Heat-resistant epoxy anhydride resin suitable for vacuum pressure impregnation (VPI) and preparing method and application thereof

A technology of epoxy resin and heat-resistant resin, used in epoxy resin coatings, plastic/resin/wax insulators, coil manufacturing, etc., can solve problems such as poor insulation performance of products, achieve fast curing speed, good heat resistance, Conducive to environmental protection and the health of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 is suitable for the preparation of the epoxy anhydride heat-resistant resin of heating VPI

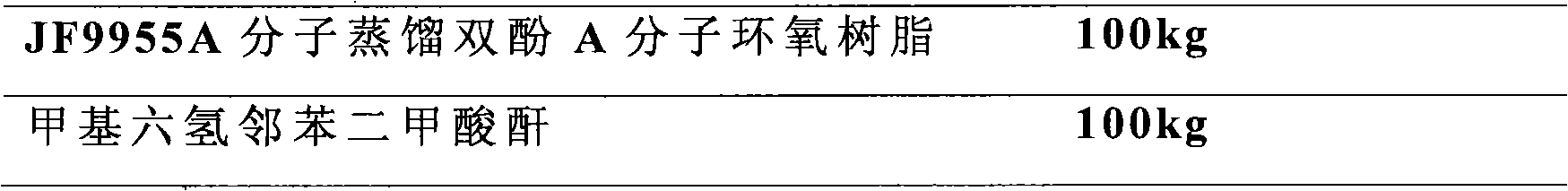

[0028] The composition of the epoxy anhydride heat-resistant resin suitable for heating VPI is as follows:

[0029]

[0030] Preparation of raw materials:

[0031] Among them, 100 kg of JF9955A molecularly distilled bisphenol A molecular epoxy resin is hot-melted and added to the reaction kettle for stirring, vacuum dehumidification for 0.5h, the material is stirred evenly, filtered, and individually sealed and packaged. Add 100 kg of methylhexahydrophthalic anhydride into the reaction kettle, stir evenly, vacuum dehumidify for 0.5h, filter, and pack in a separate airtight package.

[0032] Raw material storage:

[0033] JF9955A molecularly distilled bisphenol A molecular epoxy resin and methyl hexahydrophthalic anhydride are packaged and stored separately. The storage period of each component in an airtight container below 20°C is ≥12 months. This method is su...

Embodiment 2

[0036] Embodiment 2 is suitable for the preparation of the epoxy anhydride heat-resistant resin of heating VPI

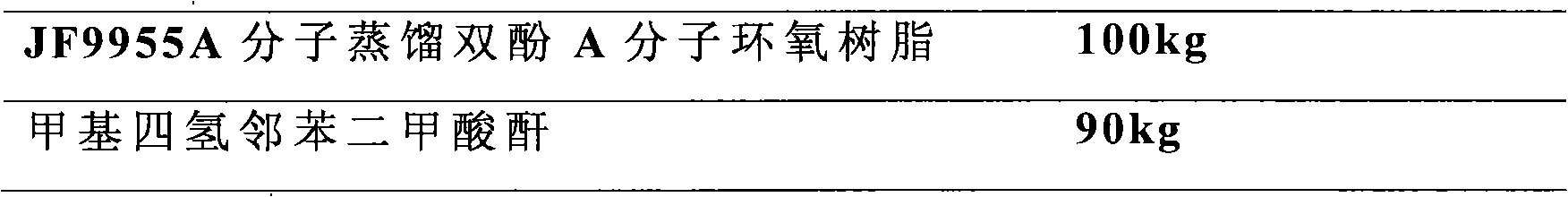

[0037] The composition of the epoxy anhydride heat-resistant resin suitable for heating VPI is as follows:

[0038]

[0039] Preparation of raw materials:

[0040] Among them, 100 kg of JF9955A molecularly distilled bisphenol A molecular epoxy resin is hot-melted and added to the reaction kettle for stirring, vacuum dehumidification for 0.5h, the material is stirred evenly, filtered, and individually sealed and packaged. Add 90 kg of methyltetrahydrophthalic anhydride into the reaction kettle, stir evenly, vacuum dehumidify for 0.5h, filter, and pack separately.

[0041] Raw material storage:

[0042] JF9955A molecularly distilled bisphenol A molecular epoxy resin and methyltetrahydrophthalic anhydride are packaged and stored separately. The storage period of each component in an airtight container below 20°C is ≥12 months. This method is suitable for heating...

Embodiment 3

[0045] Embodiment 3 is suitable for the preparation of the epoxy anhydride heat-resistant resin of heating VPI

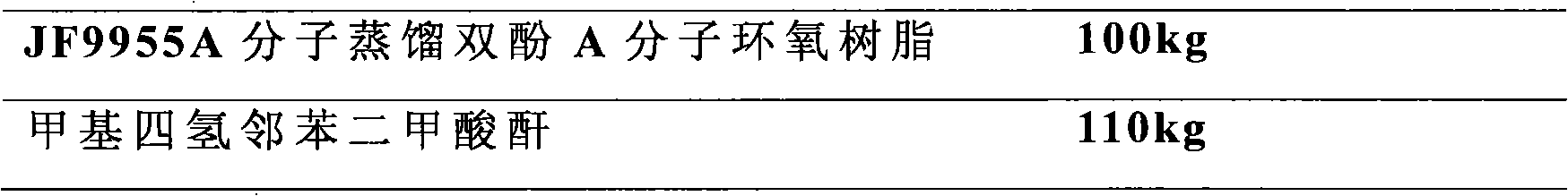

[0046] The composition of the epoxy anhydride heat-resistant resin suitable for heating VPI is as follows:

[0047]

[0048] Preparation of raw materials:

[0049] Among them, 100 kg of JF9955A molecularly distilled bisphenol A molecular epoxy resin is hot-melted and added to the reaction kettle for stirring, vacuum dehumidification for 0.5h, the material is stirred evenly, filtered, and individually sealed and packaged. Add 110 kg of methyltetrahydrophthalic anhydride into the reaction kettle, stir evenly, dehumidify in vacuum for 0.5 h, filter, and pack in a separate airtight package.

[0050] Storage method, resin preparation method are similar to embodiment 1,2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com