Polysiloxane-allyl compound modified polyphenylene ether resin composition, and prepreg, laminated board and printed circuit board thereof

An allyl compound, polyphenylene ether resin technology, applied in synthetic resin layered products, printed circuits, printed circuits, etc., can solve the problem of poor adhesion between the composition and metal foil, low dielectric constant, low dielectric Loss factor etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

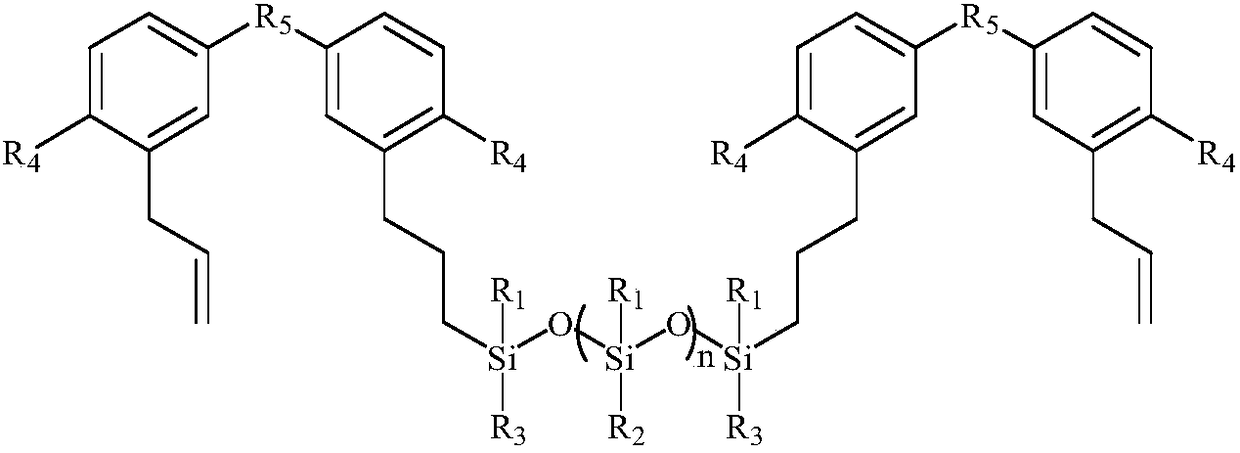

[0075] In this example, the polysiloxane-allyl compound shown in formula I was prepared from 2,2'-diallyl bisphenol A and hydrogen-containing polysiloxane HWG17606 through hydrosilylation, and the preparation method was as follows :

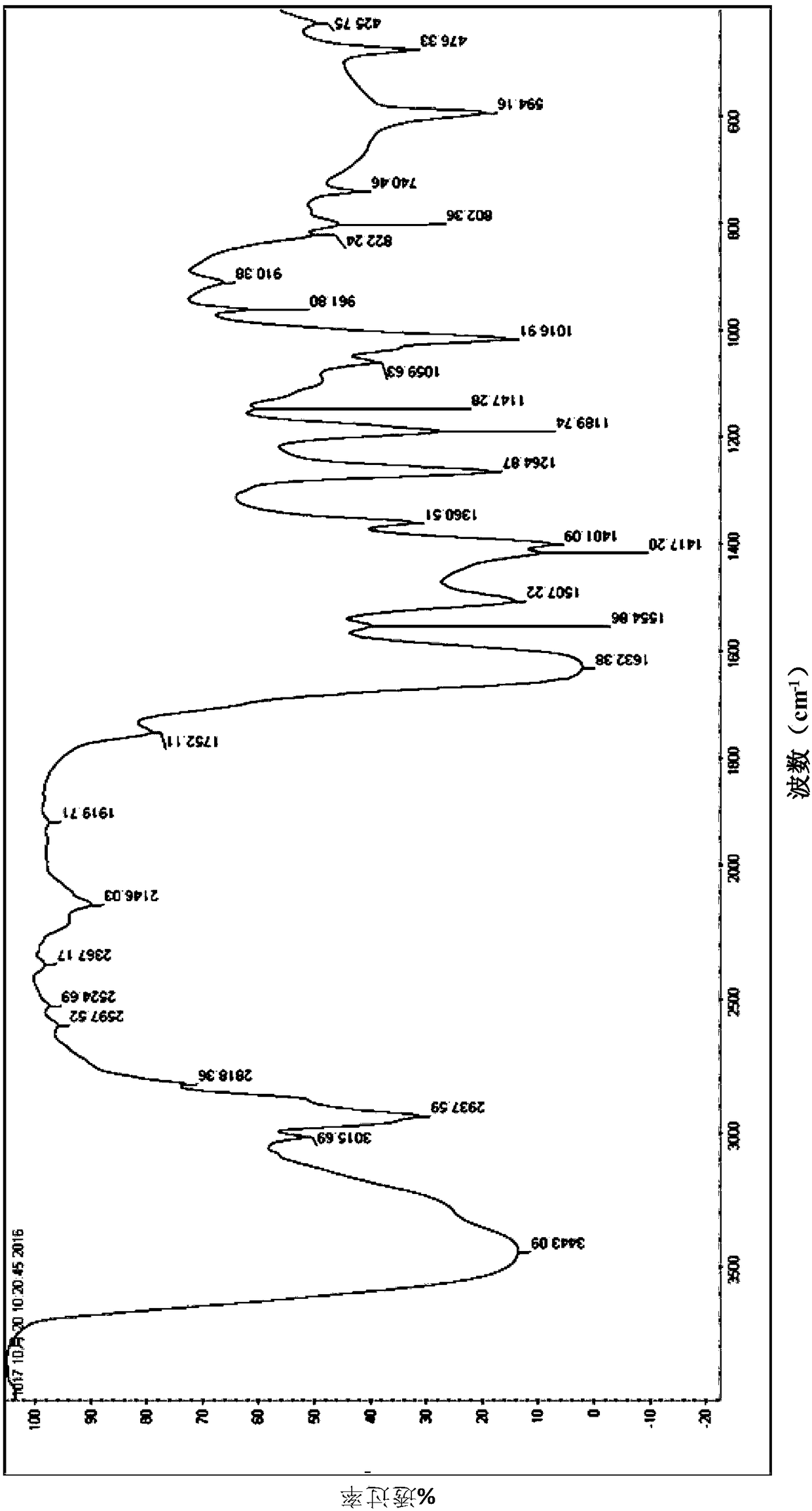

[0076] Dissolve diallyl bisphenol A and catalyst chloroplatinic acid completely with an appropriate amount of toluene, mix them, preheat to 60°C, add metered amount of hydrogen-containing polysiloxane drop by drop under constant stirring in a nitrogen atmosphere, and continue React until the signal peak (near 2145cm-1) of the Si-H bond in the infrared spectrum of the reaction mixture solution disappears or is very weak, while the allyl group signal peak (near 1635cm-1) remains strong, stop heating, and depressurize The solvent is removed to obtain a polysiloxane-allyl compound, the structure of which is shown in formula d.

[0077] The infrared spectrum characterization results of the prepared polysiloxane-allyl compound are as follows: figure ...

Embodiment 2

[0081] In this example, the polysiloxane shown in formula I was prepared from 3,3'-diallyl-4,4'diphenol ether diglycidyl ether and hydrogen-containing polysiloxane HWG17606 by hydrosilylation - allyl compound, the preparation method is as follows:

[0082] Completely dissolve 3,3'-diallyl-4,4'diphenol ether diglycidyl ether and 10ppm Karstd catalyst with an appropriate amount of toluene, mix, preheat to 70°C, and keep stirring in a nitrogen atmosphere Add the metered amount of hydrogen-containing polysiloxane dropwise, and continue the reaction until the signal peak (2145cm) of the Si-H bond in the infrared spectrum of the reaction mixture solution -1 near) disappeared or very weak, while the allyl group signal peak (1635cm -1 Nearby) still remain strong, stop heating, remove solvent under reduced pressure, obtain polysiloxane-allyl compound, its structure is shown in formula a.

[0083] Dissolve MX9000 and the compound of formula a prepared above with an appropriate amount ...

Embodiment 3

[0086] In this example, the polymer shown in Formula I was prepared from 1,1-bis(3,3'-diallyl-4,4'xylene)methane and hydrogen-containing polysiloxane HWG17606 through hydrosilylation. Siloxane-allyl compound, the preparation method is as follows:

[0087] Completely dissolve 1,1-bis(3,3'-diallyl-4,4'xylene)methane and 10ppm of Karstd catalyst with an appropriate amount of toluene, mix, preheat to 85°C, and place in a nitrogen atmosphere without Stop stirring and add metered amount of hydrogen-containing polysiloxane dropwise, and continue the reaction until the signal peak (near 2145cm-1) of the Si-H bond in the infrared spectrum of the reaction mixture solution disappears or is very weak, while the allyl group signal The peak (near 1635cm-1) still remained strong, the heating was stopped, and the solvent was removed under reduced pressure to obtain a polysiloxane-allyl compound, the structure of which was shown in formula b.

[0088] Dissolve MX9000 and the compound of formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com