Modified cyanate coating

A cyanate ester and modification technology, applied in the coating and other directions, can solve the problems such as the inability of graphene to disperse and the inability of materials to achieve the modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

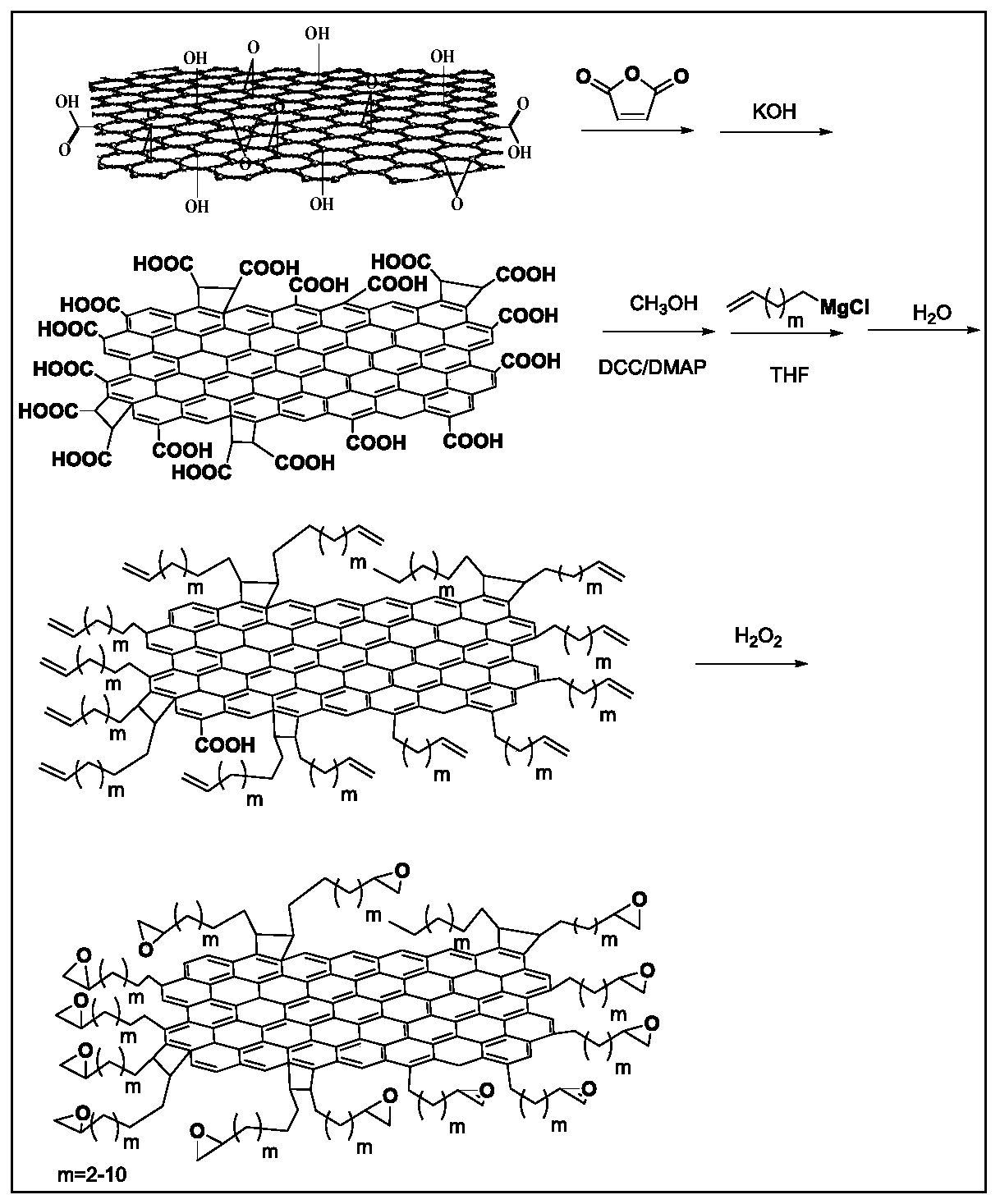

[0068] First, the graphite or graphene material is oxidized by the Hummers method to obtain graphene oxide. 0.2 g of graphene oxide was ultrasonically dispersed in 100 ml of tetrahydrofuran solution for 10 minutes, and a graphene oxide colloidal solution was obtained after ultrasonic dispersion.

[0069] Then add 0.4 g of maleic anhydride to the graphene oxide colloidal solution, and ultrasonically disperse for 10 minutes. The graphene oxide / maleic anhydride / THF mixture was irradiated in a Co-60 source with a radiation dose of 30 kGy and a dose rate of 15 Gy / min. The modified graphene oxide is obtained after the insoluble matter in the mixed solution after irradiation is suction-filtered, washed to neutrality and dried.

[0070] Weigh 0.2 g of modified graphene oxide, soak in 1 mmol / L KOH aqueous solution and 1 mmol / L hydrochloric acid solution for 5 minutes and 10 minutes respectively for hydrolysis. After the product was suction-filtered and washed with deionized water to ...

Embodiment 2

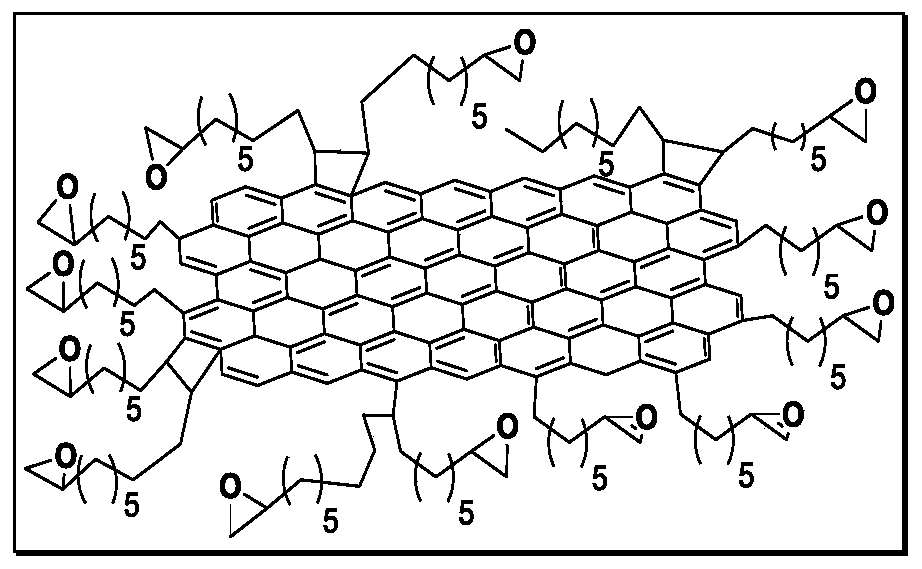

[0076] Take 1g of graphene modified by epoxy group, its structure is as follows figure 2 Shown, through titration and theoretical calculation (graphene surface density is 0.77mg / m 2 meter), the areal density of epoxy groups on its surface is 12.4nmol / cm 2 . The graphene modified by this epoxy group is added in the tetrahydrofuran of 100ml, stir; Get 100g tetramethyl bisphenol F type cyanate and graphene tetrahydrofuran solution and stir again, obtain modified cyanate coating, wait After the solution is completely volatilized, it solidifies and forms. The properties of the cured product are shown in Table 1.

[0077] figure 2 Chemical structure of epoxy-functionalized graphene in Example 1.

Embodiment 3

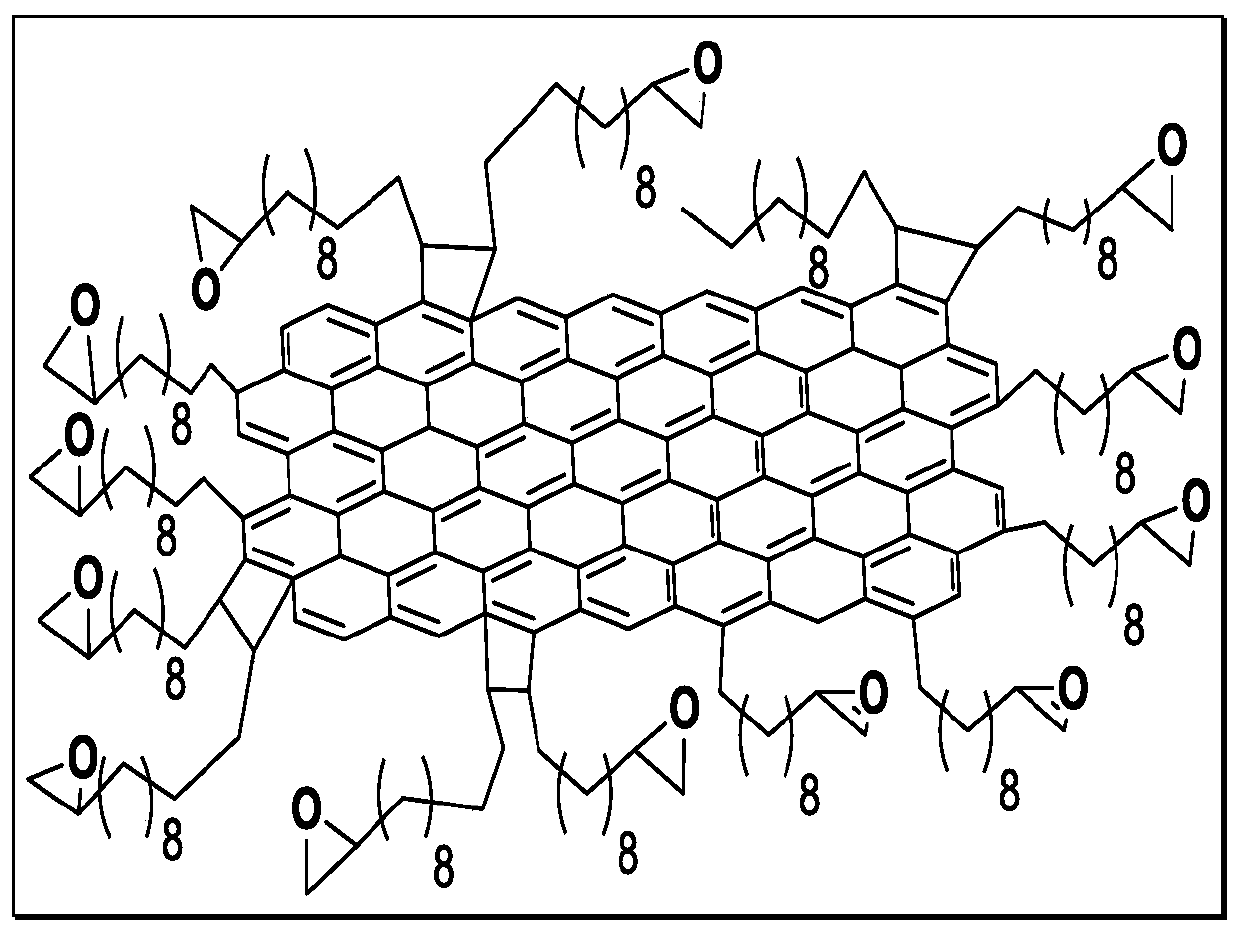

[0079] Take 1g of graphene modified by epoxy group, its structure is as follows image 3 Shown, through titration and theoretical calculation (graphene surface density is 0.77mg / m 2 meter), the areal density of epoxy groups on its surface is 18.5nmol / cm 2 . Add the epoxy group-modified graphene into 80ml of tetrahydrofuran, and stir evenly. Then take 80g of tetramethylbisphenol F-type cyanate and graphene solution and stir evenly to obtain a modified cyanate coating, and after the solution is completely volatilized, solidify and form. The properties of the cured product are shown in Table 1.

[0080] image 3 Epoxy functionalized graphene chemical structure in embodiment 2

[0081] Table 1 Performance comparison table of cured products of modified cyanate ester coatings

[0082]

[0083]

[0084] Note: the structural formula of cyanate in Table 1 is as follows:

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com