Preparation of capsules

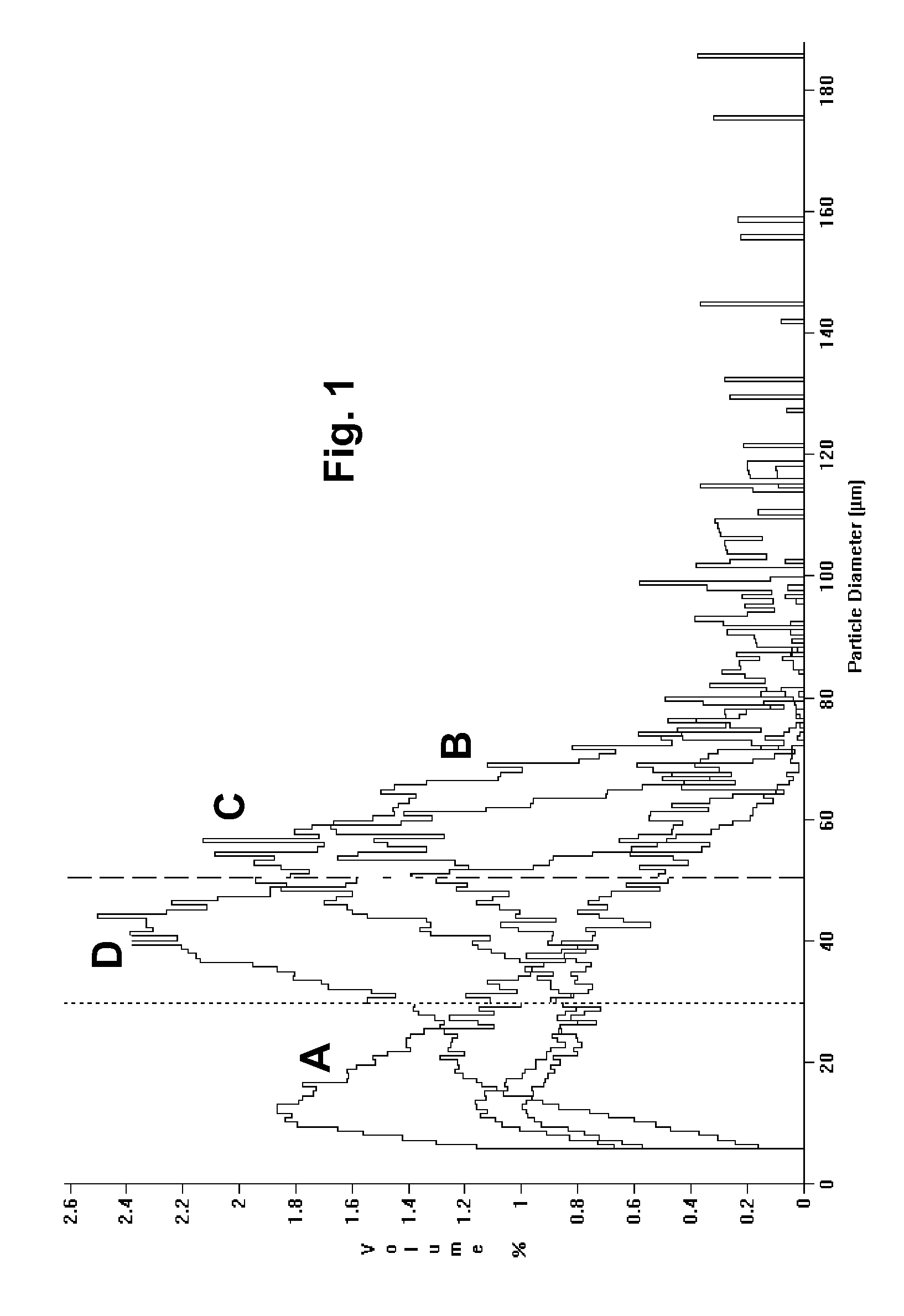

a technology of capsules and encapsulation processes, applied in colloidal chemistry, packaged goods types, instruments, etc., can solve the problems of inadequate service life of these displays, and low yield of capsules with the desired diameter rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055] An internal phase was prepared substantially as described in the aforementioned 2002 / 0180687, this internal phase comprising polymer-coated titania and polymer-coated carbon black in a hydrocarbon solvent. This internal phase was then encapsulated by both a prior art (“PA”) process and a preformed coacervate process (“PC”) of the present invention. The material amounts given for the PC process are for a scaled down volume of 75%, based on water and oil amounts, of the original PA process. The material and amounts used for the two encapsulations were are shown in Table 1 below:

TABLE 1MaterialPAPCDeionized water3277618437Gelatin667300Makeup water06145Acacia667300Internal Phase107008025Glutaraldehyde16787.7

[0056] The encapsulations were performed in a 50 L reactor provided with a propeller type stirrer. The prior art process was carried out substantially as described in the aforementioned 2002 / 0180687. The gelatin was added to the deionized water in the reactor and the mixture...

example 2

[0071] Two identical internal phases were prepared each comprising 42.5 g of a 60 weight percent suspension of a polymer-coated copper chromite pigment in Isopar E (a hydrocarbon solvent available from Exxon Corporation, Houston Tx.; ISOPAR is a Registered Trade Mark), 85 g of a 60 weight percent suspension of a polymer-coated titania pigment in Isopar E, 10.71 g of a solution of Solsperse 17K in Isopar G (a hydrocarbon solvent from the same manufacturer as Isopar E), 0.77 g of Span 80 (a surfactant available from Aldrich Chemical Corporation), and 31.03 g of additional Isopar E.

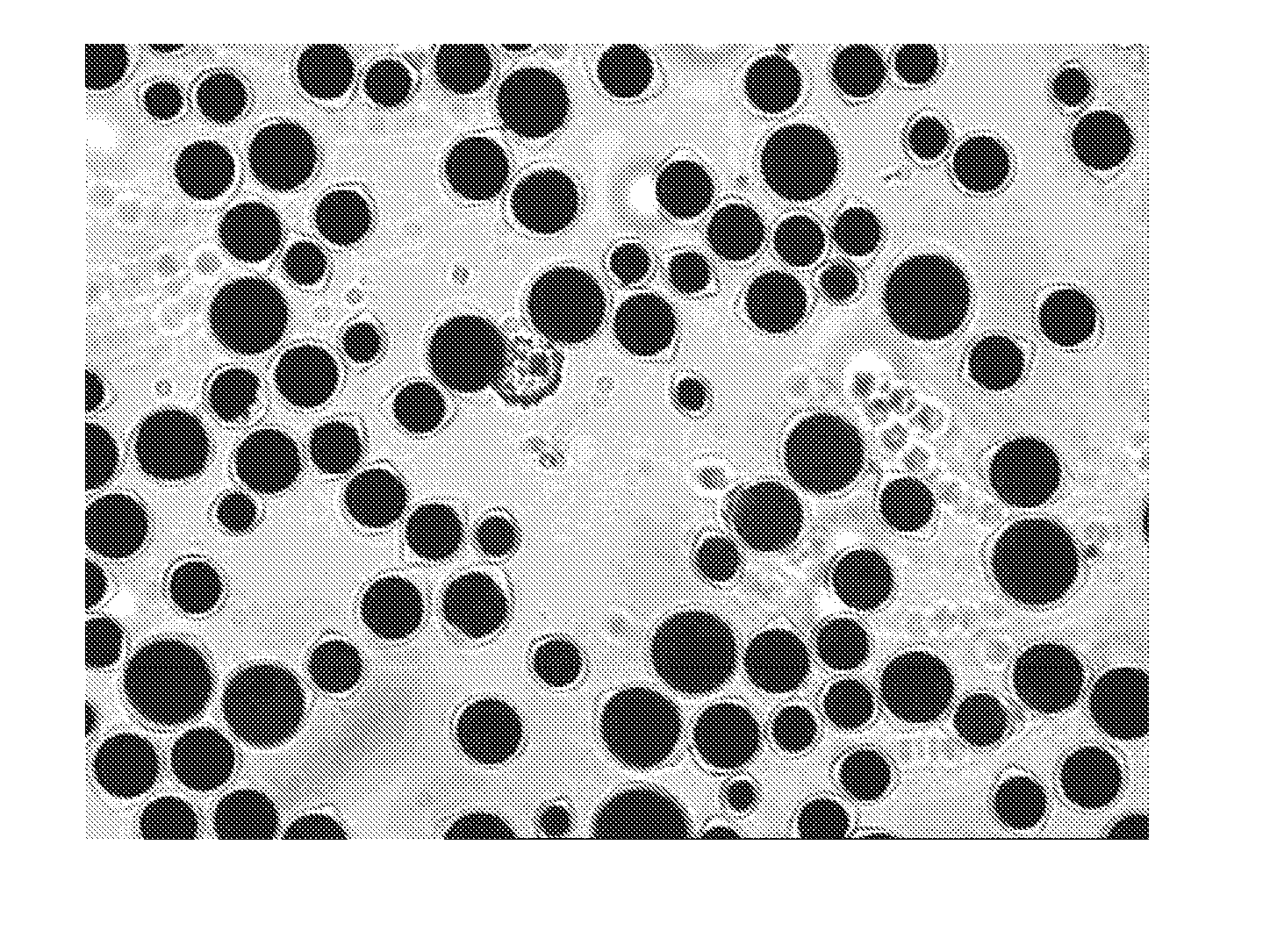

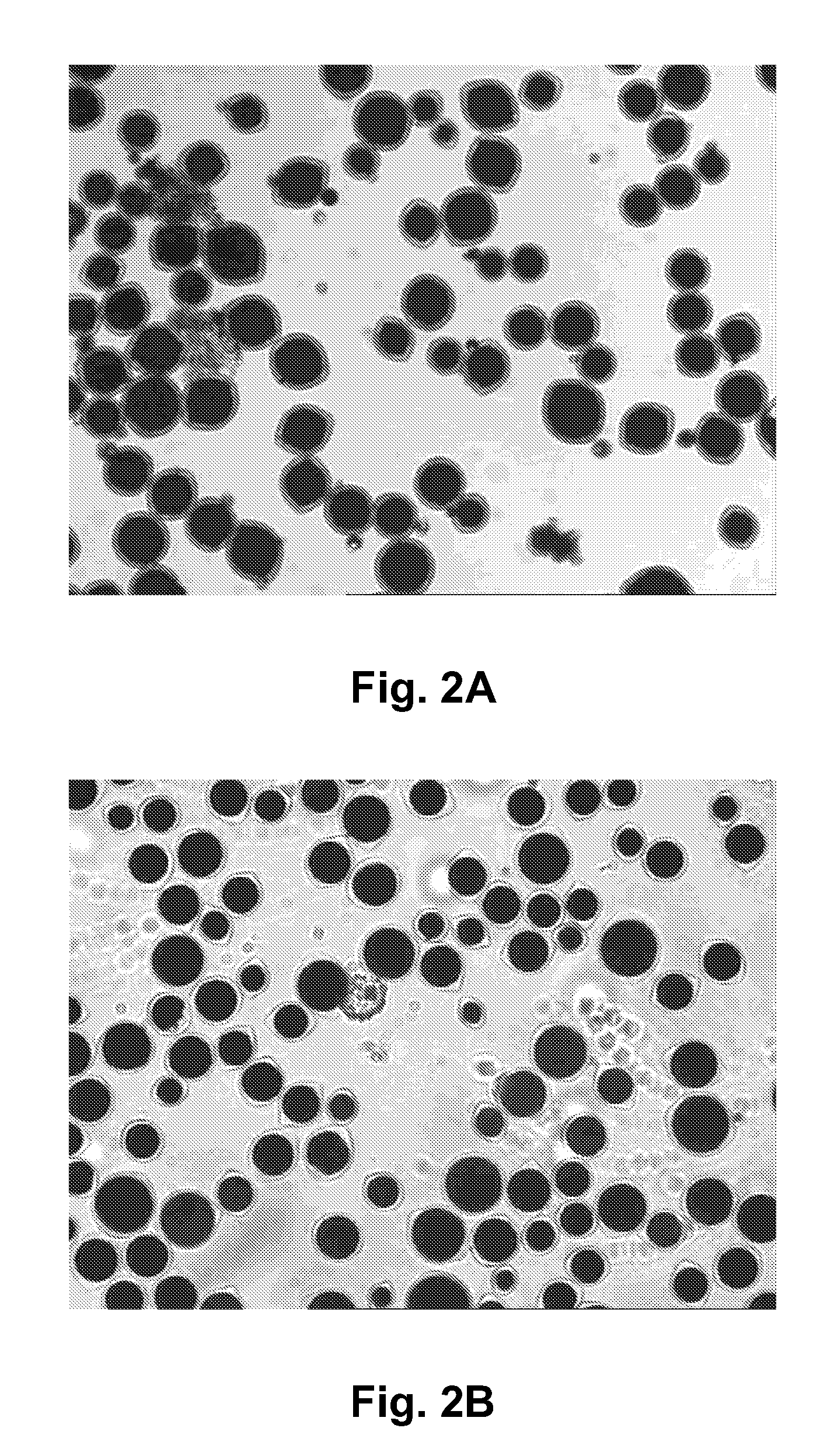

[0072] One of internal phases was used in a control experiment using a prior art encapsulation process substantially as described in the aforementioned 2002 / 0180687. The emulsification step was carried out by addition of the 140 mL internal phase to a solution of 10 g of gelatin in 240 g water at 42.5° C., and agitating the resulting mixture with a 2 inch (51 mm) prop impeller at 650 rpm for one hour. By th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com