ), to ensure that the powder does not agglomerate during the addition. After reacting at room temperature for 5 hours, polyamic acid solution PAA was obtained;

[0055] Pour the PAA solution on a clean glass plate, scrape the PAA solution evenly with a 30um spatula, put it into an ordinary oven that has been adjusted to remove the solvent, control the temperature and time, respectively 50°C, 2 hours, 80°C, 2 hours, 100°C, 4 hours, 150°C, 2 hours, 180°C, 1 hour; then transfer the glass plate to a vacuum oven for imidization, control the temperature and time as 200°C, 1 hour, 250°C, 1 hour, 300°C, 1 hour, after the temperature of the oven naturally drops to room temperature, take it out, peel off the film, and obtain a yellow polyimide...

Embodiment 2

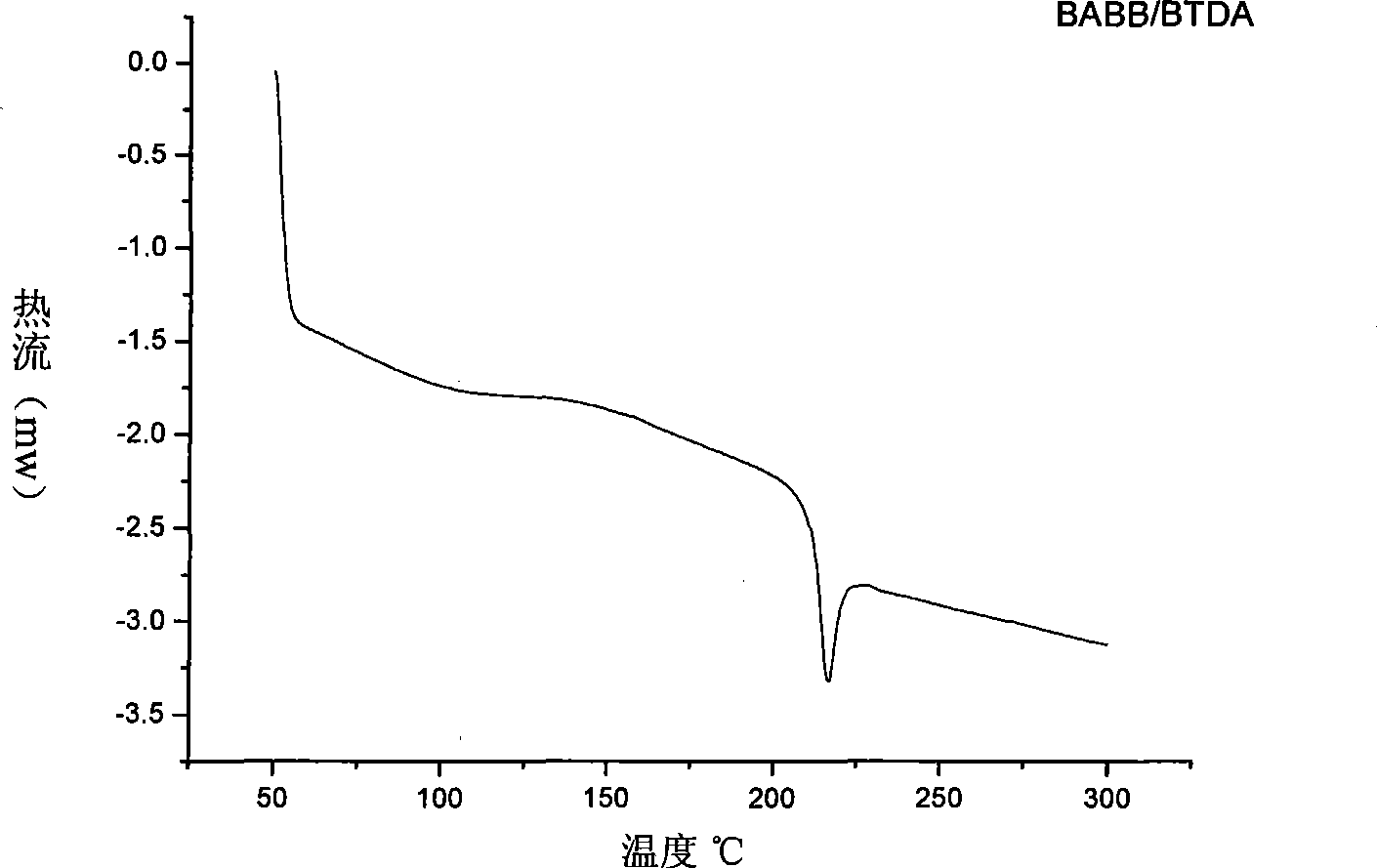

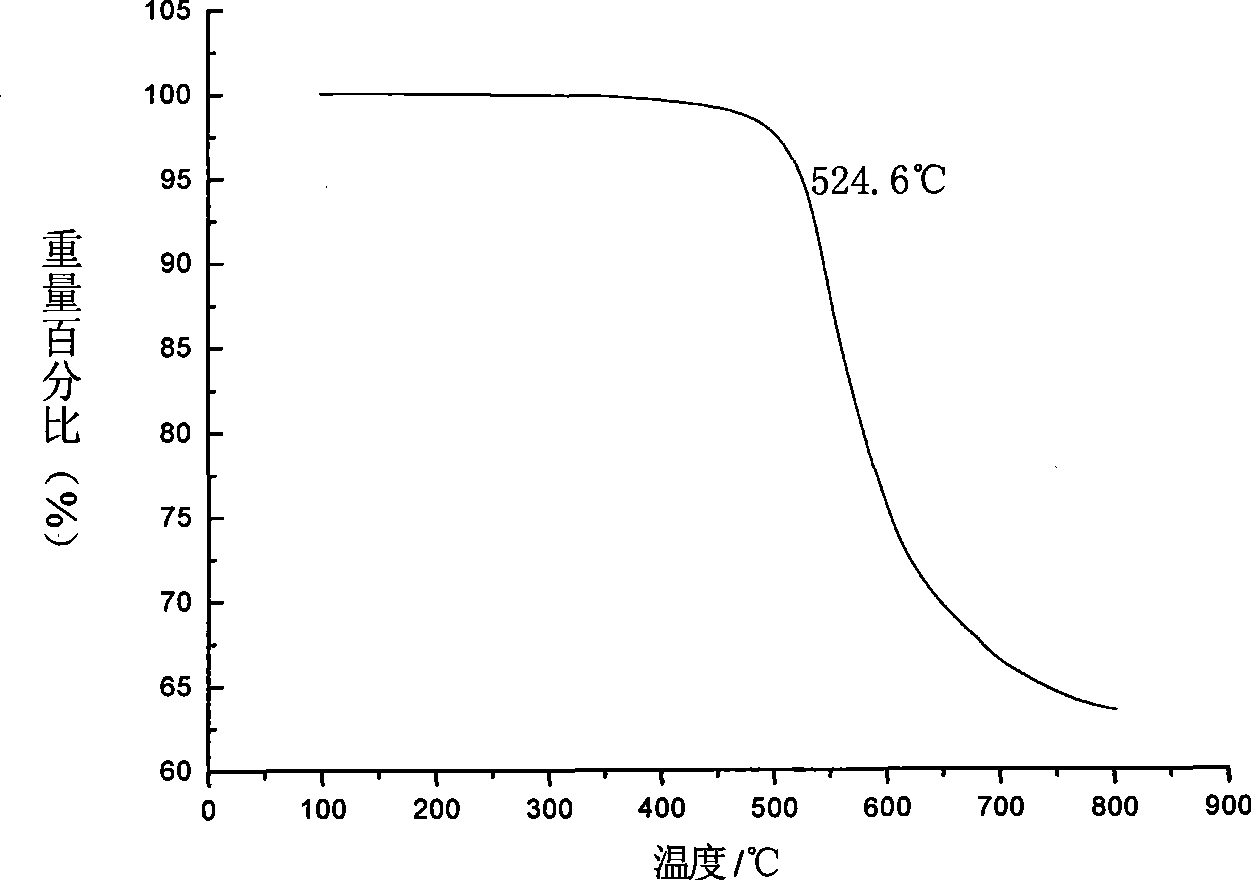

[0056] Add 5.0054g (0.01mol) of diamine 1,3-bis(3-aminophenoxy-4'-benzoyl)benzene (BABB) into a reaction flask with electromagnetic stirring, and then add N, N-dimethylacetamide (DMAc) 20.5ml, after diamine dissolved, slowly add 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA) 3.2223g (0.01mol) , to ensure that the powder does not agglomerate during the addition process. The subsequent treatment process is the same as that in Example 1, and finally a class A brown polyimide polymer film is obtained. The glass transition temperature is about 210°C and the modulus is 3.1GPa.

Embodiment 3

[0058] Add 5.0054g (0.01mol) of diamine 1,3-bis(3-aminophenoxy-4'-benzoyl)benzene (BABB) into a reaction flask with electromagnetic stirring, and then add N, N-dimethylacetamide (DMAc) 17.9ml, after the diamine is dissolved, slowly add 2.1812g (0.01mol) of pyromellitic dianhydride (PMDA) in an equivalent amount to ensure that the powder does not Caking. Its follow-up process is with embodiment 1. Finally, a class A brown polyimide polymer film was obtained. The glass transition temperature is about 225°C and the modulus is 2.6GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com