Polymer modified graphene/polyvinylidene fluoride high-dielectric composite material and preparation method thereof

A technology of polyvinylidene fluoride and composite materials, applied in the field of composite materials, can solve problems such as difficult to meet and high dielectric loss factor, and achieve the effect of low dielectric loss factor and increased dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

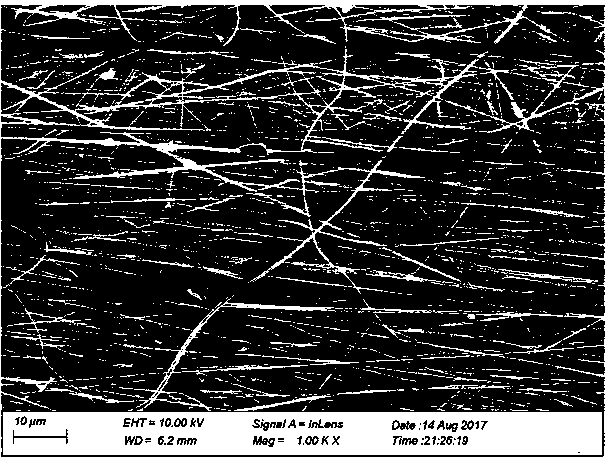

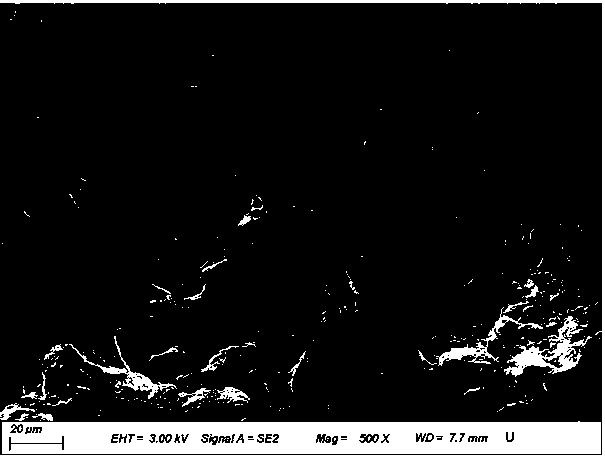

Image

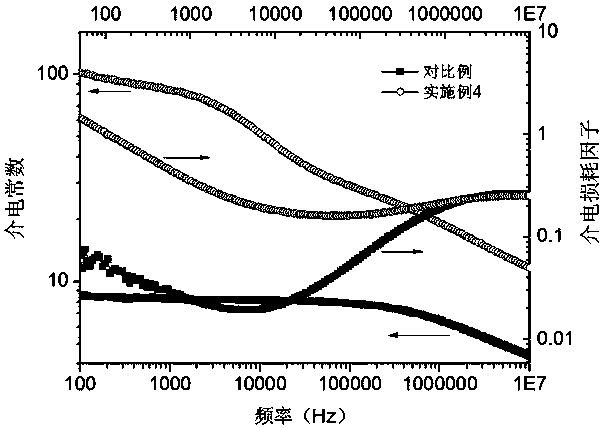

Examples

Embodiment 1

[0024] In this implementation, polyvinylidene fluoride-modified graphene was used as a dielectric functional filler to prepare a graphene / polyvinylidene fluoride composite material with a modified graphene content of 4 wt.%.

[0025] 1) Preparation of aminated graphene oxide

[0026] Disperse 2 grams of graphene oxide in a mixed solvent of 190 milliliters of absolute ethanol and 10 milliliters of water, and then add 0.2 grams of aminosilane KH550. After 30 minutes of ultrasonic mixing, the resulting solution is stirred and reacted at 60 degrees Celsius for 24 hours, and finally the reaction The obtained aminated graphene oxide was filtered, washed 6 times with distilled water, and dried under vacuum at 60° C. for 24 hours.

[0027] 2) Preparation of amino graphene

[0028] Disperse 2 grams of graphene oxide in 200 milliliters of distilled water and ultrasonically disperse it fully for 30 minutes, then slowly add 10 grams of sodium borohydride into the solution, and then heat ...

Embodiment 2

[0036] The preparation method and test method are the same as in Example 1, except that the graphene / polyvinylidene fluoride composite material with a polyvinylidene fluoride modified graphene content of 8wt.% is prepared, and the dielectric properties of the composite material at 1000 Hz are measured. The constant is 22.2 and the dielectric loss factor is 0.099.

Embodiment 3

[0038] The preparation method and test method are the same as in Example 1, except that the graphene / polyvinylidene fluoride composite material with a polyvinylidene fluoride modified graphene content of 12wt.% is prepared, and the dielectric properties of the composite material at 1000Hz are measured. The constant is 44.4 and the dielectric loss factor is 0.256.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com