Preparation method of continuous carbon fiber reinforced poly(ether ether ketone) composite material and product

A technology of polyether ether ketone and composite materials, which is applied in the field of fiber-reinforced resin-based composite materials, can solve the problems of polyetheretherketone high melt viscosity and insolubility in any solvent, and achieve high tensile strength, improved mechanical properties, and excellent The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

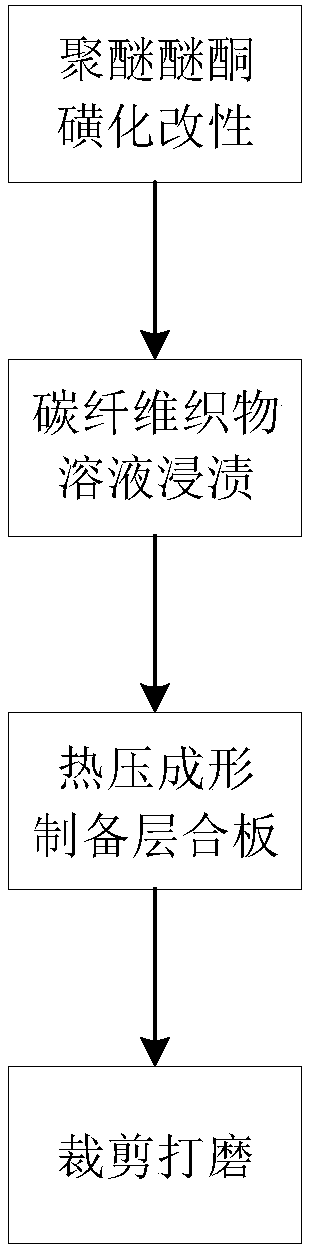

[0027] A preparation method of continuous carbon fiber reinforced polyether ether ketone composite material, comprising the following steps:

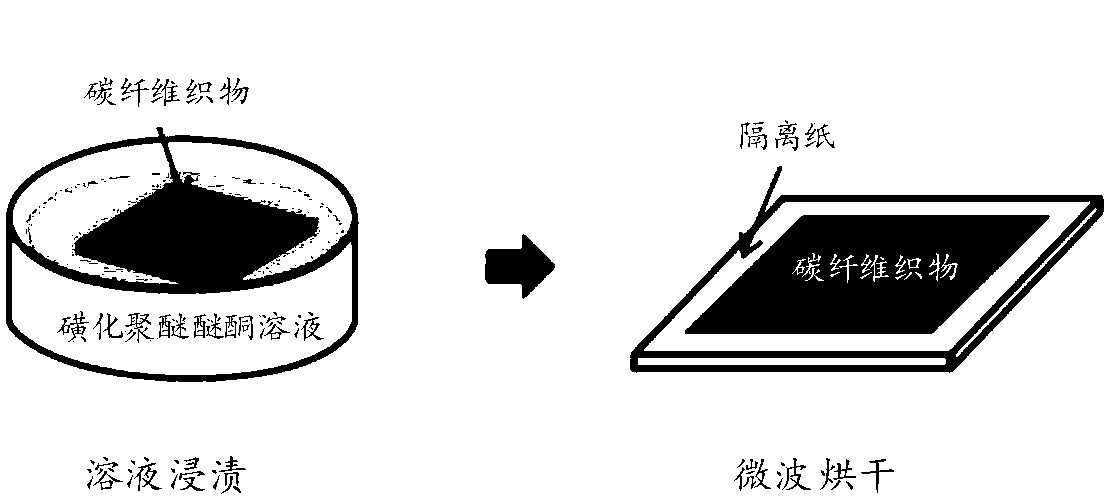

[0028] 1) Preparation of prepreg tape by solution impregnation method: dissolve sulfonated polyether ether ketone powder in an organic solvent, stir continuously to obtain a uniform polymer solution, then place the carbon fiber fabric in the polymer solution, soak it at room temperature for a certain period of time, and take it out , and finally use microwave drying technology to completely volatilize the solvent in the fabric to obtain prepreg products;

[0029] 2) Preparation of carbon fiber-reinforced polyether ether ketone composite material: lay up the prepreg products in step 1 in a certain order and place them in a hot press, heat them to 360-400 ° C, apply a pressure of 1-5 MPa and keep Press for 10 to 20 minutes, cool to room temperature under pressure to obtain a laminated board, and finally cut and polish the laminated board ...

Embodiment 1

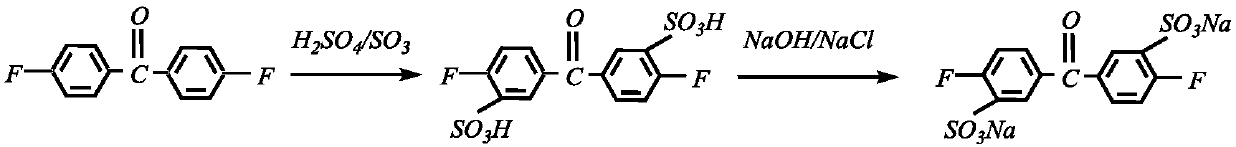

[0041] Add 0.5mol 4,4'-difluorobenzophenone and 300mL 30% oleum into a three-necked flask equipped with mechanical stirring, a thermometer and a reflux condenser in sequence, keep stirring and heat to 110°C for 6h, after cooling Slowly pour into ice water, add sodium hydroxide until the solution is neutral, then add sodium chloride for salting out, filter and dry to obtain sulfonated monomer, and then use methanol aqueous solution for three times of recrystallization to obtain high-purity sulfonated monomer body. Add 30 mmol of sulfonated monomer 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, 70 mmol of non-sulfonated monomer 4,4'-difluorobenzophenone and 100 mmol of bisphenol 3,3',5,5'-Tetramethyl-4,4'-dihydroxybiphenyl was added to a three-necked flask equipped with a mechanical stirrer, a Dean-Stark trap and a nitrogen port, using DMSO as a solvent ( solid content of 20% to 40%), anhydrous potassium carbonate as a catalyst, and toluene as a water-carrying agent, stirre...

Embodiment 2

[0043] Add 20 mmol of sulfonated monomer 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, 80 mmol of non-sulfonated monomer 4,4'-difluorobenzophenone and 100 mmol of bisphenol 3,3',5,5'-Tetramethyl-4,4'-dihydroxybiphenyl was added to a three-necked flask equipped with a mechanical stirrer, a Dean-Stark trap and a nitrogen port, using DMSO as a solvent ( solid content of 20% to 40%), anhydrous potassium carbonate as a catalyst, and toluene as a water-carrying agent, stirred and reacted at 140°C for 3h to remove moisture, then raised the temperature to 170°C for 7h, cooled to room temperature, and poured the reaction mixture into Get flocculent precipitates in water, after pulverization, boil with distilled water and methanol successively, filter to remove inorganic salts and solvents, and finally, dry in a vacuum oven at 100°C for 24 hours to obtain polyether ether ketone with a sulfonation degree of 0.4 , Dissolve the sulfonated polyetheretherketone powder in the organic sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com