Process and device for preparing gypsum whisker by semi-dry desulfurized fly ash and waste acid

A semi-dry desulfurization and gypsum whisker technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficult dehydration, small particle size of gypsum, etc., and achieve easy acquisition, simple operation and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

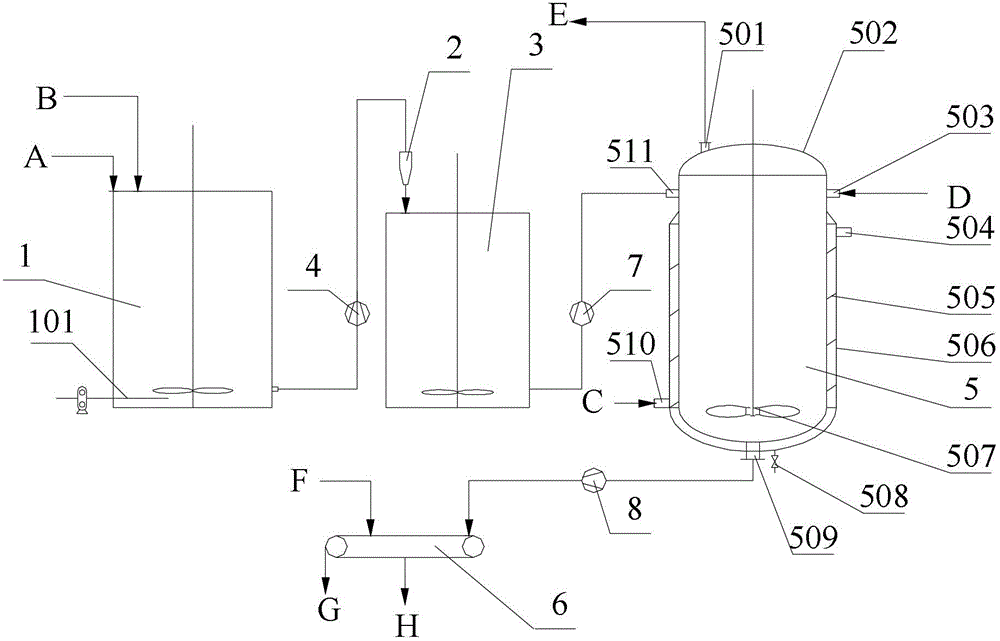

Method used

Image

Examples

Embodiment 1

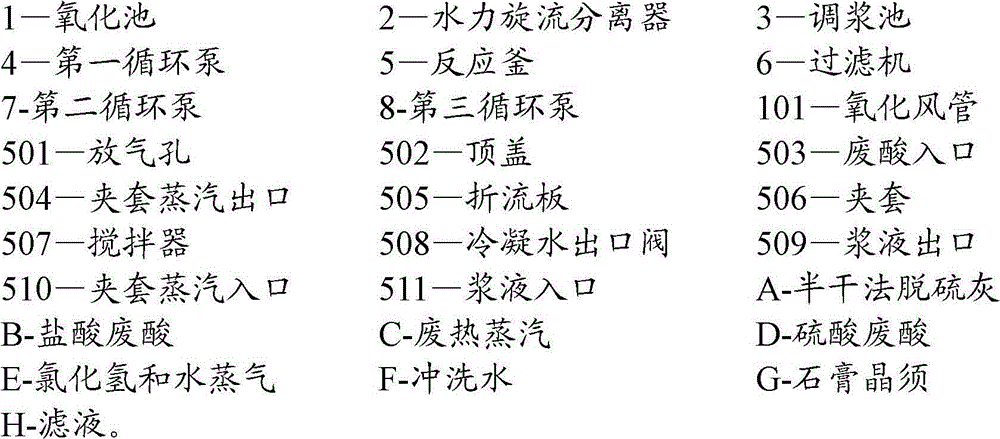

[0056] From semi-dry desulfurization ash component analysis is as follows (mass percentage):

[0057]

[0058] Using the above process to produce gypsum whiskers, wherein the CaCl in the reactor 2 At 5%, sulfuric acid concentration 1.2%, solid content 7%, temperature 98°C, reaction time 3h, the produced gypsum whiskers have a purity of 98.1%, an average length of 220 μm, and an aspect ratio of 85.

Embodiment 2

[0060] From semi-dry method desulfurization ash component analysis is as follows table (mass percentage):

[0061]

[0062] Using the above process to produce gypsum whiskers, wherein the CaCl in the reactor 2 At 7%, the concentration of sulfuric acid is 4%, the solid content is 5%, the temperature is 101°C, and the reaction time is 3.5h, the purity of the produced gypsum whiskers is 98.4%, the average length is 195μm, and the aspect ratio is 80.

Embodiment 3

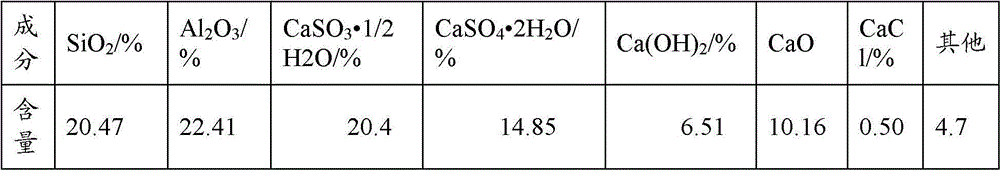

[0064] From semi-dry desulfurization ash component analysis is as follows (mass percentage):

[0065]

[0066] Using the above process to produce gypsum whiskers, wherein the CaCl in the reactor 2 At 5%, sulfuric acid concentration 0.8%, solid content 10%, temperature 102°C, reaction time 5.5h, the produced gypsum whiskers have a purity of 98.0%, an average length of 180 μm, and an aspect ratio of 70.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com