Aromatic polyetheretherketone-polyimide block polymer, and preparation method and application thereof

A polyimide block and block copolymer technology, applied in the application of polyether ether ketone and thermoplastic polyimide alloy compatibilization modification, in the field of aromatic block copolymer, can solve the problem of different molecular structures and other problems, to achieve the effect of improving mechanical properties, reducing the size of the two phases, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

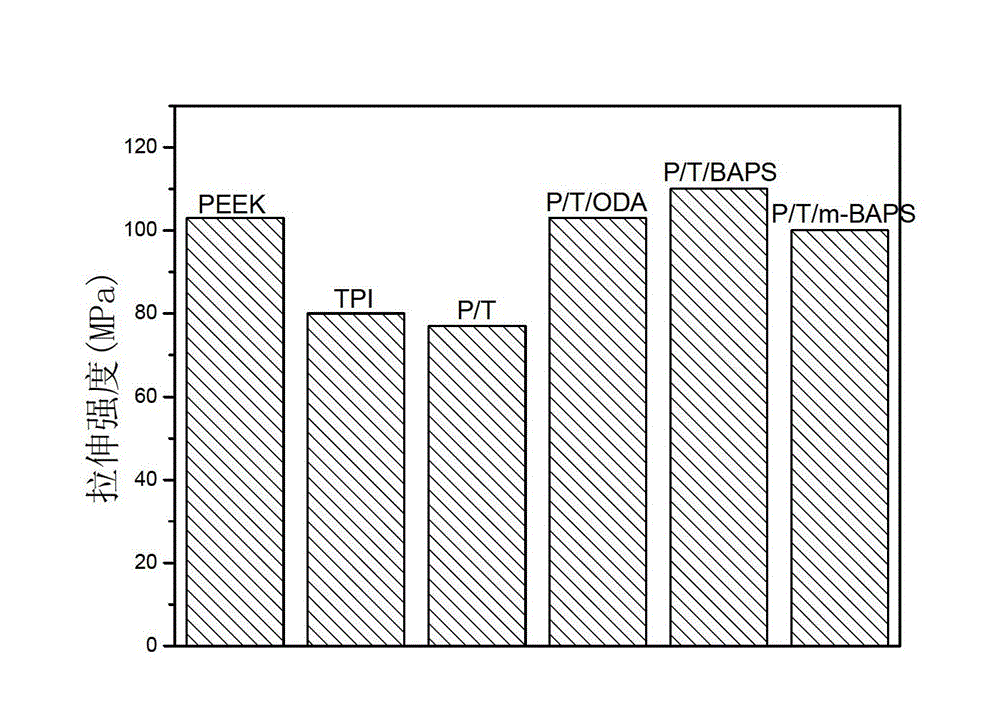

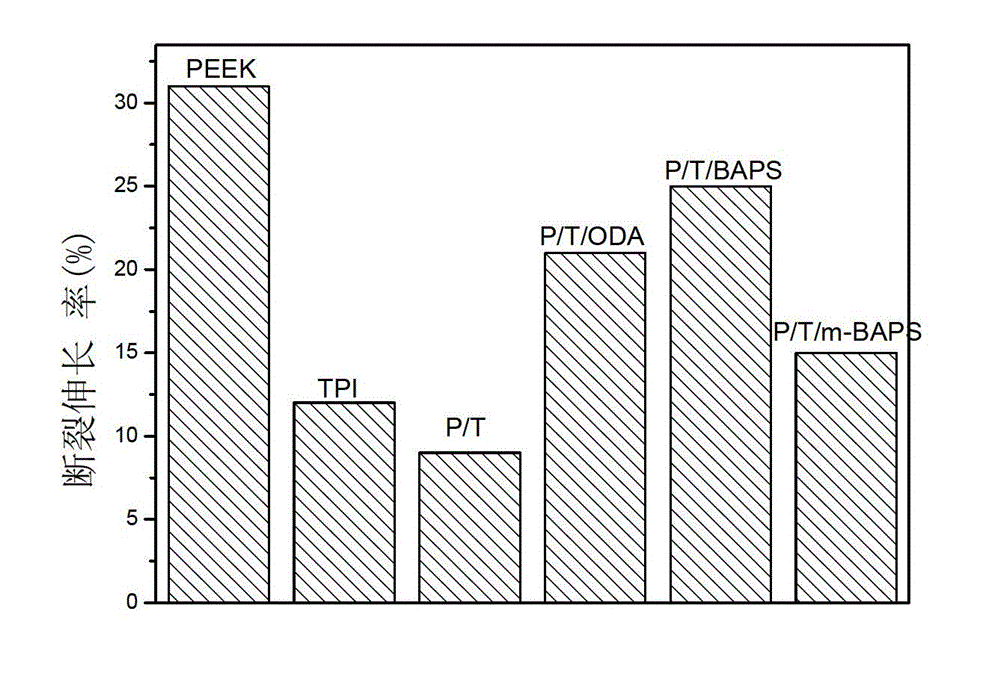

[0042] Take 100g of polyetheretherketone and 100g of thermoplastic polyimide and mix them evenly on a high-speed mixer, add them to the feeding funnel of the twin-screw extruder, then extrude and granulate with the twin-screw extruder to obtain polyether ether ketone: The blend of thermoplastic polyimide with a mass ratio of 50:50 is denoted as P / T.

[0043] The tensile strength of the blend was measured by Shimatsu AG-1 universal testing machine to be 77MPa, and the elongation at break was 9%. The 5% thermal weight loss temperature in air atmosphere was measured by NetzchSta449c thermal analyzer to be 561°C.

[0044] The thermoplastic polyimide used in the present invention is produced by Nanjing Yuezi Chemical Co., Ltd., model YZPI-JL100.

Embodiment 2

[0046] Add 13.08g (0.06mol) of 4,4'-difluorobenzophenone, 5.50g (0.05mol) of resorcinol, carbonic acid Potassium 10.35g (0.075mol) and sulfolane 55g were stirred with nitrogen gas, heated to 150°C for 3 hours to form a salt, and then heated to 240°C for 5 hours to polymerize. Afterwards, the temperature of the reaction system was lowered to 60°C, 2.75g (0.025mol) of p-hydroxyaniline was added, stirred under nitrogen gas, the temperature was raised to 150°C to form a salt for 3 hours, and then the temperature was raised to 180°C for 5 hours to obtain a polymer slime. The polymer slime was cooled to 50°C, crushed, washed with water, and filtered under reduced pressure until the filtrate was colorless and transparent. After drying, 14.86 g of refined amino-terminated polyetheretherketone oligomers were obtained. The molecular weight Mn=3,000 and PDI=1.02 were measured by PL-GPC220 high temperature gel permeation chromatography.

[0047] In a three-neck flask reactor equipped wit...

Embodiment 3

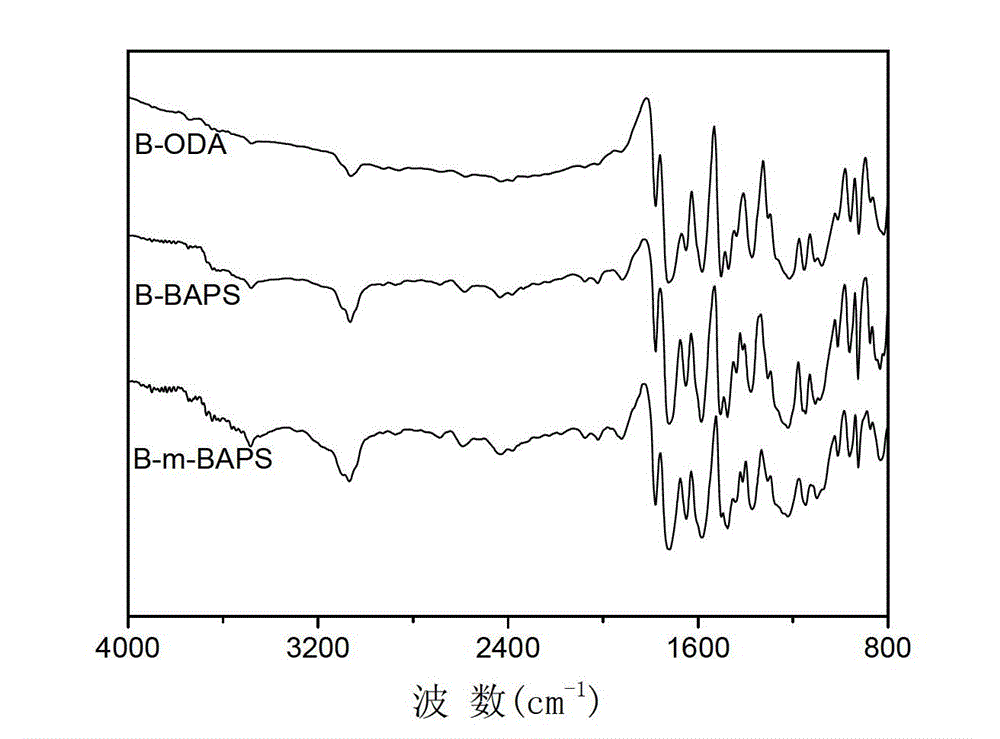

[0052] In a three-neck flask reactor equipped with a stirrer, a drying tube and a nitrogen device, add 4.34 g (0.014 mol) of 4,4'-oxydiphthalic anhydride, 4,4'-bis(4-aminobenzene Oxygen) diphenyl sulfone 3.63g (0.0084mol), N, N- dimethylacetamide 34mL, stirred under nitrogen gas, reacted at 30°C for 8 hours, and obtained acid anhydride-terminated polyimide oligomer mucus, poly The molecular weight Mn=3,000 and PDI=1.04 of the imide oligomer were measured by PL-GPC220 high temperature gel permeation chromatography. 8.73 g of the amino-terminated polyetheretherketone oligomer refined in Example 2 was added thereto, stirred with nitrogen gas, and polymerized at 40° C. for 8 hours. After that, 14 mL of acetic anhydride and 7 mL of triethylamine were added, and the ring was chemically buckled at 100° C. for 8 hours. Pulverize the obtained polymer, boil and wash with water and acetone in turn, and filter under reduced pressure until the filtrate is colorless and transparent. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com