Ceramic electronic component

An electronic component and ceramic technology, applied in the field of ceramic electronic components, can solve the problems of difficulty in achieving high capacity and large capacity, difficulty in meeting product size specifications, and large-scale product size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

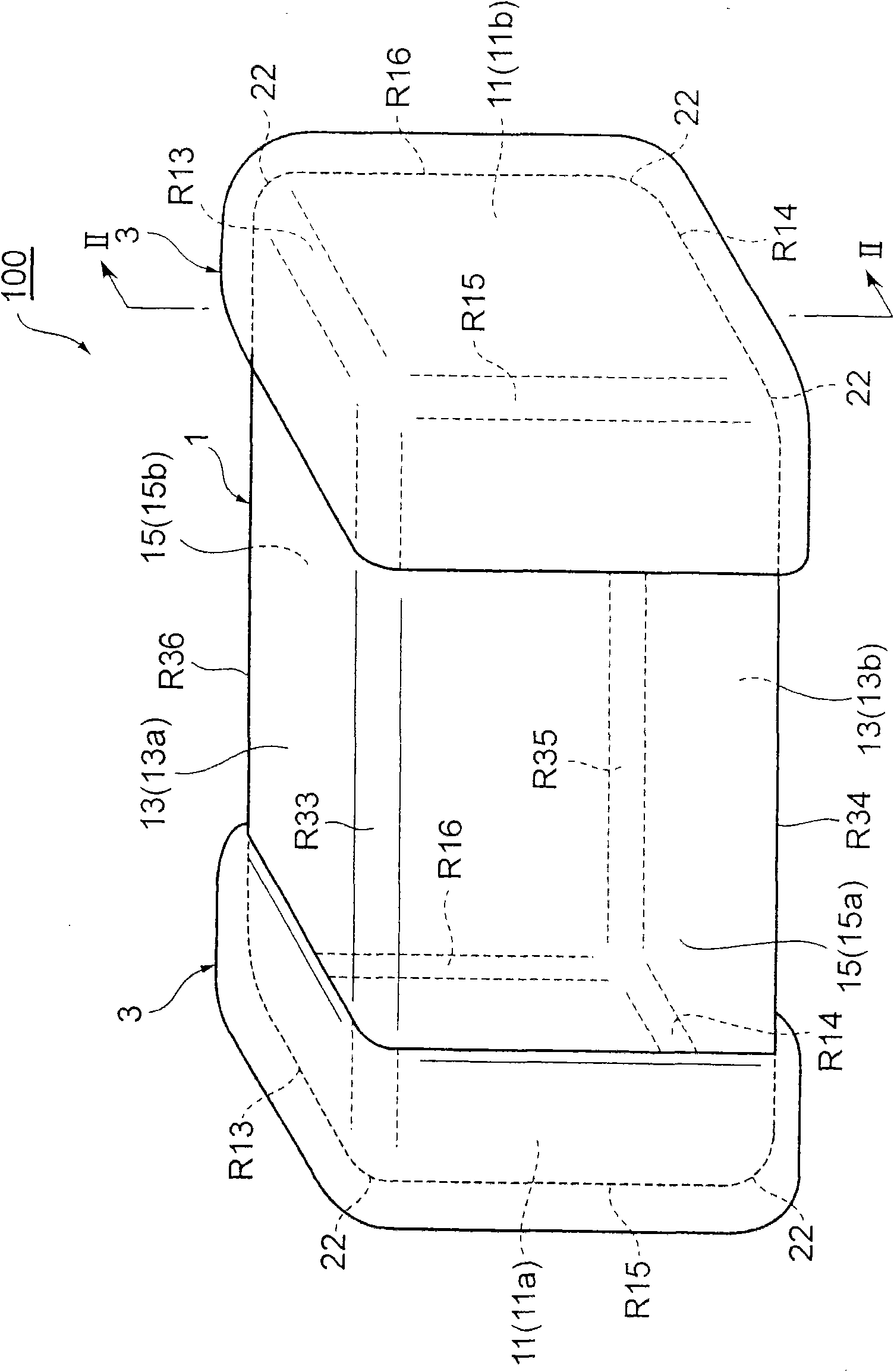

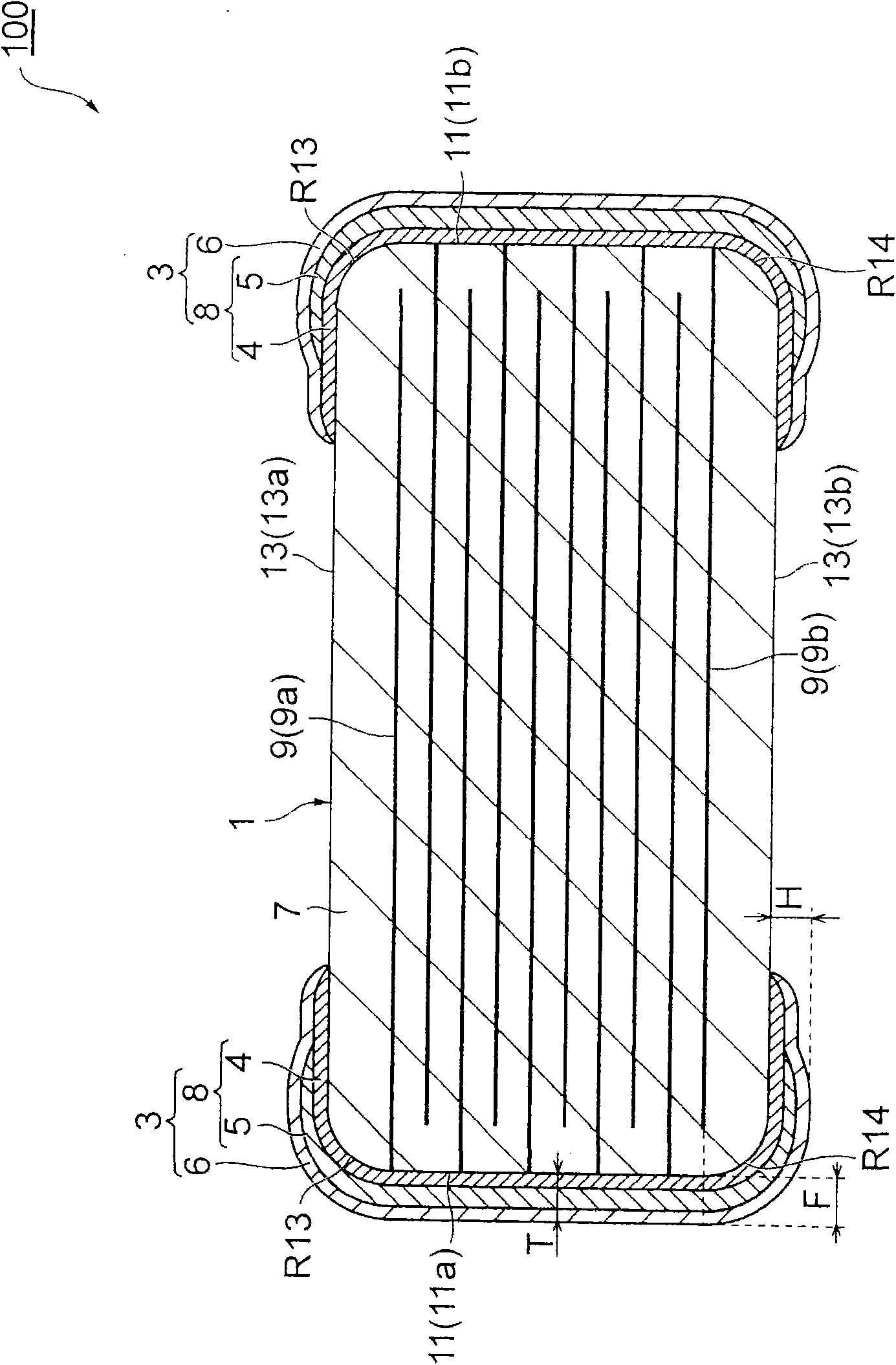

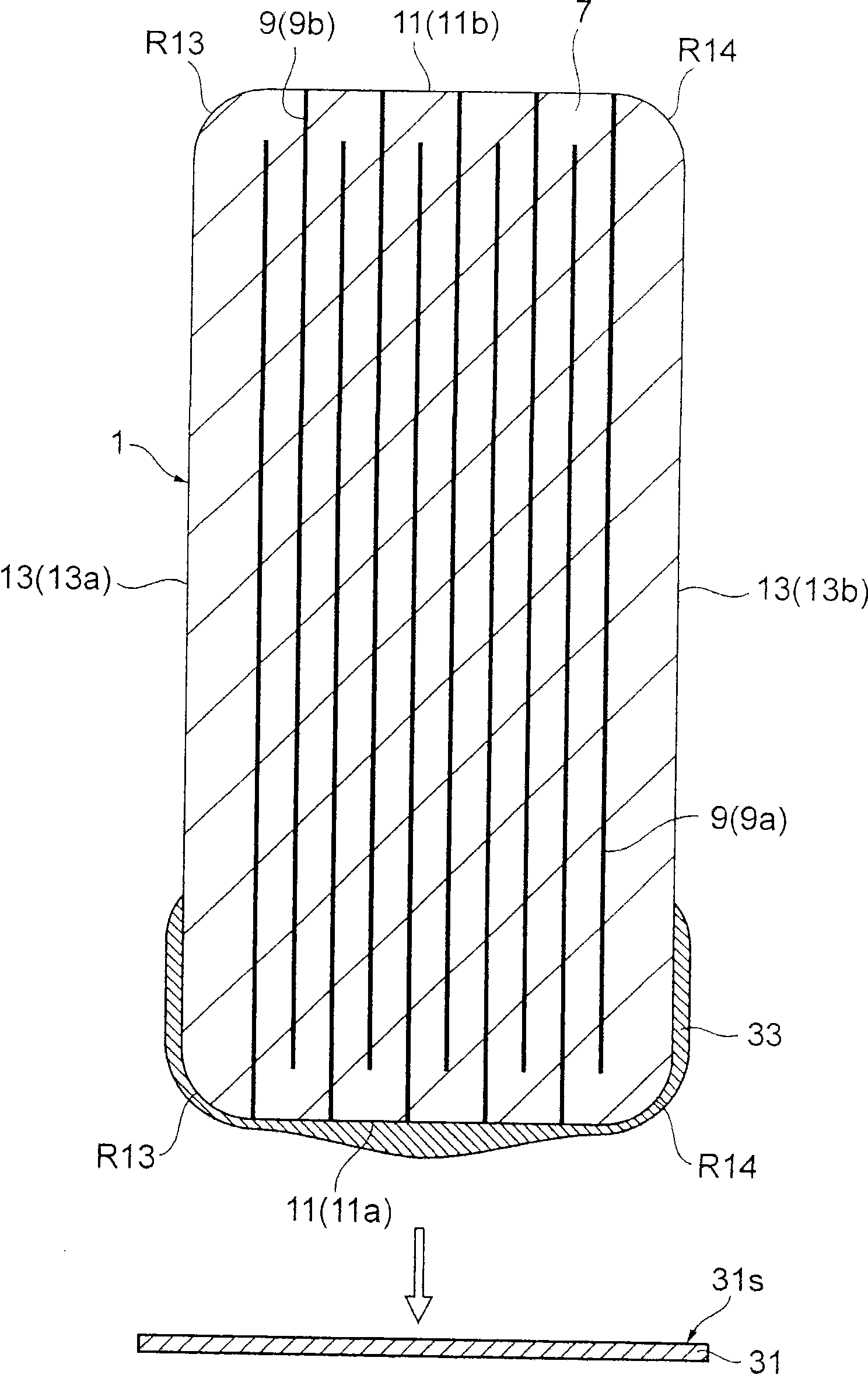

Embodiment 1

[0066]

[0067] Mix commercially available BaTiO 3 Powder, binder, organic solvent and plasticizer to prepare ceramic slurry. After coating this ceramic slurry on a PET film using a doctor blade method or the like, it is dried to form a ceramic green sheet.

[0068] An electrode paste mixed with Cu powder or Ni powder with a binder, a solvent, etc. is screen-printed on the formed ceramic green sheet, and dried to form a green sheet with an electrode pattern.

[0069] By repeating the same method, a plurality of green sheets with electrode patterns were formed and laminated to produce a laminated body. Next, the laminated body of the electrode patterned green sheets is cut perpendicular to the lamination direction to form a cuboid-shaped laminated chip, heat-treated, and debonded. The heat treatment is performed at 180 to 400° C. for 0.5 hours or more. The stacked chips obtained by heat treatment are fired at 800-1400°C for 0.5-8.0 hours, and then barrel-polished to chamfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com