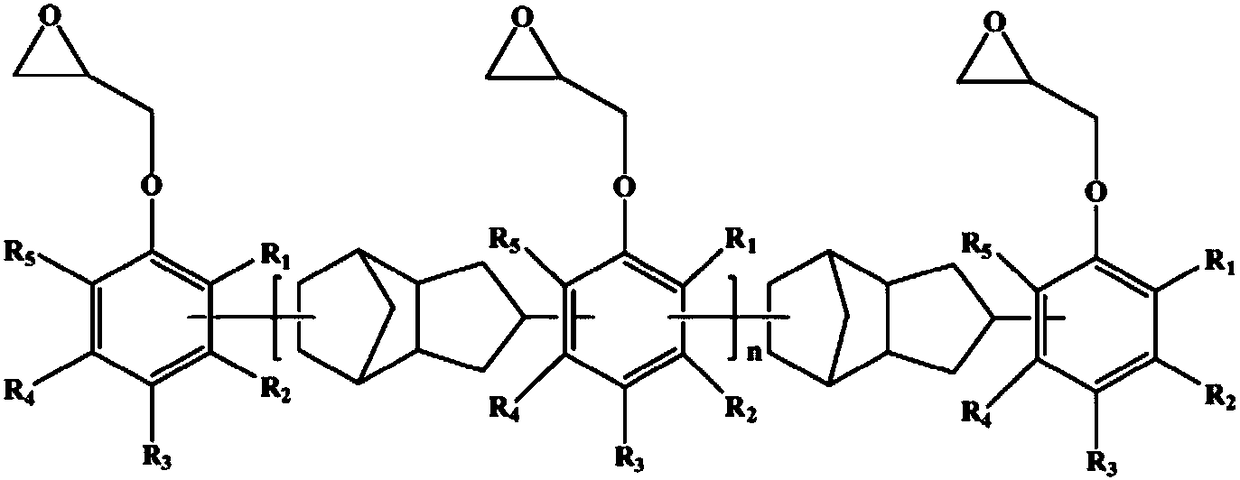

Epoxy resin containing TCPD structure, epoxy resin composition, prepreg, laminated board and printing circuit board

A technology of epoxy resin and novolac epoxy resin, which is applied in the field of laminates, can solve the problems of low dielectric constant, heat resistance to be further improved, low dielectric loss factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

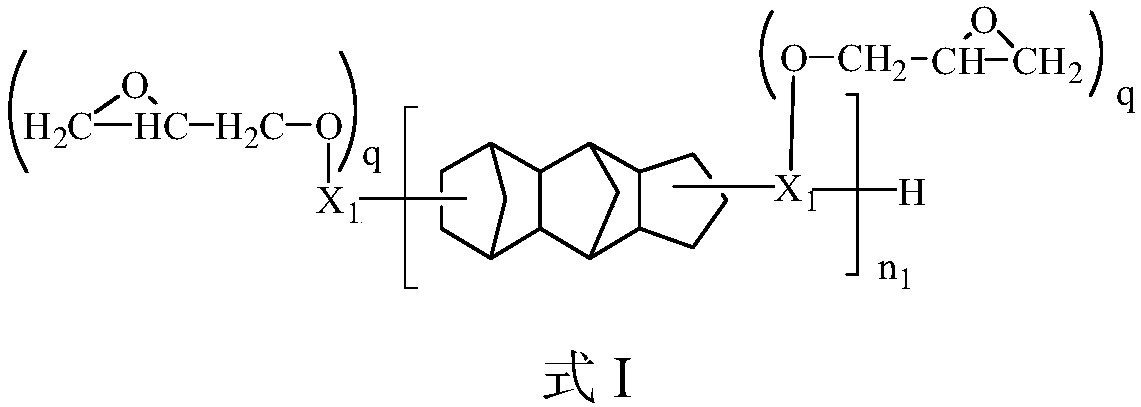

[0099] Preparation example 1: the synthesis of the epoxy resin of formula I structure

[0100] Add 54.4g of phenol and toluene into a four-necked flask (500mL) equipped with a stirrer, a thermometer, and a condensing reflux device, dissolve in a water bath, weigh 1.4g of boron trifluoride diethyl ether complex, and add In the flask, add 39.6g TCPD into the dropping funnel, control the dropping speed so that all the TCPD is added dropwise within 2 hours, raise the temperature to 100-120°C, keep it warm for 5 hours, after the reaction is over, wash with water, filter, recrystallize, vacuum Dry to obtain the phenolic resin containing TCPD structure.

[0101] Put the 25g phenolic resin containing the TCPD structure obtained in the previous step into a four-necked flask, then weigh 100g epichlorohydrin and add slowly, after it dissolves, start to heat up, and add 1mol of mass fraction in the dropping funnel to be 33% NaOH solution, control the speed so that it can be added dropwis...

preparation example 2

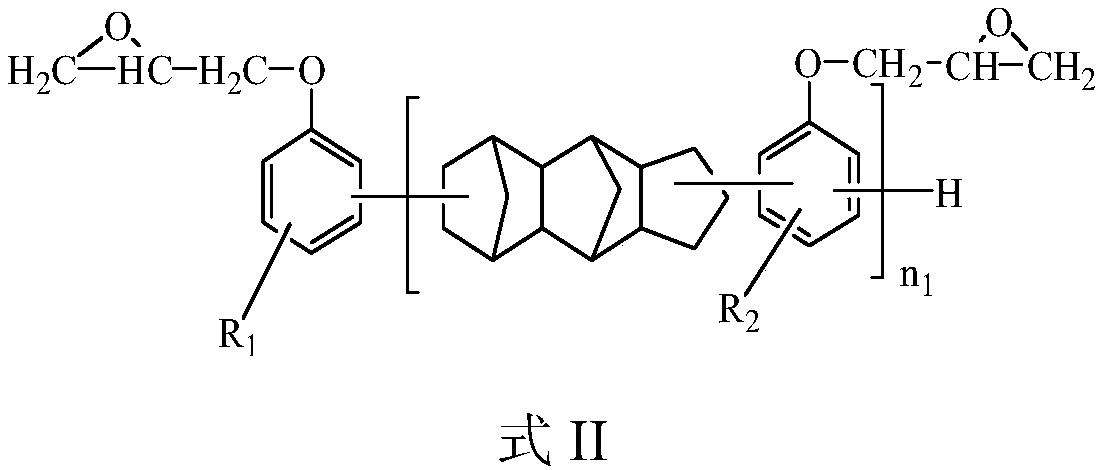

[0103] Preparation example 2: the epoxy resin synthesis of formula II structure

[0104] Add 136.8g of bisphenol A into a four-neck flask (500mL) equipped with a stirrer, a thermometer, and a condensing reflux device, and toluene as a solvent, dissolve in a water bath heating, weigh 1.4g of boron trifluoride etherate complex, add In the four-neck flask, add 39.6g TCPD into the dropping funnel, control the dropping speed so that all the TCPD is added dropwise within 2 hours, raise the temperature to 100-120°C, keep it warm for 5 hours, after the reaction is over, wash with water, filter, and recrystallize , and dried in vacuum to obtain a phenolic resin containing TCPD structure.

[0105] Put the 25g phenolic resin containing the TCPD structure obtained in the previous step into a four-necked flask, then weigh 100g epichlorohydrin and add slowly, after it dissolves, start to heat up, and add 1mol of mass fraction in the dropping funnel to be 33% NaOH solution, control the spee...

preparation example 3

[0107] Preparation example 3: the epoxy resin synthesis of formula I structure

[0108] Add 108g of o-cresol and toluene as a solvent in a four-neck flask (500mL) equipped with a stirrer, a thermometer, and a condensing reflux device, dissolve in a water bath heating, weigh 1.4g of boron trifluoride diethyl ether complex, add four In the flask, add 39.6g TCPD to the dropping funnel, control the dropping speed so that all the TCPD is added dropwise within 2 hours, raise the temperature to 100-120°C, keep it warm for 5 hours, after the reaction is over, wash with water, filter, and recrystallize. Vacuum drying to obtain the phenolic resin containing TCPD structure.

[0109]Put the 25g phenolic resin containing the TCPD structure obtained in the previous step into a four-necked flask, then weigh 100g epichlorohydrin and add slowly, after it dissolves, start to heat up, and add 1mol of mass fraction in the dropping funnel to be 33% NaOH solution, control the speed so that it can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com