Halogen-free and phosphorus-free epoxy resin composition and prepreg and laminated board produced therefrom

A technology of halogen-free phosphorus epoxy resin and phosphorus epoxy resin, which is applied in the field of electronic materials, can solve the problems of reducing the water absorption of the composition or the tolerance of the plate, the problem of dispersion is difficult to improve, and the hazard of waste to the aquatic environment. Good drilling processability, improved manufacturing processability, and reduced curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

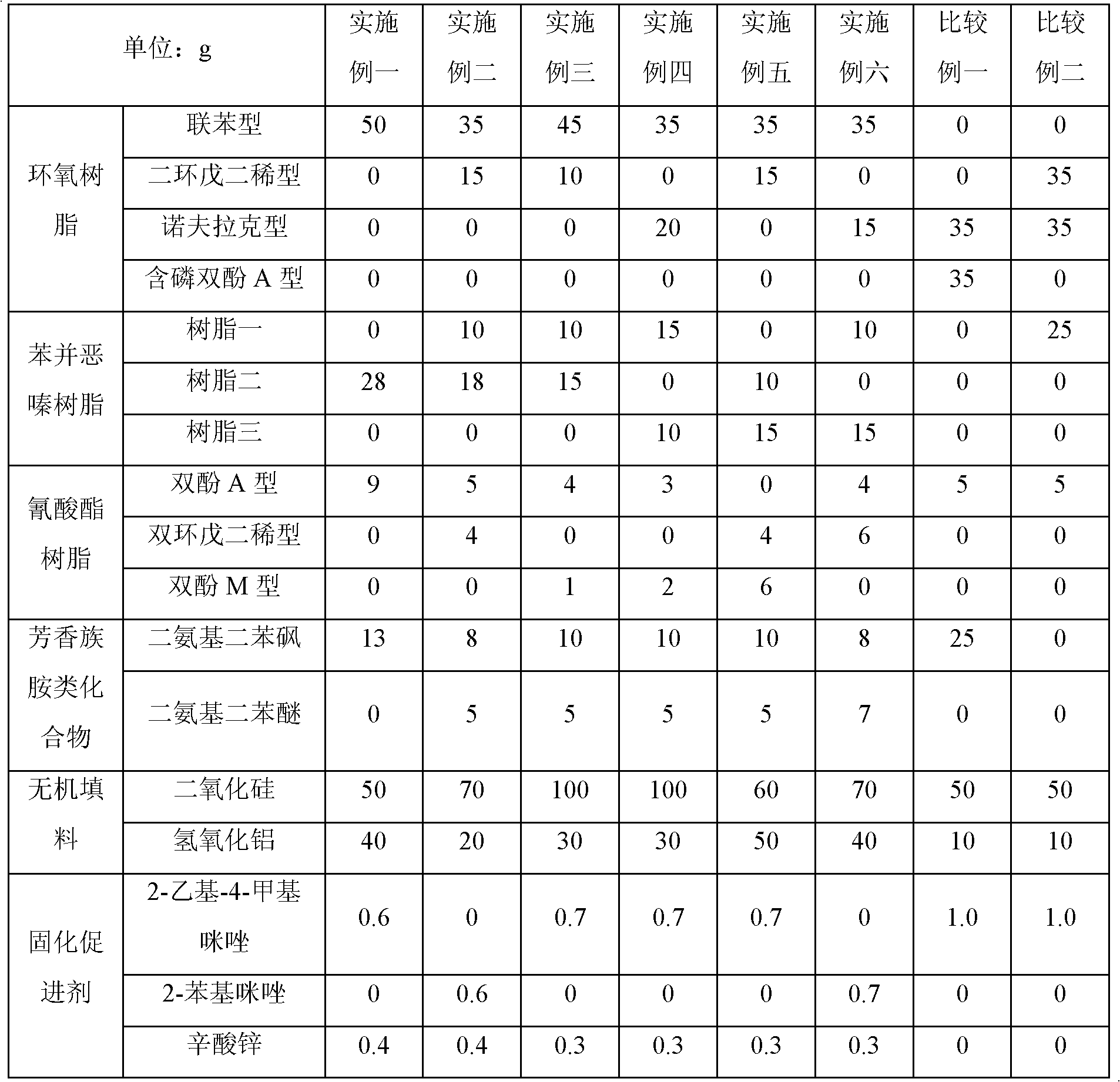

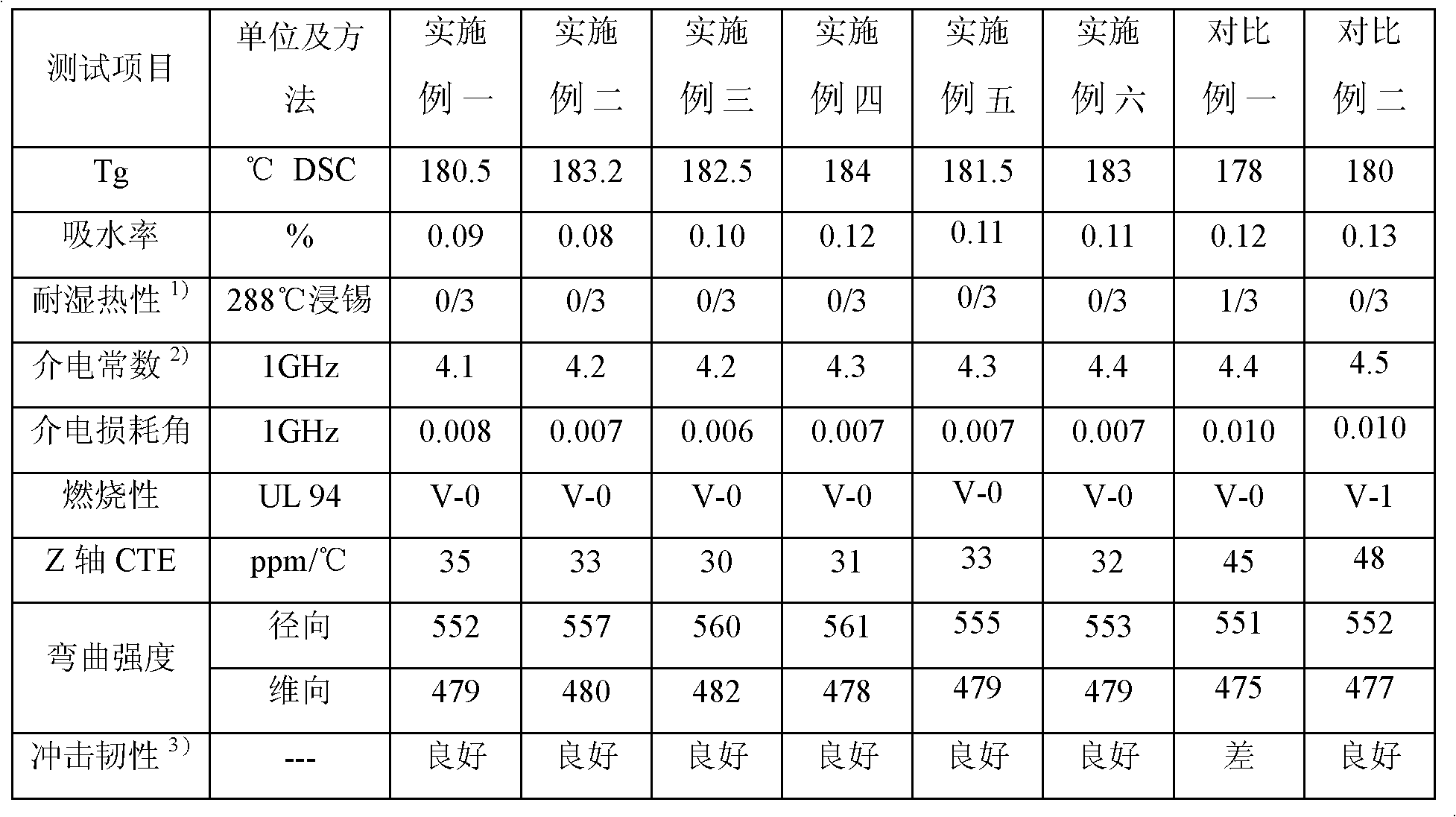

[0057] A kind of halogen-free phosphorus-free epoxy resin composition, adopts the component and proportioning in following table 1:

[0058] Table 1

[0059]

[0060] In the above table, resin one in the benzoxazine resin is polymerized from the following intermediates: Wherein, R1, R2, R3 are respectively selected from -H, -H, -NH 2 ; R4 is selected from -C 6 h 5 ;

[0061] Resin II is polymerized from the following intermediates: Among them, R is selected from n=2;R 1 , R 2 Both are -H;

[0062] Resin 3 is polymerized from the following intermediates: Among them, R 1 , R 2 Both are -H; R is n=2.

[0063] In embodiment one to six,

[0064] The glue mixing method is as follows:

[0065] Weigh 45-60 parts of epoxy resin, 5-10 parts of cyanate resin, 20-35 parts of benzoxazine resin, 12-25 parts of diaminodiphenyl sulfone, add to acetone, stir to make it completely mixed , to obtain 100 parts of halogen-free and phosphorus-free epoxy resin compositions; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com