Silent range hood

A range hood, mute technology, applied in the field of range hoods, can solve problems such as loud noise, and achieve the effect of smooth airflow and accelerated airflow rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

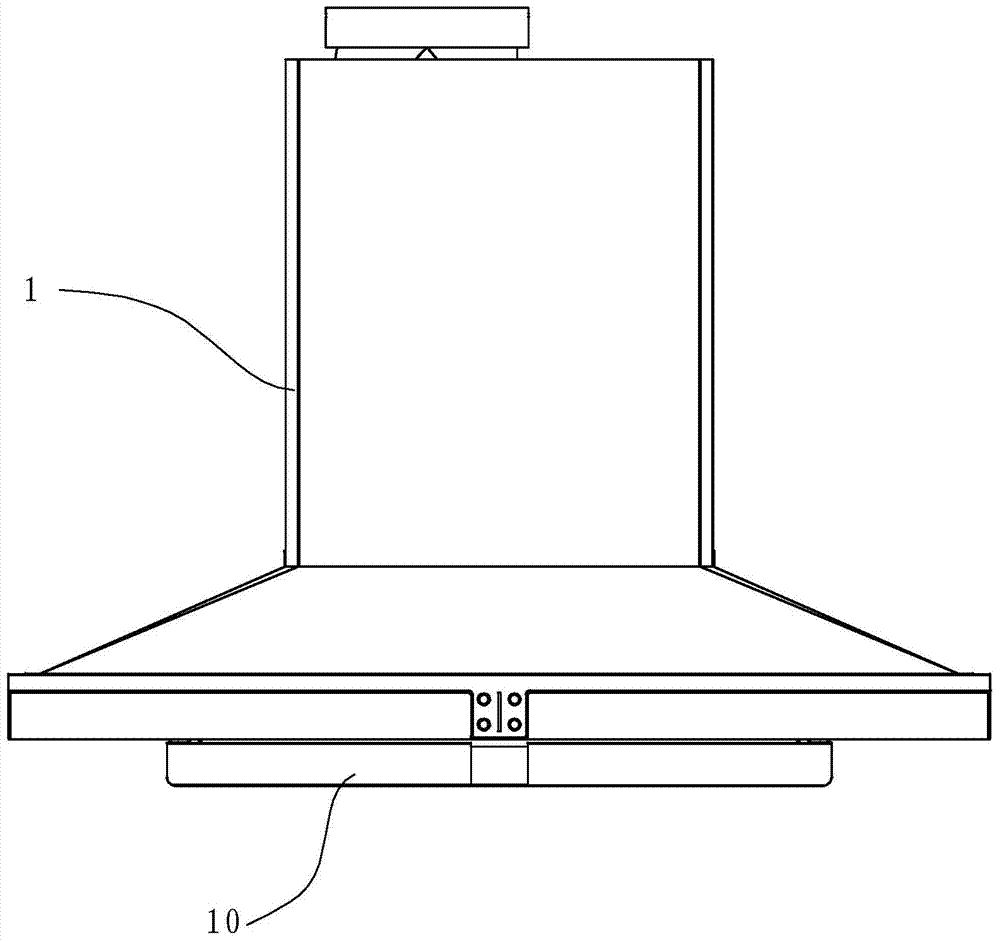

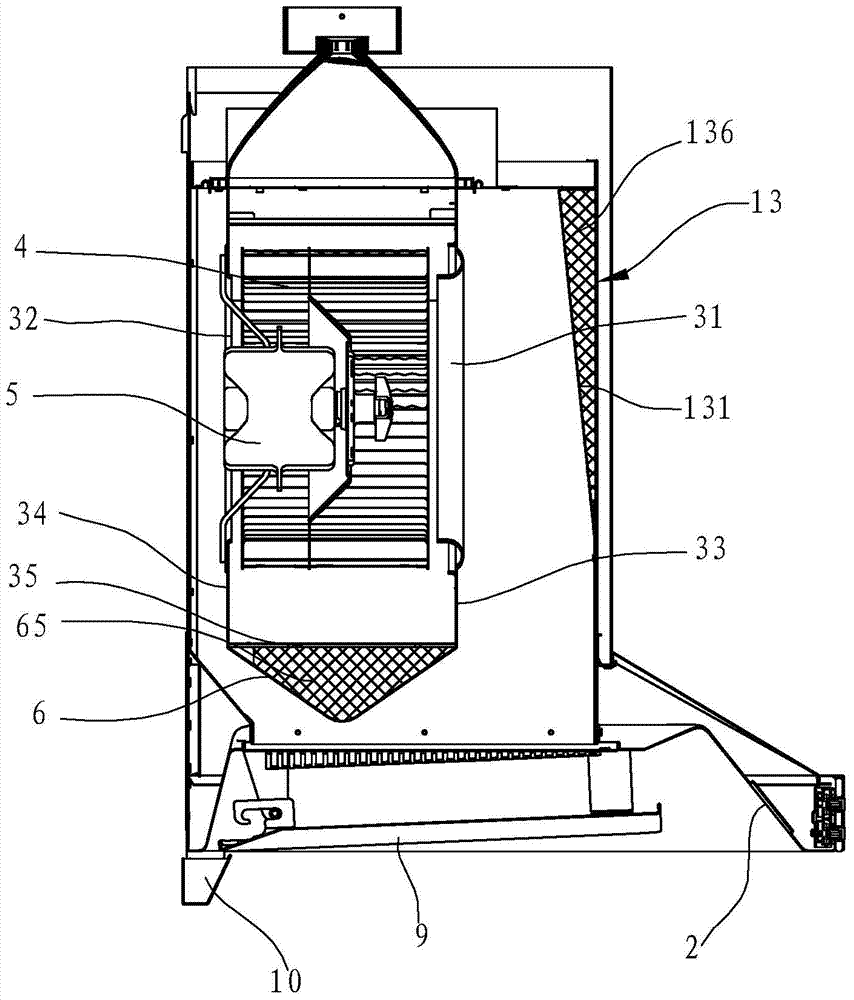

[0034] See Figure 1-Figure 3 , A silent type range hood, comprising a casing 1 and a fume collecting hood 2. The casing 1 includes a casing front cover 11 and a casing rear cover 12. The casing 1 is provided with a volute 3 and a volute 3 An impeller 4 and a motor 5 for driving the impeller 4 are provided inside.

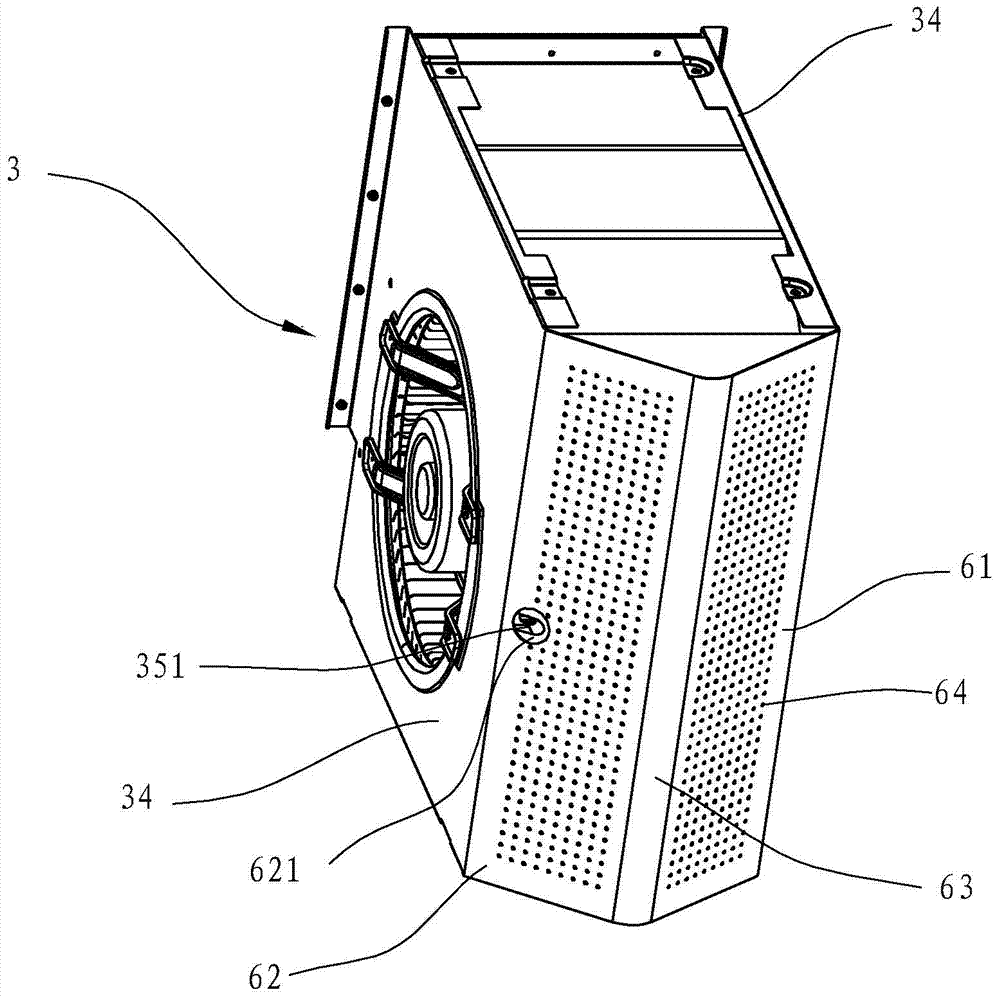

[0035] The volute 3 has a forward air inlet 31 and a rear air inlet 32. The housing front cover 11 of the housing 1 is opposite to the forward air inlet 31, and the sound-absorbing shroud 13 facing the forward air outlet 31 is fixed on the inner side of the front cover 11 of the housing. See Figure 4-Figure 5 , The sound-absorbing shroud 13 includes a rear panel 131 that is arranged obliquely opposite to the forward air outlet 31, and the distance between it and the front cover 11 of the casing is gradually reduced from top to bottom. Both sides of the rear panel 131 and the front cover of the casing There are end faces 132 between the plates 11, the width of the end...

Embodiment 2

[0044] See Figure 10-Figure 12 In this embodiment, the difference from the first embodiment is that the wind deflector 6 is only provided with second micro-holes 64 on the rear flat plate 62, and only the second sound-absorbing plate 62 is provided on the inner wall of the rear flat plate 62. The shape of the cotton 65 and the second sound-absorbing cotton 65 is consistent with the shape of the cavity formed from the inner wall of the rear flat panel 62 to the upper part of the arc panel 63.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com