Polyaryletherketone composite material and application of the same in bridge bearing

A technology of polyaryletherketone and composite materials, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of poor wear resistance, high friction coefficient of polyaryletherketone, insufficient lubrication, etc., and achieve high wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

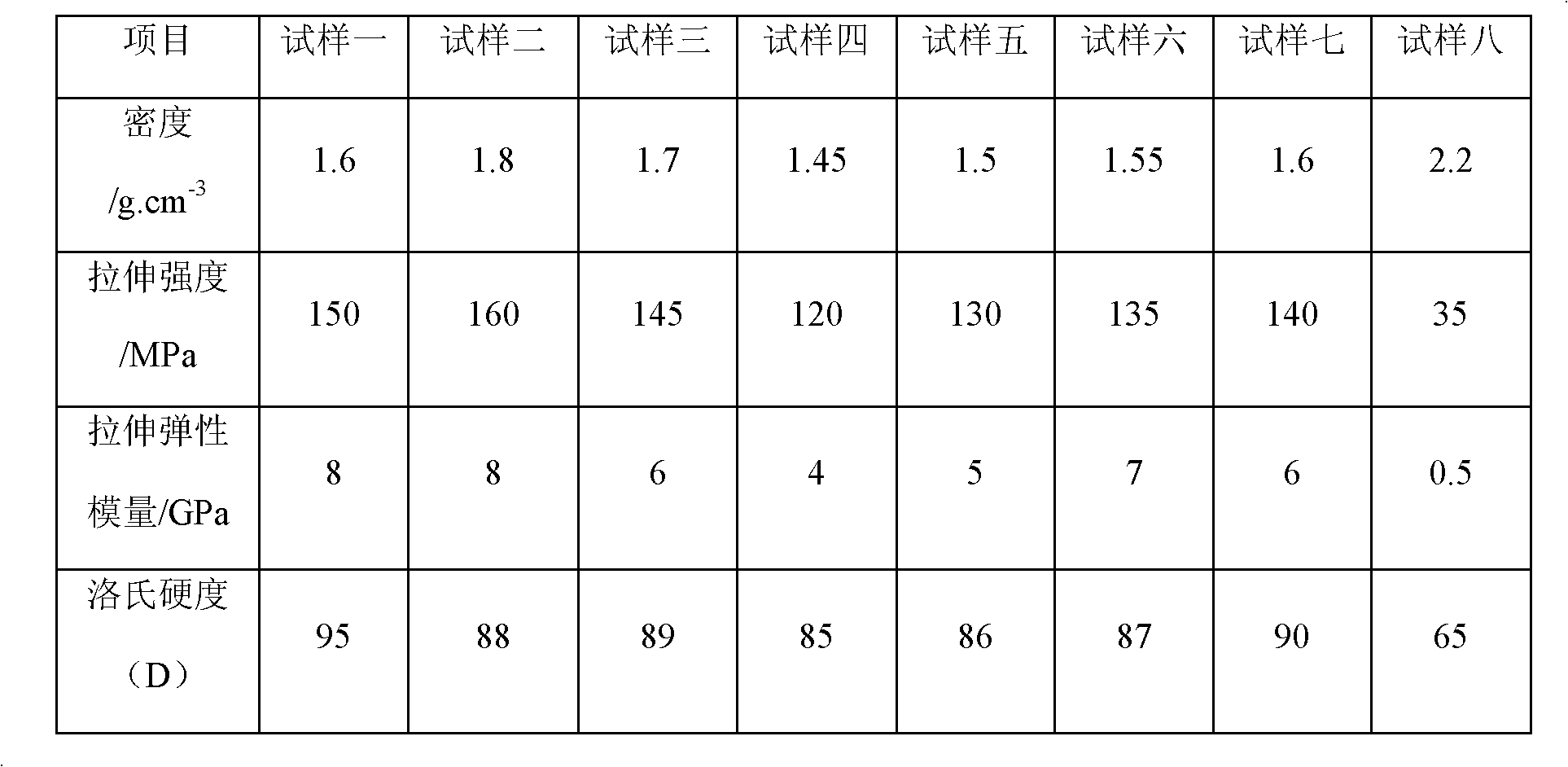

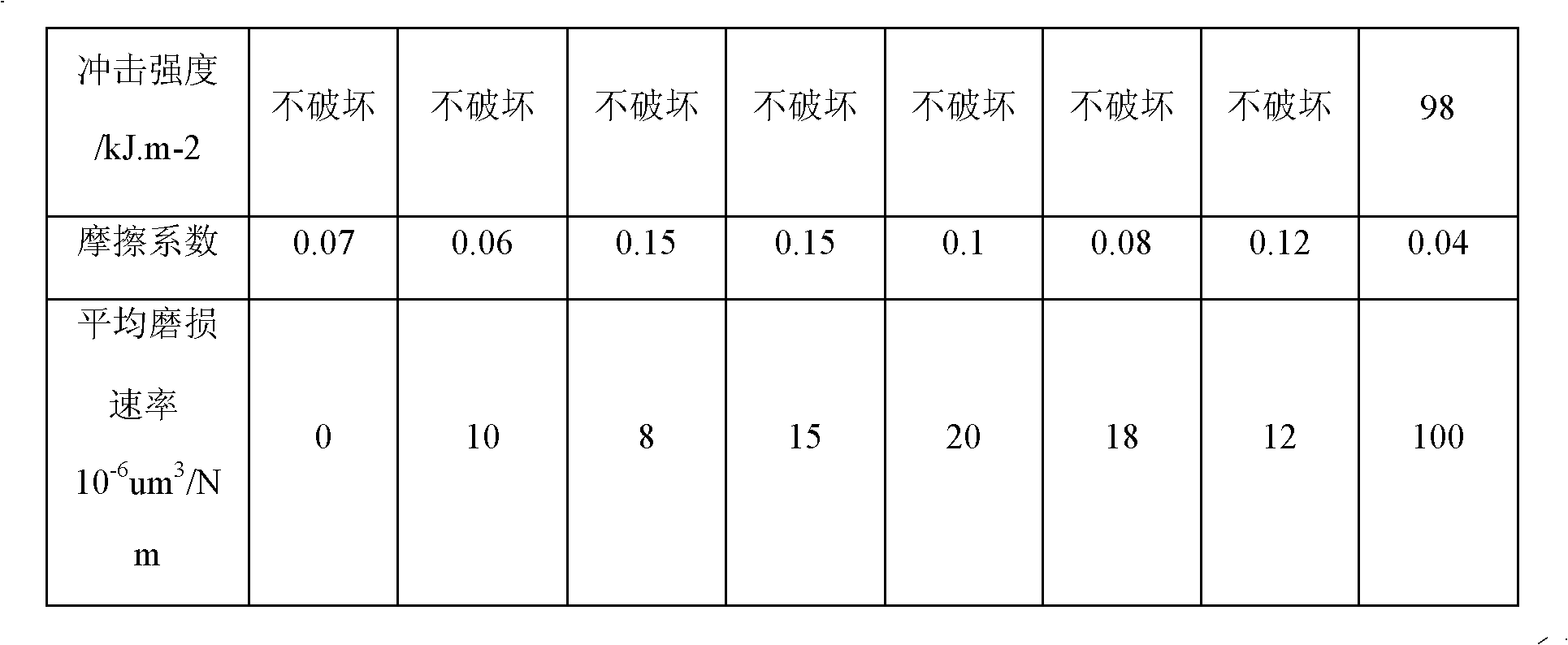

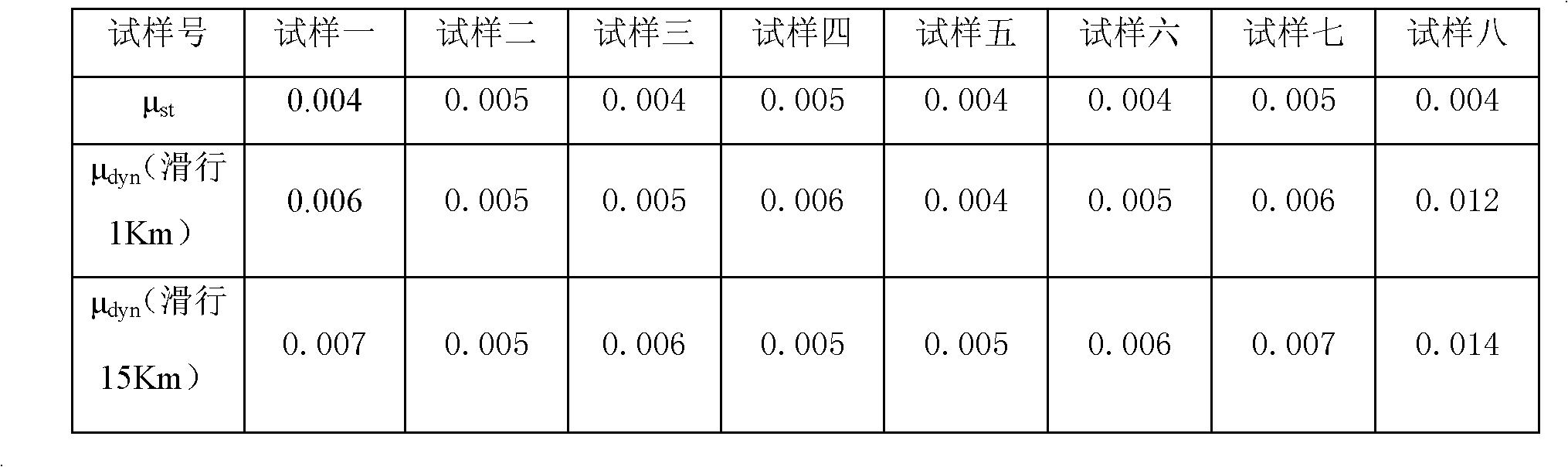

Examples

Embodiment 1

[0021] Get 80 parts of PEEK resin (the density of polyether ether ketone is 1.35g.cm -3 , the size is less than 100um), 5 parts of polytetrafluoroethylene powder, 5 parts of carbon fiber, graphite fiber or silicon carbide fiber (the average diameter of carbon fiber is 100um, the length is 20mm, and the density is 1.67g.cm -3 ), 9 parts of molybdenum disulfide, graphite or carbon powder, 1 part of tin bronze alloy, these materials are fully pre-mixed and stirred by a mechanical mixer; then processed by ball milling, fully dispersed and mixed evenly, and then put into an oven , to dry, remove the moisture of the mixture, and dry at 130°C for 3 hours; put the above powder into the mold, pressurize to 1MPa, wait for the temperature to rise to 340°C, and keep the temperature for 15min. During the above molding process, Deflate every 5 minutes. Continue to raise the temperature to 400°C, and slowly increase the pressure. When the pressure reaches 5MPa, keep it under this pressure f...

Embodiment 2

[0023] Get 50 parts of PEEKK resin (the density of polyether ether ketone ketone is 1.36g.cm -3 ), the size is less than 200um, 20 parts of polytetrafluoroethylene powder, 20 parts of glass fiber, 15 parts of nano-diamond powder or niobium diselenide, 15 parts of calcium carbonate or calcium sulfate, and fully premix these materials with a mechanical mixer Stir; then use the method of ball milling to process, fully disperse and mix evenly, then put it in an oven, and dry it to remove the moisture of the mixture. The drying condition is 135°C for 3 hours; 1.5MPa, when the temperature rises to 350°C, keep the temperature constant for 15 minutes, during the above molding process, deflate once every 5 minutes. Continue to raise the temperature to 400°C, and slowly increase the pressure. When the pressure reaches 5MPa, keep it under this pressure for 40 minutes, cool down to 150°C at a speed of 50°C / min, and keep it warm for 1 hour for post-treatment to eliminate internal stress. ...

Embodiment 3

[0025] Take 70 parts of PEK or polyetheretherketone raw materials, 2 parts of Kevlar, Nomex or PBI fiber, 27 parts of molybdenum disulfide, quartz powder or boron nitride, and 1 part of carbon black, and fully pre-mix these materials with a mechanical mixer Stir; then use the method of ball milling to process, fully disperse and mix evenly, then put it in an oven, and carry out drying treatment to remove the moisture of the mixture, and the drying condition is 150°C for 3 hours; put the above powder into the mold, pressurize to 3MPa, wait for the temperature to rise to 360°C, and keep the temperature constant for 12 minutes. During the above molding process, deflate once every 5 minutes. Continue to heat up to 420°C, and slowly increase the pressure. When the pressure reaches 10MPa, keep it under this pressure for 60 minutes, cool down to 200°C at a speed of 20°C / min, and keep it warm for 1 hour for post-treatment to eliminate internal stress. The mold temperature is lowered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com