Three-station vacuum arc extinguish chamber for isolated grounding

A vacuum interrupter, isolation and grounding technology, applied in the direction of high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the disadvantages of vacuum interrupter, increase the complexity of materials, components and tests, and increase the size of switchgear components and other problems, to achieve the effect of simple structure, low cost, and improved insulation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

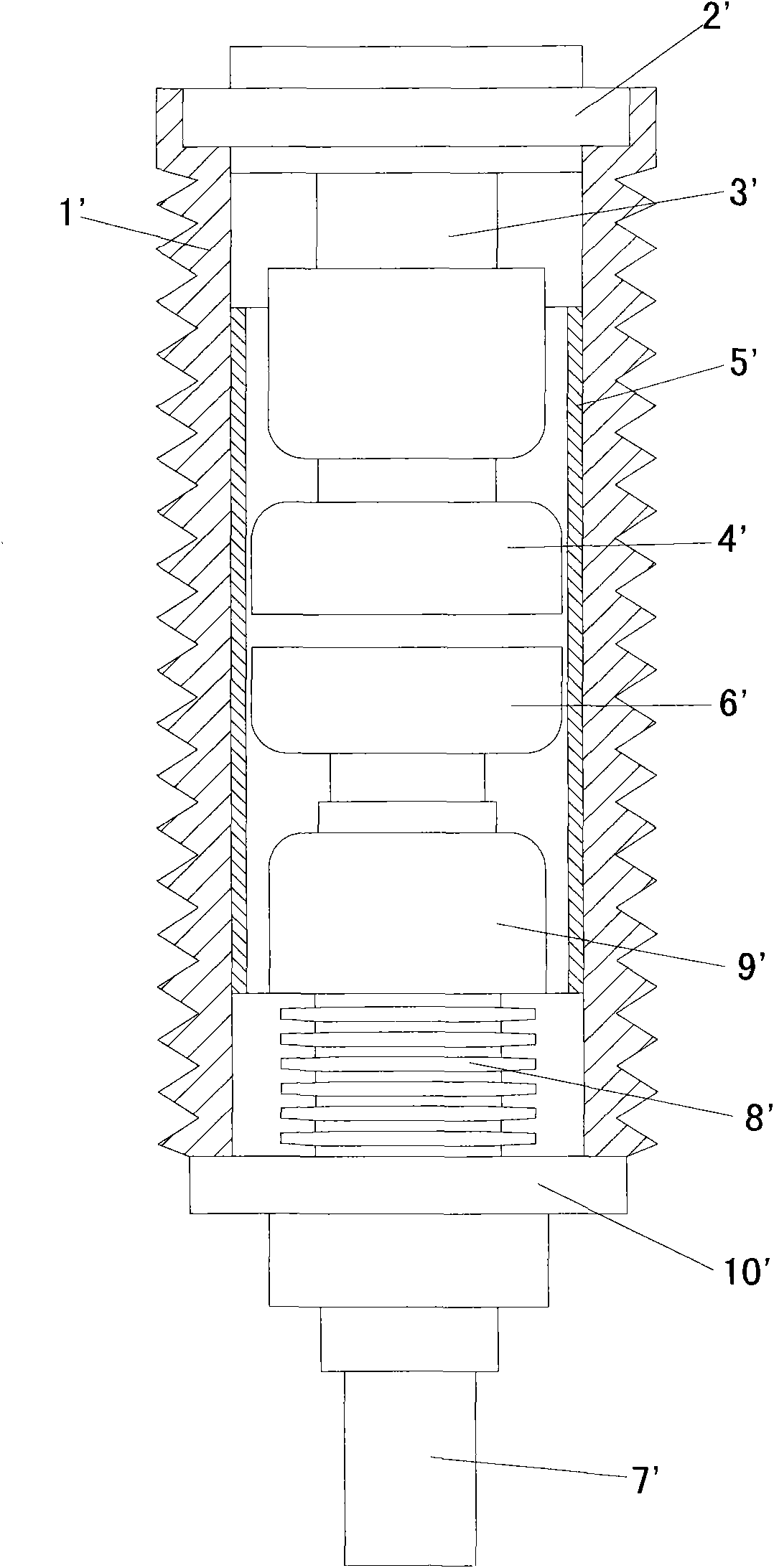

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

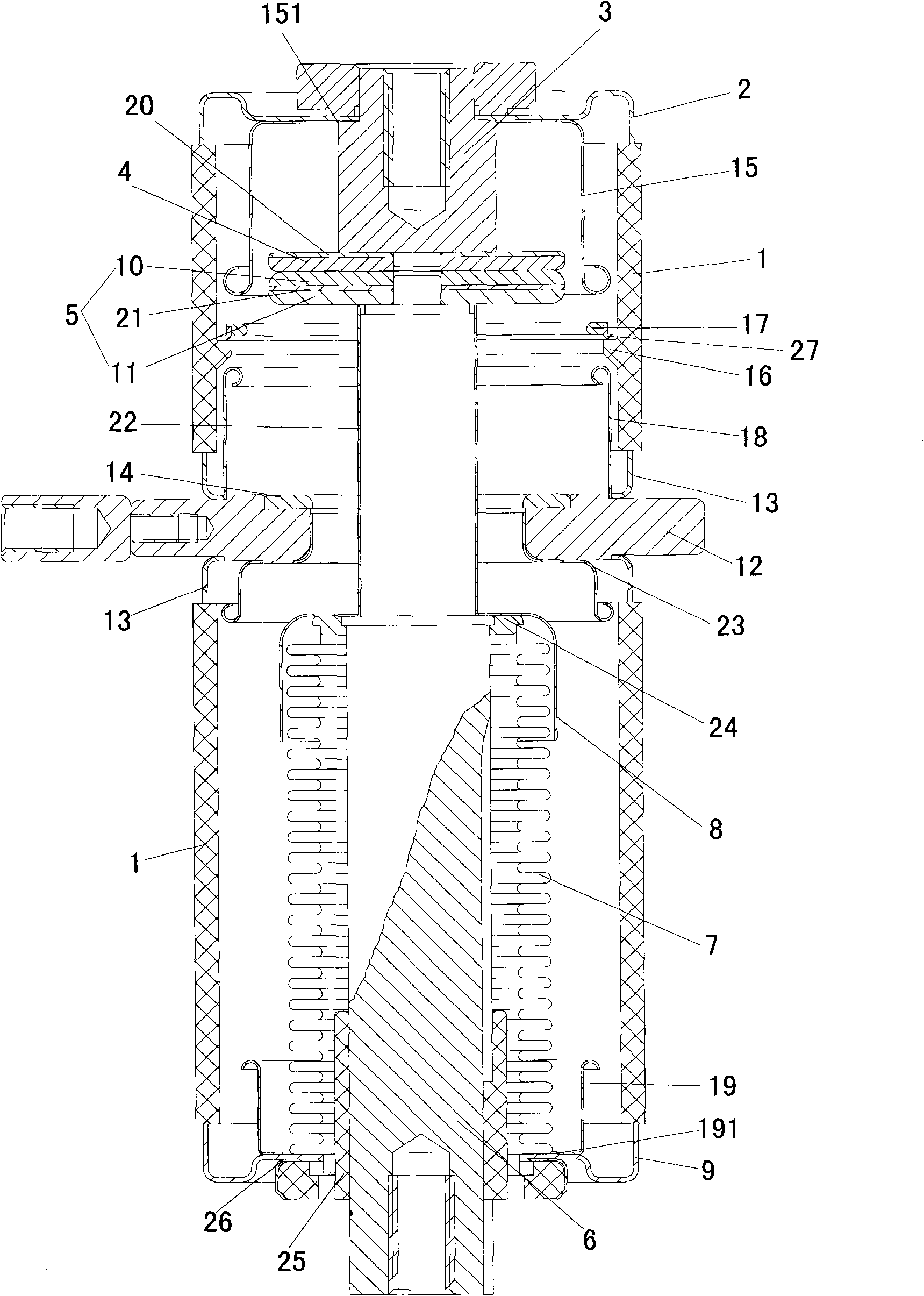

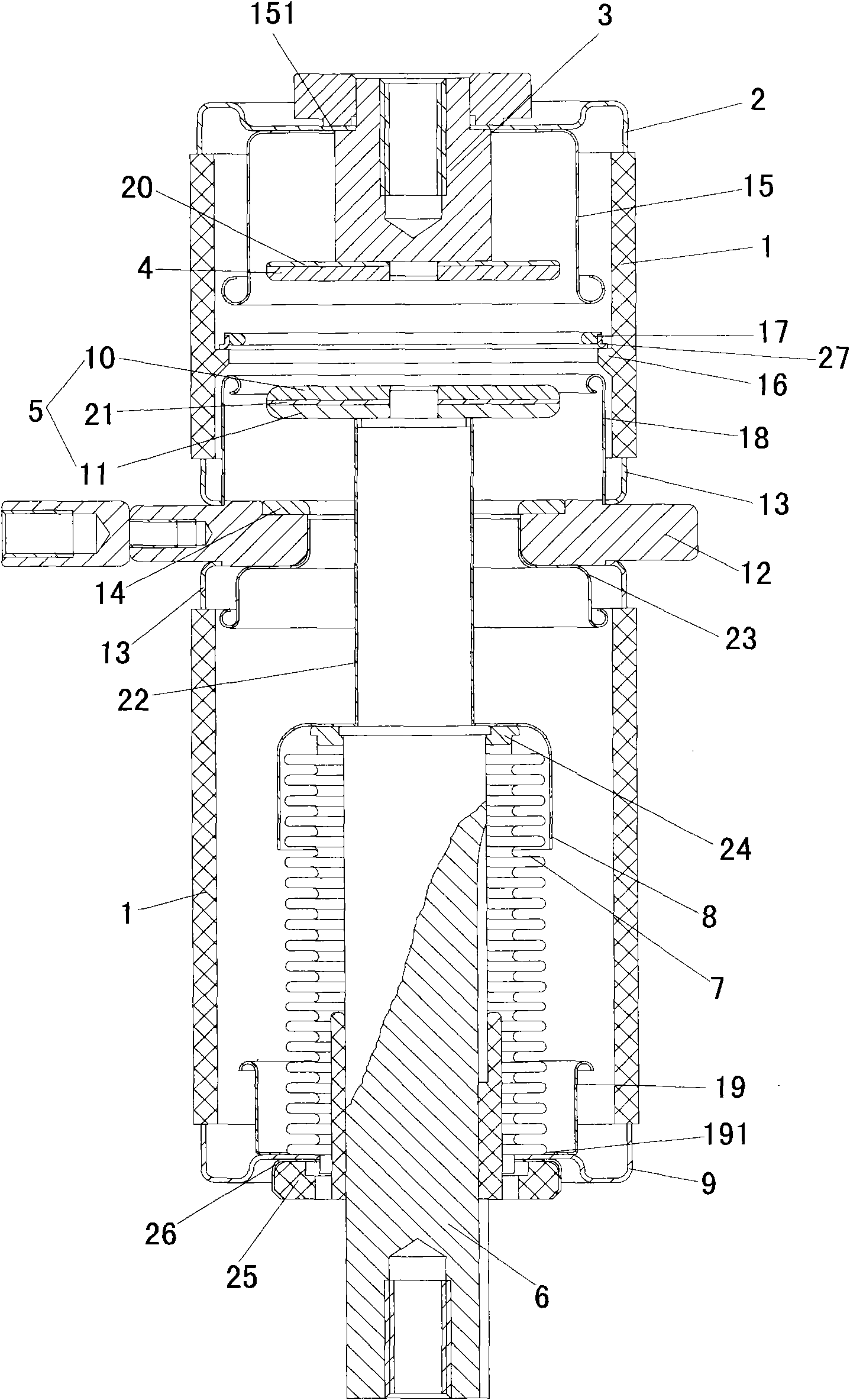

[0022] see figure 2 The schematic diagram of the structure of the closed state of the three-station vacuum interrupter for isolation and grounding of the present invention is shown, including an insulating shell 1, a static cover plate 2, a static end conductive rod 3, a static contact 4, a moving contact 5, and a moving end conductive rod. Rod 6, bellows 7, bellows protective cover 8, moving cover 9, static ground contact 14, static end isolation shield 15, intermediate isolation shield 17, ground isolation shield 18 and moving end equalizing cover 19. The moving contact 5 is welded by the moving isolating contact 10, the second copper sheet 21 and the moving grounding contact 11, the static contact 4 and the moving isolating contact 10 are made of copper-tungsten alloy, the static grounding contact 14 and the moving The ground contact 11 is made of copper chromium alloy.

[0023] The static cover plate 2 and the movable cover plate 9 are respectively arranged at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com