Integral fuel jet axial swirler pre-mixing preevaporated low pollution combustion-chamber

A technology of fuel injection and swirler, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of increasing the length and weight of the engine, increasing the axial length of the head of the combustion chamber, etc., and achieve the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

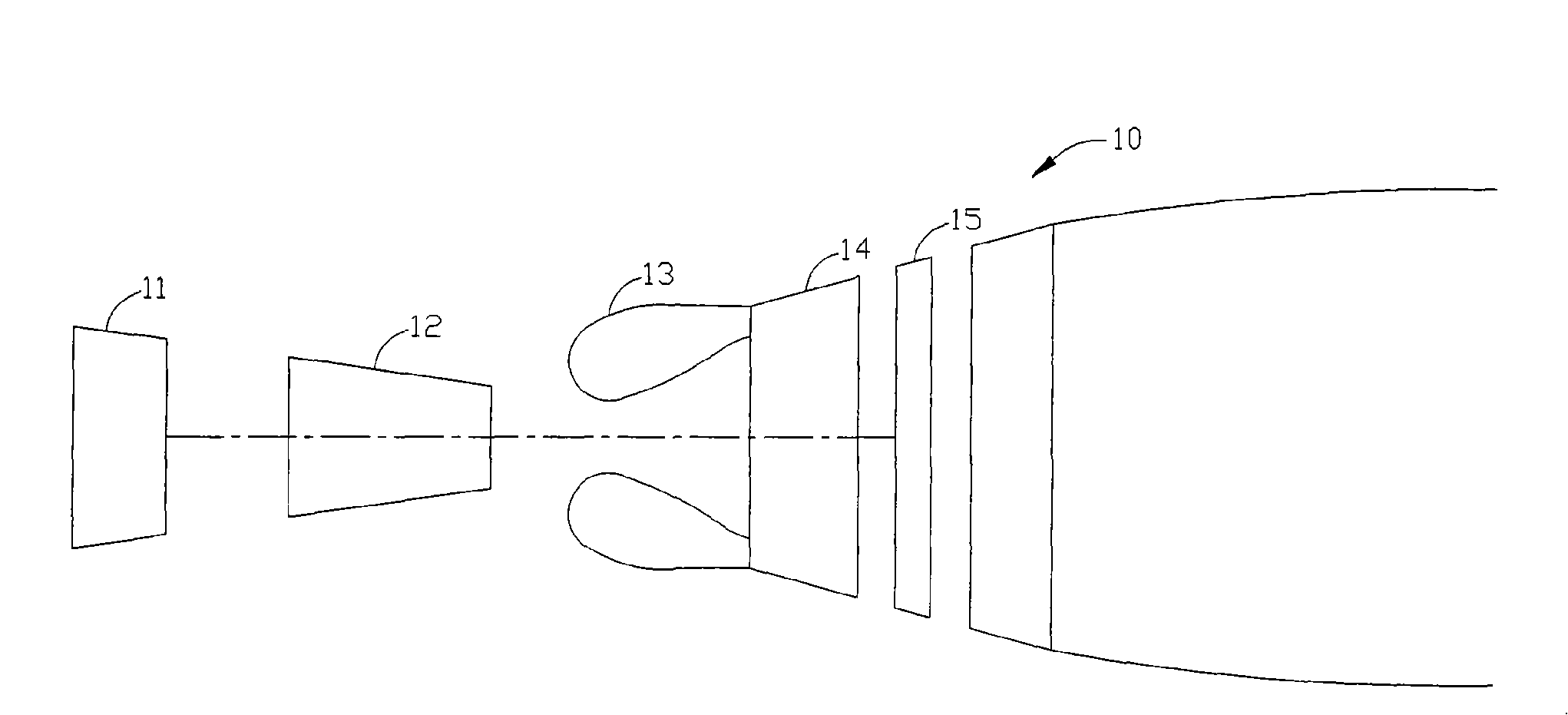

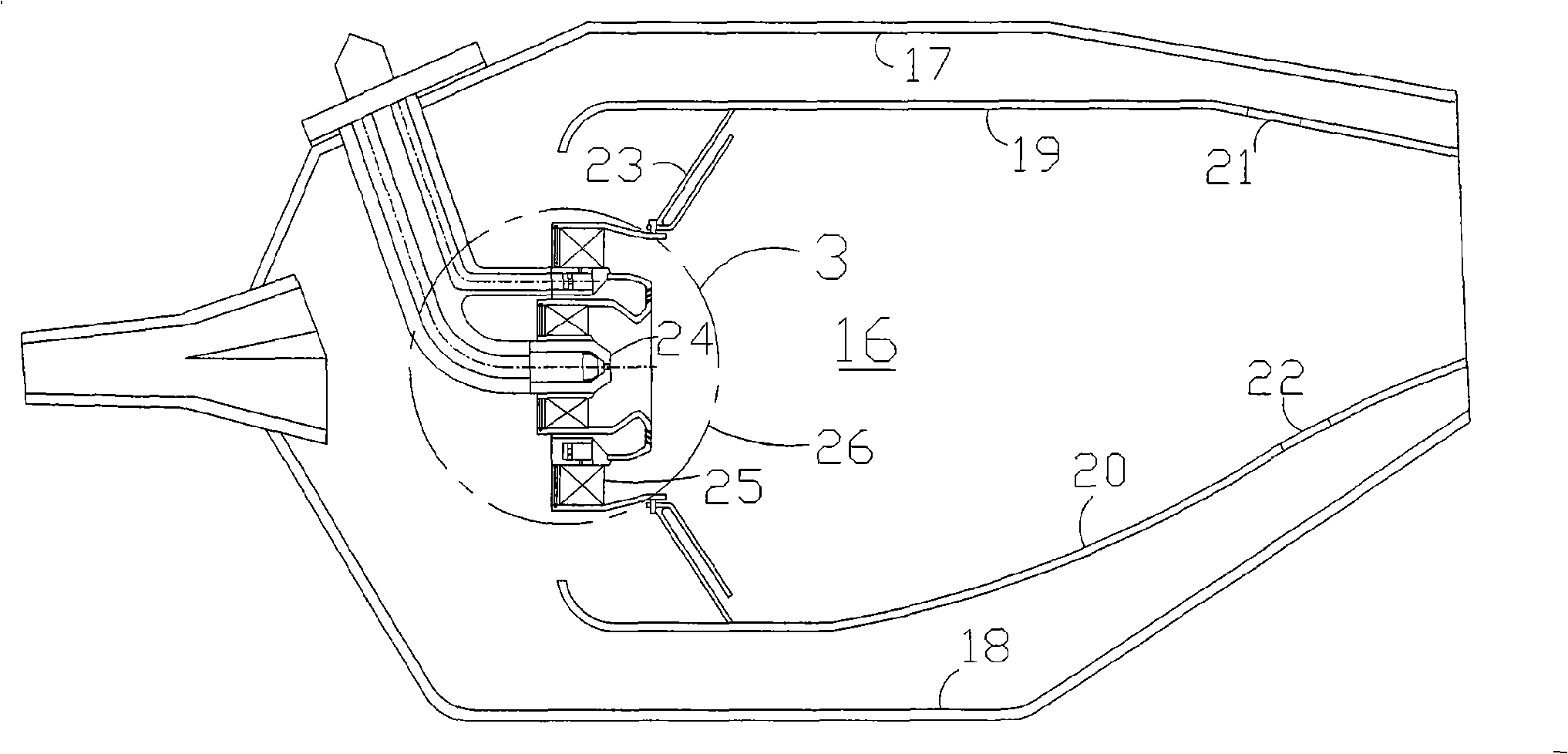

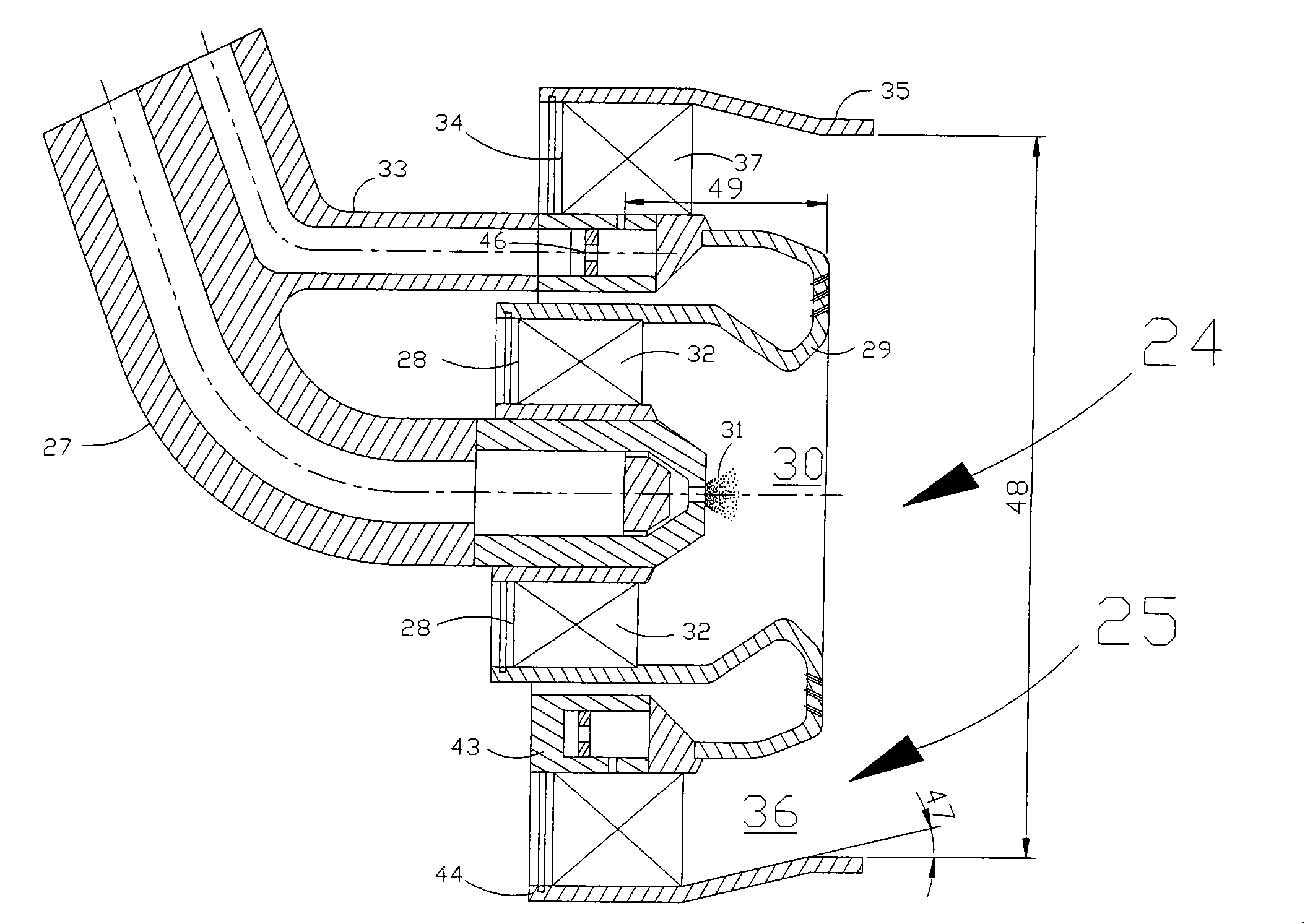

[0032] figure 1 It is a schematic diagram of an engine 10 , and the engine 10 includes a low-pressure compressor 11 , a high-pressure compressor 12 , a combustion chamber 13 , a high-pressure turbine 14 and a low-pressure turbine 15 . When the engine 10 is working, the air is compressed by the low-pressure compressor 11 and then enters the high-pressure compressor 12. The high-pressure air enters the combustion chamber 13 for combustion. Combustion, high-temperature and high-pressure gas is formed after combustion, and enters the high-pressure turbine 14 and the low-pressure turbine 15, thereby driving the turbines to do work. figure 2 is a schematic diagram of the combustion chamber 13, and the combustion chamber is a single-ring cavity structure. image 3 Yes figure 2 The enlarged view of area 3 in is the detailed structure of the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com