Method for manufacturing a semiconductor pressure sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

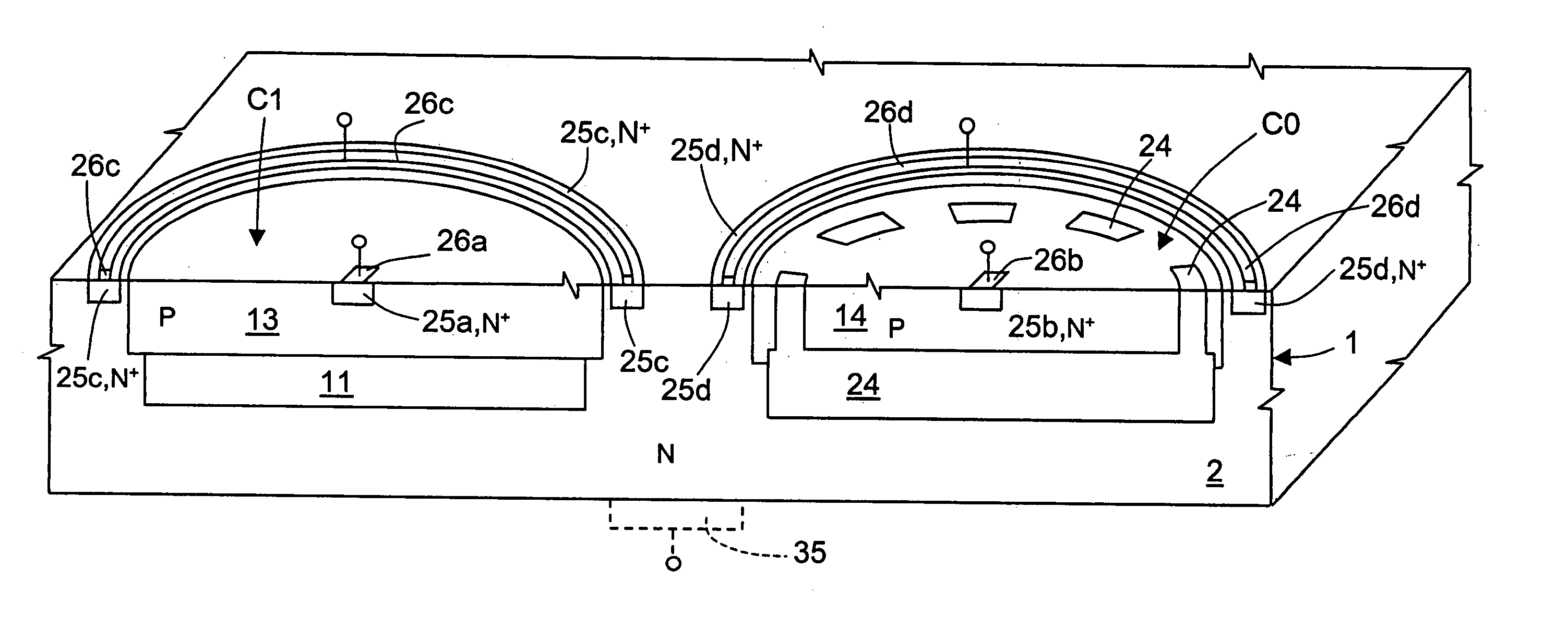

[0029] Hereinafter, an embodiment of a process for manufacturing a semiconductor material sensor of capacitive type is described. The present process is based upon the process disclosed in U.S. application Ser. No. 10 / 327,702 for manufacturing a SOI wafer, and, more precisely, refers to the second embodiment shown in FIGS. 11-14 of said document.

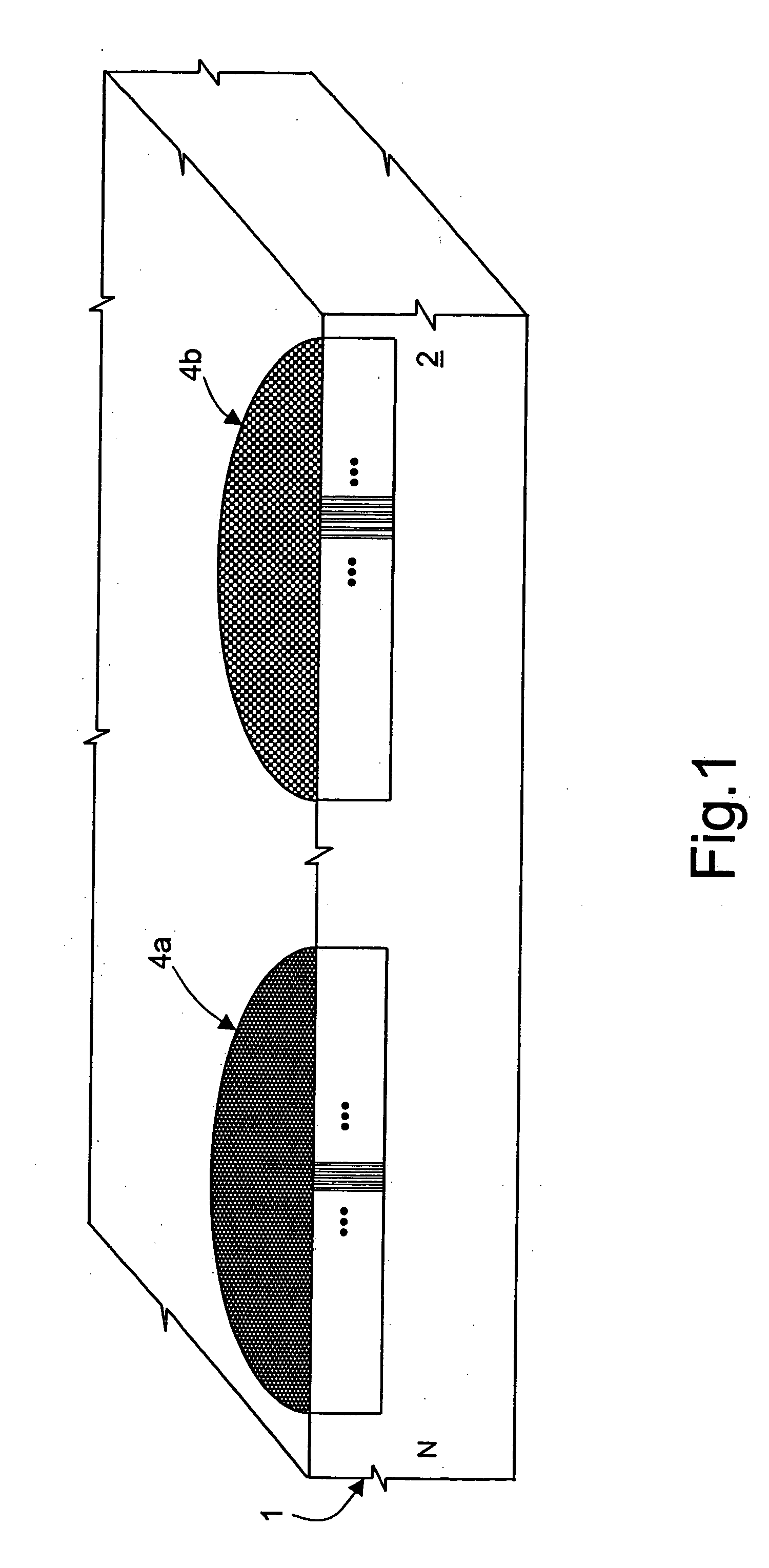

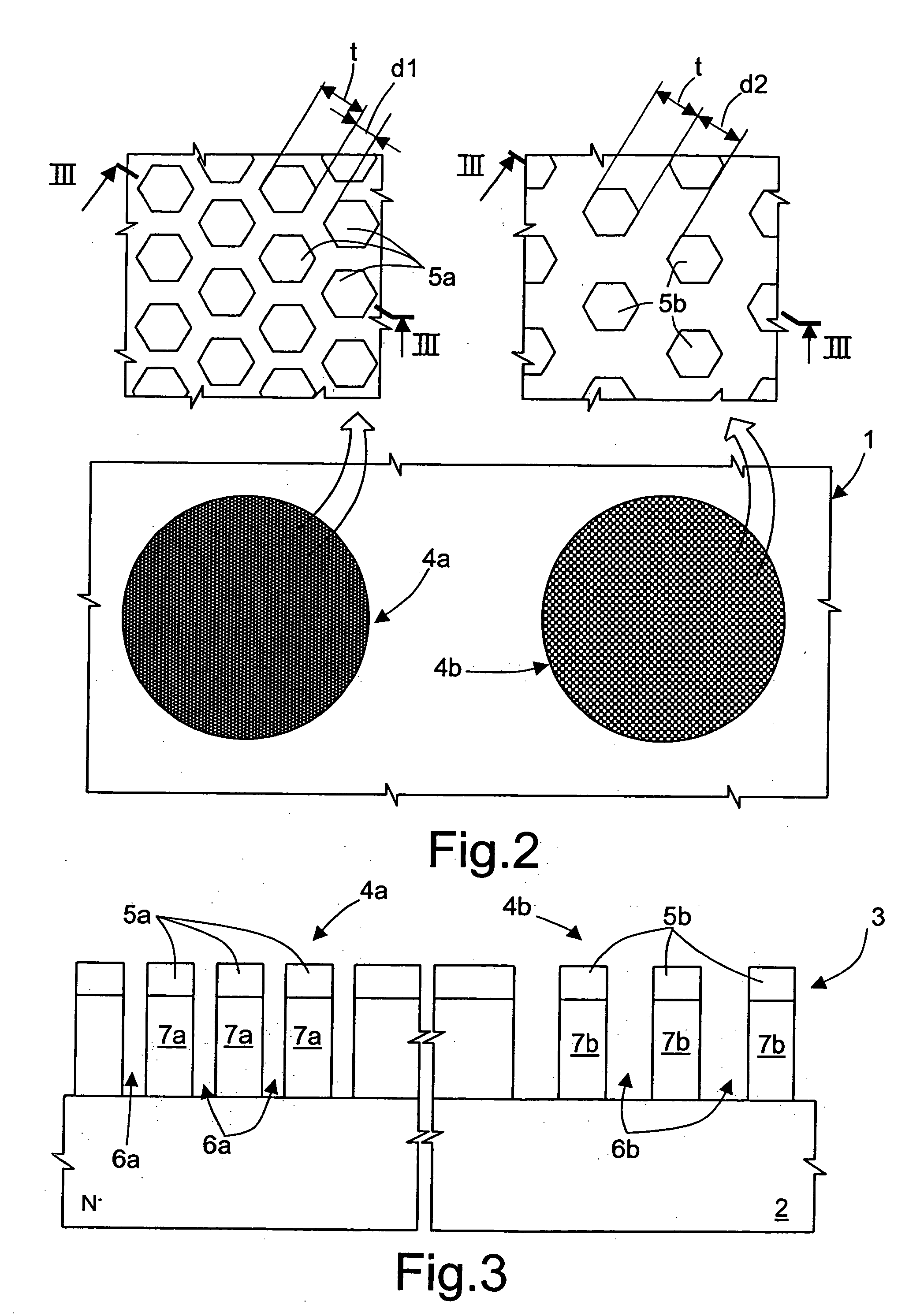

[0030]FIG. 1 shows a wafer 1 of semiconductor material, preferably monocrystalline silicon, comprising an N-type substrate 2, designed to form the bulk of the device. A resist mask 3 (visible in the enlarged detail of FIG. 3) is formed on the top surface of the substrate 2. The mask 3 has two circular areas, designated by 4a and 4b and hereinafter referred to as sensor area and reference area, respectively. In each of these areas, a honeycomb lattice is defined, the two lattices being of different sizes.

[0031] In particular, as appears in the enlarged detail of FIG. 2, the sensor area 4a has mask regions 5a with an hexagonal shape arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com