Epoxy crosslinking sulfonated polyaryletherketone proton exchange membrane material and preparation method thereof

A technology of sulfonated polyaryletherketone and proton exchange membrane, which is applied in chemical instruments and methods, membrane technology, fuel cells, etc., can solve the problems of increased methanol penetration, reduced mechanical properties, and dissolution, and achieves alcohol resistance and Improved temperature resistance, simple operation, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

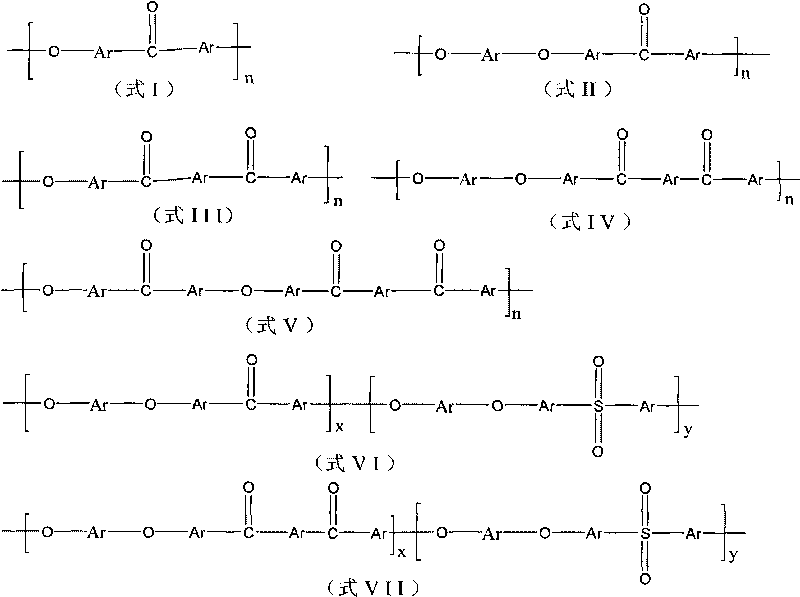

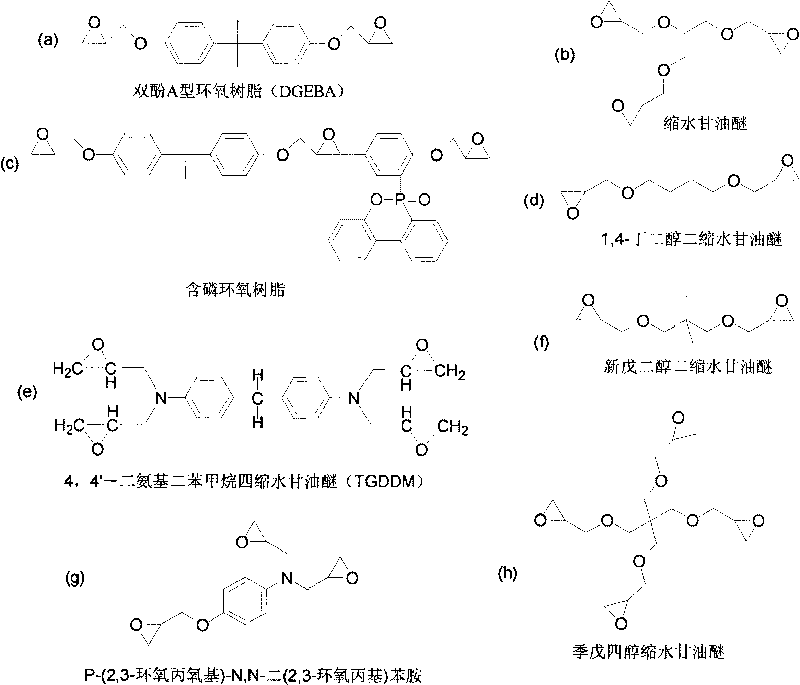

[0029]Get the sulfonated polyether ketone (the structural formula of described polyether ketone is as shown in formula I, wherein n=350) that the degree of sulfonation is 75%, use 1mol / L Na 2 CO 3 The solution was soaked for 24 hours, washed with deionized water until neutral and dried in vacuum, dissolved in a mixture of ethanol and water with a volume ratio of 1:1, and prepared as a solution with a percentage of 15wt%; weighed 100 parts of polymer Solution, start stirring, under the protection of inert gas, slowly add 10 parts of 10wt% sodium borohydride aqueous solution at 25 ° C, keep the reaction system at 80 ° C and continue to react for 24 hours, after filtration, concentrate the filtrate and vacuum dry to obtain hydroxyl Functionalized sulfonated polyether ketone; the dried reduction product is dissolved in dimethylformamide, and prepared into a solution with a mass percentage of 10 wt%. Take 100 parts of hydroxyl functionalized sulfonated polyether ketone solution wi...

Embodiment 2

[0031] Take sulfonated polyether ether ketone (the structural formula of the polyether ether ketone is shown in formula II, wherein n=300) with a sulfonation degree of 65%, and use 1mol / L Na 2 CO 3 The solution was soaked for 24 hours, washed with deionized water until neutral and dried in vacuum, dissolved in a mixture of methanol and water with a volume ratio of 1:1, and prepared as a 15wt% solution; weighed 100 parts of polymer Solution, start stirring, under the protection of inert gas, slowly add 10 parts of 10wt% sodium borohydride aqueous solution at 25 ° C, keep the reaction system at 80 ° C and continue to react for 24 hours, filter and concentrate the filtrate and vacuum dry to obtain Hydroxyl-functionalized sulfonated polyether ether ketone; the dried reduction product is dissolved in dimethylformamide, and prepared into a solution with a mass percentage of 10 wt%. Take 100 parts of hydroxyl-functionalized sulfonated polyetheretherketone solution with a percentage ...

Embodiment 3

[0033] Get the sulfonated polyether ketone ketone (the structural formula of described polyether ketone ketone is shown in formula III, wherein n=260) that sulfonation degree is 84%, use 1mol / L Na 2 CO 3 The solution was soaked for 24 hours, washed with deionized water until neutral and dried in vacuum, dissolved in a mixture of methanol and water with a volume ratio of 1:1, and prepared as a 15wt% solution; weighed 100 parts of polymer solution, start stirring, under the protection of an inert gas, slowly add 15 parts of 10wt% sodium borohydride aqueous solution at 25°C, keep the reaction system at 80°C and continue to react for 24 hours, after filtering, concentrate the filtrate and vacuum dry to obtain Hydroxyl-functionalized sulfonated polyether ketone ketone; the dried reduction product is dissolved in dimethylformamide, and prepared into a solution with a mass percentage of 10 wt%. Take 100 parts of hydroxyl functionalized sulfonated polyether ketone ketone solution wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com