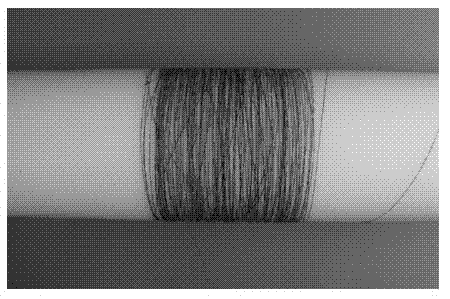

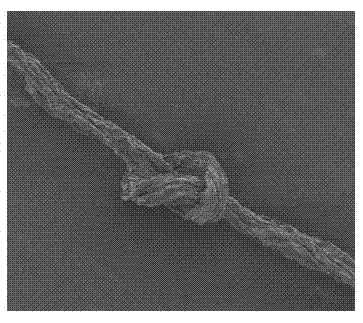

Preparation method for high strength macro graphene conductive fiber

A conductive fiber, graphene technology, applied in the chemical characteristics of fibers, textiles and papermaking, chemical post-processing of rayon, etc., can solve the problems such as the failure of macroscopic graphene fibers to achieve, achieve good strength and toughness, excellent electrical conductivity, The effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of high-strength macro graphene conductive fiber of the present invention comprises the following steps:

[0020] 1. Mix 1 part by weight of graphite raw material, 1-100 parts by weight of sulfuric acid, 0.5-5 parts by weight of potassium persulfate and 0.5-5 parts by weight of phosphorus pentoxide, and stir and react at 25-100 °C for 1-10 hours. After cooling to room temperature, dilute with deionized water, filter with filter membrane, wash with deionized water until neutral, and dry naturally for 10-50 hours to obtain intercalated graphite.

[0021] Graphite is natural graphite or pyrolytic graphite, and sulfuric acid is sulfuric acid with a mass concentration greater than 80%.

[0022] 2. Mix 1 part by weight of the intercalated graphite obtained in step 1, 1~100 parts by weight of sulfuric acid and 0.5~10 parts by weight of potassium permanganate, stir and react at -10~50°C for 0.1~10 hours, then add 10 ~2000 parts by weight of deionized wat...

Embodiment 1

[0035] Step (a): Add 10g of graphite, 10g of 90% sulfuric acid, 1g of potassium persulfate and 1g of phosphorus pentoxide into the reaction flask, stir and react at 80°C for 5 hours, cool to room temperature, and rinse with deionized water Dilute, filter with filter membrane, wash the filter cake repeatedly with deionized water until neutral, dry naturally for 10 hours to obtain intercalated graphite;

[0036] Step (b): Add 5g of the intercalated graphite product obtained in step (a), 20g of 80% sulfuric acid and 2.5g of potassium permanganate to the reaction bottle, stir and react at 50°C for 2 hours, then add 1kg of deionized Water and 0.5g of 30% hydrogen peroxide were stirred for 10 hours, filtered through a filter membrane, and the filter cake was repeatedly washed with deionized water to neutrality, and dried naturally to obtain preliminary graphite oxide;

[0037] Step (c): Add 2g of the preliminary graphite oxide product obtained in step (b), 20g of 90% sulfuric acid, ...

Embodiment 2

[0043] Step (a): Add 10g of graphite, 100g of 90% sulfuric acid, 50g of potassium persulfate and 50g of phosphorus pentoxide into the reaction flask, stir and react at 80°C for 5 hours, cool to room temperature, and use deionized Dilute with water, filter with filter membrane, wash the filter cake repeatedly with deionized water until neutral, dry naturally for 10 hours to obtain intercalated graphite;

[0044] Step (b): Add 5g of the intercalated graphite product obtained in step (a), 300g of 90% sulfuric acid and 50g of potassium permanganate into the reaction bottle, stir and react at 50°C for 2 hours, then add 1kg of deionized water Stir with 30% hydrogen peroxide of 30g for 10 hours, filter with filter membrane, wash the filter cake repeatedly with deionized water to neutrality, and dry naturally to obtain preliminary graphite oxide;

[0045] Step (c): Add 2g of the preliminary graphite oxide product obtained in step (b), 300g of 90% sulfuric acid, 20g of potassium perman...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com