Binary rhenium alloys

a technology of rhenium alloys and tungsten alloys, which is applied in the field of forming rheniumtungsten alloys, can solve the problems of high-purity rhenium metals that fail in such testing at the grain boundary, and achieve the effects of improving mechanical properties, reducing ductility, and improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Six separate 200 gram portions of 99.9999% purity rhenium powder flakes (−200 mesh) obtained from Rhenium Alloys, Inc. of Elyria, Ohio were placed into separate beakers marked A, B, C, D, E and F, respectively. Ammonium metatungstate was dissolved in deionized distilled water and then added to the beakers labeled A, B, C, D, E and F, respectively, to provide the final concentration of tungsten shown in weight percent in Table 1 below. Additional water was added to each beaker, as necessary, to insure good wetting of the rhenium powders and good distribution of the tungsten compound throughout the powders. The contents of each beaker were stirred together until the liquid coated the powder particles uniformly. A control sample comprising the 200 grams of the same rhenium powder and distilled water (no tungsten compound was added) was placed in a beaker marked Control.

[0035] The beakers containing the wetted powders were placed on a hot plate and the volatile portion of the li...

example 2

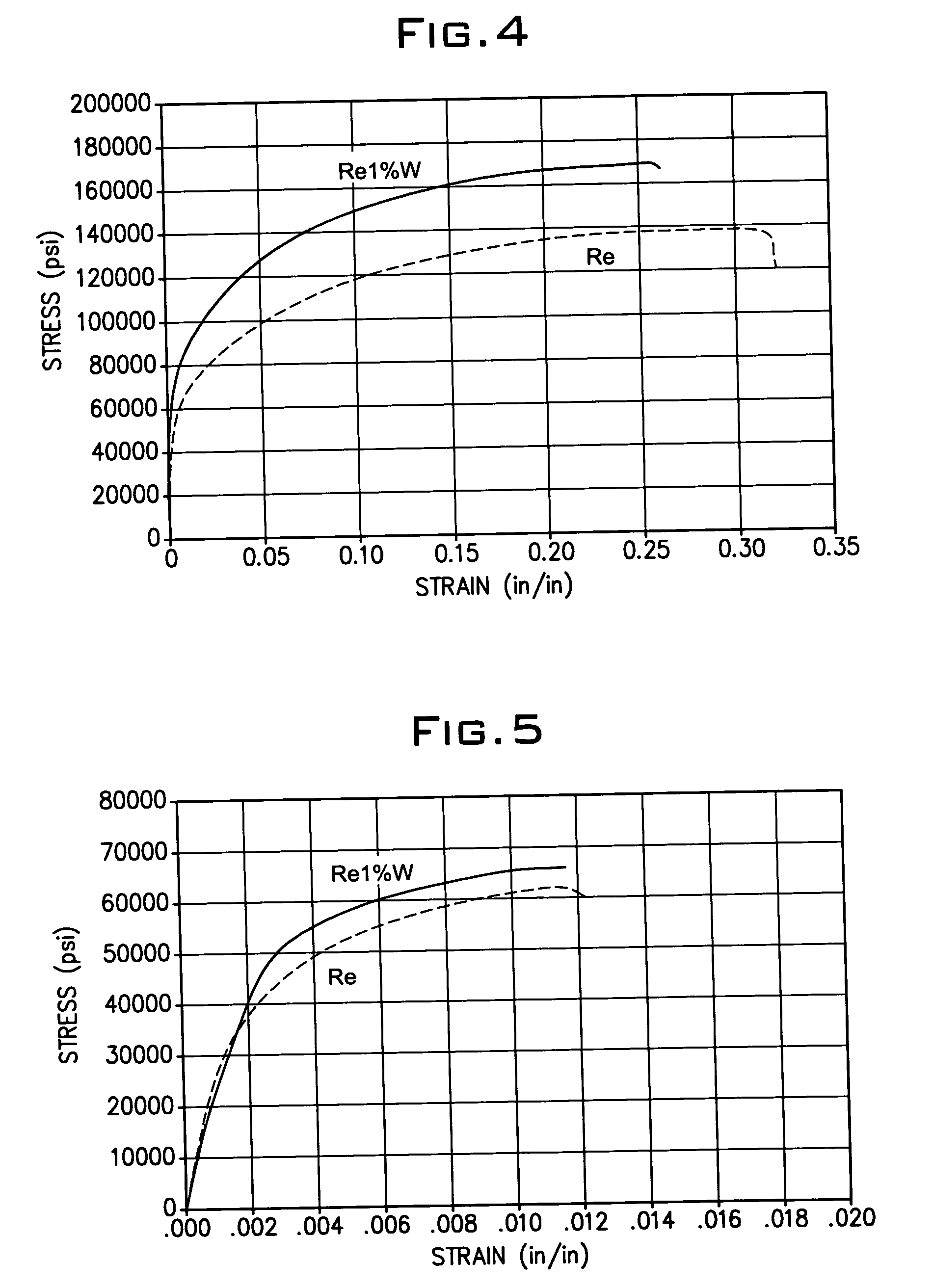

[0041] An 0.080 inch thick sheet of a rhenium-tungsten alloy containing 1% tungsten by weight (Re1% W) was formed using the materials and procedures described in Example 1. Tensile bars were cut from the sheet in accordance with ASTM E8-03 and ASTM E21-03a. Tensile bars were tested at room temperature (70° F.), at 2500° F. and at 3500° F. FIG. 4 is a graph of the longitudinal tensile stress-strain response of the Re1% W alloy (solid line) as compared to that of high-purity rhenium metal (dashed line) at room temperature. FIG. 5 is a graph of the longitudinal tensile stress-strain response of the Re1% W alloy (solid line) as compared to that of high-purity rhenium metal (dashed line) at 2500° F. FIG. 6 is a graph of the longitudinal tensile stress-strain response of the Re1% W alloy (solid line) as compared to that of high-purity rhenium metal (dashed line) at 3500° F. As shown in the graphs, the Re1% W alloy exhibited a higher longitudinal tensile stress-strain response than high-pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com