Method for simultaneously extracting lipid and protein from microalgae

A technology for extracting oil and protein, which is applied in the preparation methods of peptides, chemical instruments and methods, and oil/fat production. Easy, high fat and protein yield, avoids the effect of drying the algal flour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

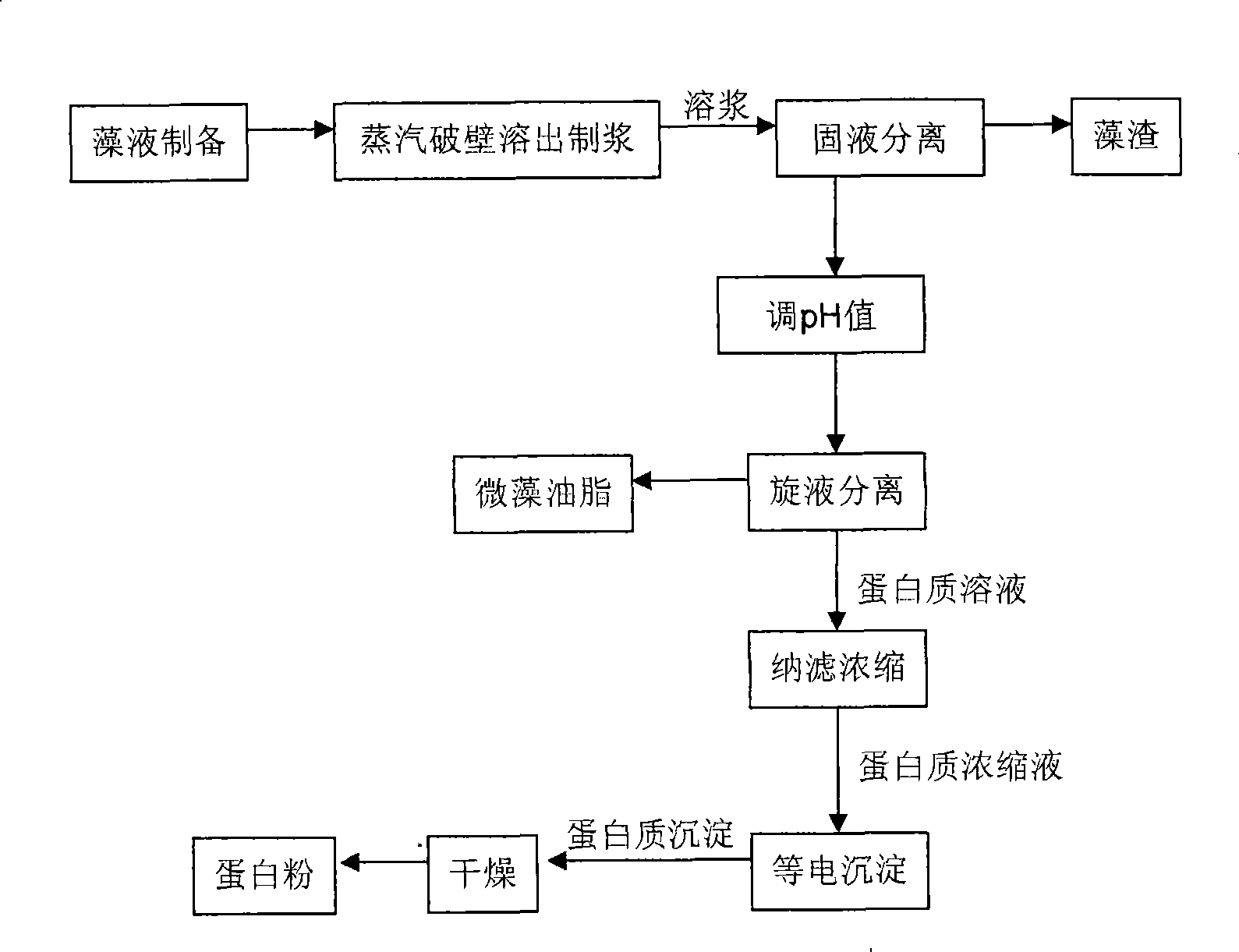

Method used

Image

Examples

Embodiment 1

[0019] Weigh 2000g of wet algae mud of Phaeodactylum tricornutum, add 2400g of distilled water to dissolve the algal cells, and adjust the pH value of the cell solution to 10. The microalgae cell solution was passed into a mechanically stirred reaction tank, and saturated steam was introduced, and the temperature in the tank was raised and maintained to 120° C., the stirring speed was 150 rpm, and the reaction was carried out for 30 minutes. Centrifuge the microalgae cell slurry at 4000rpm for 10 minutes to remove the microalgae cell residues to obtain a mixed solution, adjust its pH value to 7.0, use a small vortex type hydrocyclone to separate the mixed solution, and collect the upper oil phase to obtain algae Oil 45g 0. The protein-containing aqueous solution was filtered with a nanofiltration membrane (MWCO 300Dalton) to obtain a protein concentrate, and the pH value was adjusted to 2.5 with hydrochloric acid. After standing for 20 minutes, the supernatant was removed to o...

Embodiment 2

[0021] Weigh 2000g of wet algae mud of Phaeodactylum tricornutum, add 7000g of distilled water to dissolve the algal cells, and adjust the pH value of the cell solution to 14. The microalgae cell solution was passed into a mechanically stirred reaction tank, and saturated steam was introduced, and the temperature in the tank was raised and maintained to 140° C., the stirring speed was 150 rpm, and the reaction was carried out for 25 minutes. Centrifuge the microalgae cell slurry with a centrifuge at 4000rpm for 10 minutes to remove the microalgae cell residues to obtain a mixed solution, adjust its pH value to 6.8, use a small vortex type hydrocyclone to separate the mixed solution, and collect the upper oil phase to obtain algae. 47 grams of oil. The protein-containing aqueous solution was filtered with a nanofiltration membrane (MWCO 300Dalton) to obtain a protein concentrate, and the pH value was adjusted to 3.0 with hydrochloric acid. After standing for 20 minutes, the sup...

Embodiment 3

[0023] Weigh 2000g of wet algae mud of Phaeodactylum tricornutum, add 3000g of distilled water to dissolve the algal cells, and adjust the pH value of the cell solution to 7.5. The microalgae cell solution was passed into a mechanically stirred reaction tank, and the temperature in the tank was raised and maintained to 110° C. by passing saturated steam, and the stirring speed was 150 rpm, and the reaction was carried out for 10 min. Centrifuge the microalgae cell slurry with a centrifuge at 4000rpm for 10 minutes to remove the microalgae cell residues to obtain a mixed solution, adjust its pH value to 5.0, use a small vortex type hydrocyclone to separate the mixed solution, and collect the upper oil phase to obtain algae. 42 grams of oil. The protein-containing aqueous solution is filtered with a nanofiltration membrane (MWCO 300Dalton) to obtain a protein concentrate, and its pH value is adjusted to 4.0 with hydrochloric acid. After standing for 20 minutes, the supernatant i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com