Thermosetting resin composition and prepreg and laminate prepared therefrom

A resin composition and thermosetting technology, applied in the field of laminates, can solve the problems of difficult to meet the requirements of green environmental protection, high curing temperature of bismaleimide, environmental pollution, etc., to improve heat resistance and dielectric properties , Reduce the dielectric constant, improve the effect of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

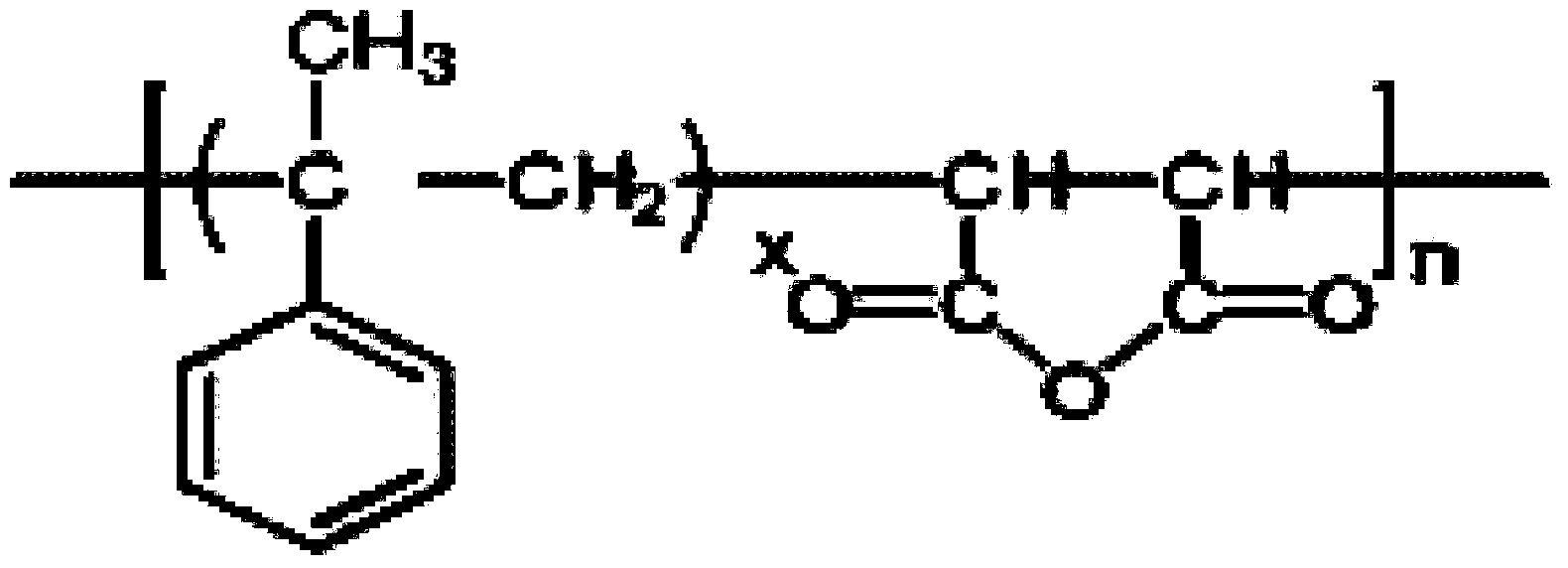

[0046] Preparation example, the synthesis of phenylpropylene-maleic anhydride

[0047] Under the condition of nitrogen protection and stirring, add monomer maleic anhydride and initiator into the medium to dissolve, and when heated to 60-80°C, add monomer styrene and molecular weight regulator dropwise, continue stirring after dropwise addition React for 1-8h to obtain a dispersion system of low molecular weight styrene / maleic anhydride polymer particles, centrifuge and dry the dispersion to obtain a low molecular weight styrene / maleic anhydride alternating copolymer; wherein the initiator is Organic peroxides or azo compounds; the medium is a mixed solution of organic acid alkyl esters and alkanes; the molecular weight regulator is vinyl acetate; the amount of maleic anhydride and propylene is 1: 0.90-0.96; the sum of the mass concentrations of the two monomers maleic anhydride and phenylpropylene in the reaction system is 2.0-7.5%; the mass concentration of the initiator in ...

Embodiment

[0051] Embodiment, the preparation method of copper clad laminate

[0052] Put cyanate ester, epoxy resin, styrene-maleic anhydride, polyphenylene ether, halogen-free flame retardant, curing accelerator, filler and solvent into a container, stir to mix evenly, and make glue. Use a solvent to adjust the solid content of the solution to 60%-70% to make a glue solution, that is, to obtain a thermosetting resin composition glue solution, impregnate the glue with 2116 electronic grade glass fiber cloth, bake in an oven to form a prepreg, and take 6 2116 prepregs, Cover both sides with 35μm thick electrolytic copper foil, vacuum laminate in a hot press, and cure at 190°C / 120min to make a copper clad laminate.

[0053] Each component used in Examples 1-6 and Comparative Examples 1-5 and its content (by weight) are as shown in Table 1, and each component code and its corresponding component name are as follows:

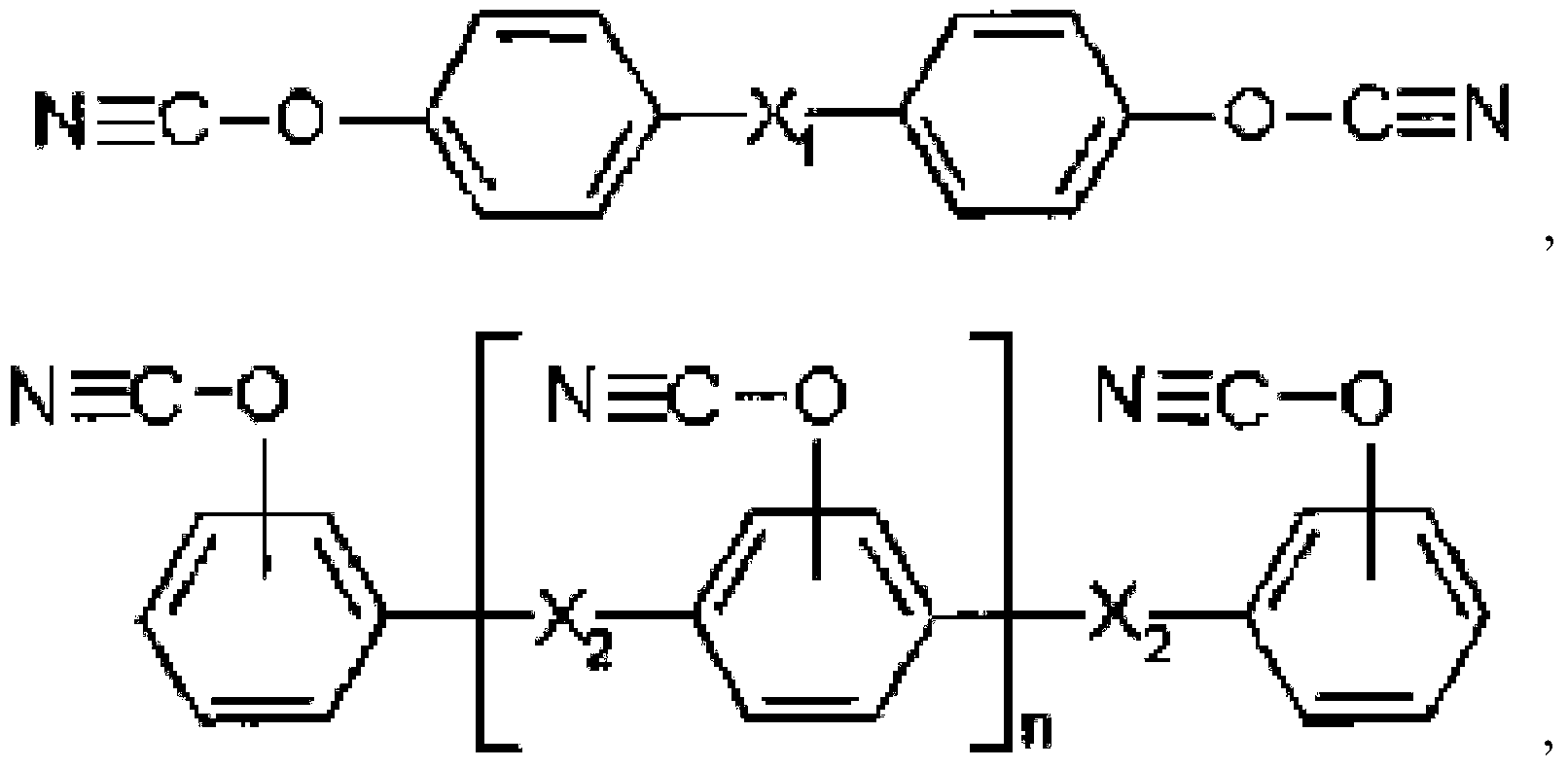

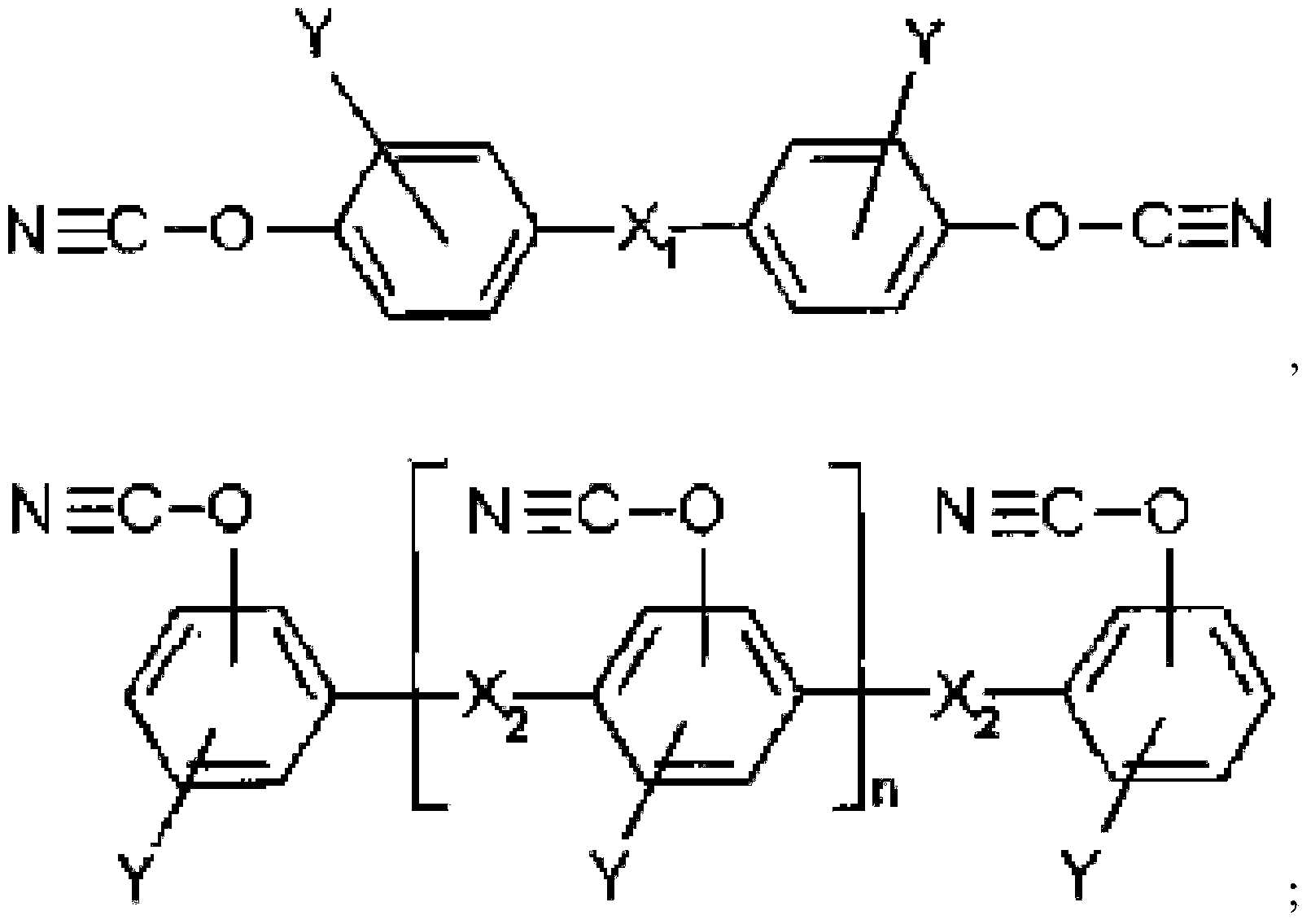

[0054] (A) Cyanate: HF-10 (Shanghai Huifeng Science and Trade Trade Nam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com